|

Title: |

1893 Article-Fraser & Chalmers Co., 1,000 H. P. Triple Expansion Steam Engine |

|

Source: |

Cassier's Magazine Sep 1893, pg. 332 |

|

Insert Date: |

11/28/2012 9:04:47 PM |

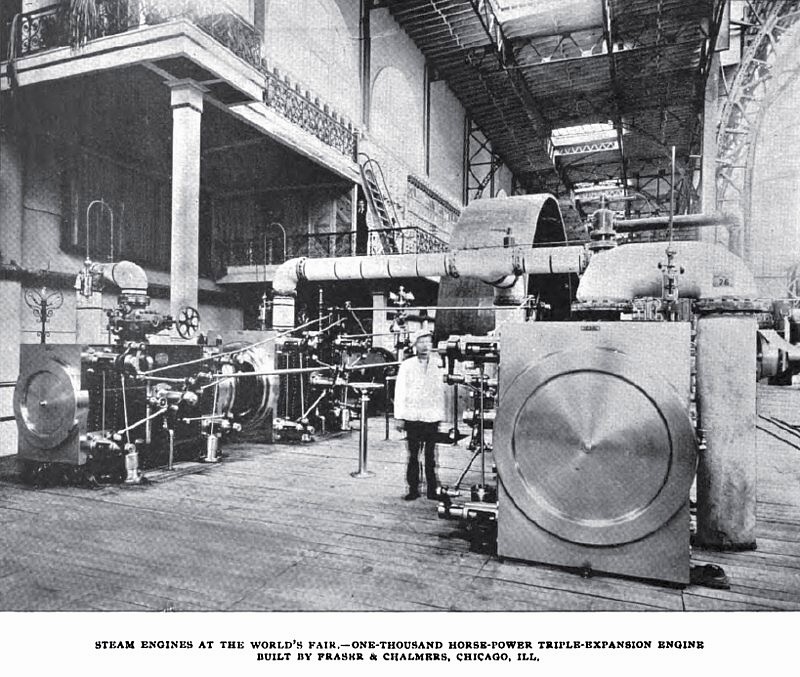

Of the Fraser & Chalmers engine, referred to in this list, a general view is given on the opposite page. The engine, which is rated at 1,000 horse-power and runs at a speed of 64 revolutions per minute, is of the four-cylinder, triple expansion design, having one high-pressure cylinder, 20 inches in diameter; one intermediate cylinder, 34 inches in diameter; and two low-pressure cylinders, each 34 inches in diameter, the stroke of all being 6o inches. The purpose of this arrangement of cylinders is, of course, to equalize the turning moment and the strains and power exerted on each crank as far as possible. All the cylinders are steam jacketed on the heads as well as on the sides. The valve gear is of the regular Fraser & Chalmers Corliss type. The cut-off gear of the high-pressure cylinder is always under control of the governor, but the novelty appears in the cut-off gears of the remaining cylinders.

If there are no sudden changes of load, the cut-off should be constant in the other cylinders in order to secure a uniform, minimum drop of power between these cylinders, the cut-oft depending upon the size of the receiver and cylinders; but if the load were suddenly and largely reduced there might remain steam enough in the receivers to cause the engine to speed up or run away even if all the steam were cut off from the high-pressure cylinder. On the other hand also, with the sudden imposition of a great increase of load the increased admission of steam in the high-pressure cylinder might not be sufficient to maintain the speed of the engine. To guard against these contingencies the cut-offs of the intermediate and low-pressure cylinders are connected with the governors by means of oil cataracts. A slow motion of the governor will not affect the intermediate or low-pressure cylinders, the cut-off cams being held in position by springs; but any sudden motion of the governor transfers itself instantly to the cut-off cams, which, after this influence has passed, again slowly recede to their normal position. In short, the cut-offs of the intermediate and low-pressure cylinders are changed only in cases of emergency, and not long enough to reduce the economy of the engine. The connecting pieces between the cylinders are made in halves so that they may be taken apart for convenience in examining cylinders and pistons. The engine is of course used condensing, but the condenser in this case is not of the Fraser & Chalmers design, but one furnished by the Conover Manufacturing Company of New York, for exhibition in connection with this engine. |

|

1893 Fraser & Chalmers Co., 1,000 H. P. Triple Expansion Steam Engine

1893 Fraser & Chalmers Co., 1,000 H. P. Triple Expansion Steam Engine

|

|