|

Title: |

1893 Article-E. P. Allis & Co., Corliss Steam Engine |

|

Source: |

Cassier's Magazine Jul 1893, pg. 226 |

|

Insert Date: |

11/22/2012 8:44:59 PM |

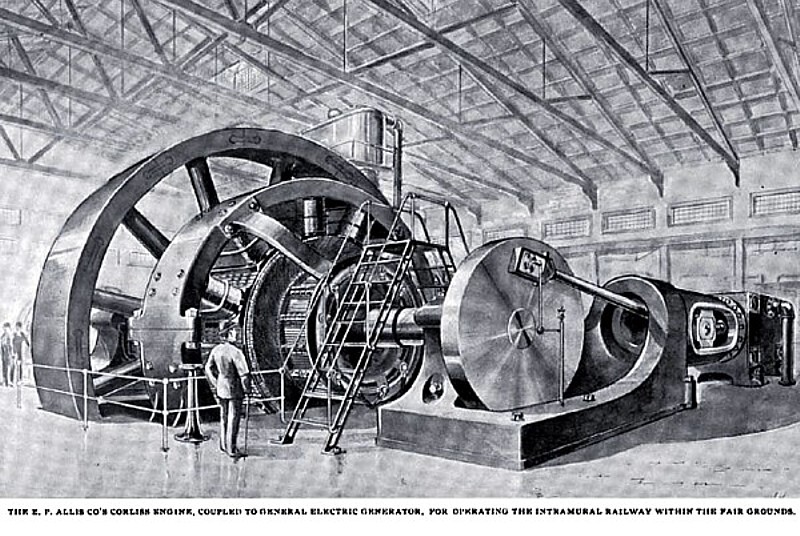

One of the features of the transportation facilities at the Fair is the Intramural Railway, which, as is generally known, is operated electrically. The current for the line is supplied by a gigantic 2,000 horse-power multi-polar railway generator, built by the General Electric Company, of New York, and driven by a correspondingly imposing cross-compound condensing engine of the Reynolds-Corliss type, made by the E. P. Allis Company, of Milwaukee, Wis. The engine and generator, while not, strictly speaking, one of the regular exhibits, form an interesting addition to the Machinery Hall display, and reference to them in connection with the present account of the World's Fair steam engines is, therefore, not inappropriate. They are set up in the Intramural Railway powerhouse, and enjoy the distinction of being the largest combination of this kind in the world. The generator itself is a twelve-pole compound wound machine. Each pole is first wound in usual spool fashion and then securely bolted to the massive iron field constructed of two enormous semi-circles of cast-steel, bolted together the lower of which is provided with supporting feet. This field is fifteen feet in diameter, and weighs considerably over 80,000 pounds. The breadth is just three feet. The armature is of the iron clad, ventilating type; that is to say, each of its separate windings is buried in its individual mica-lined slot in the exterior surface of the laminated body. The armature is wound on a cast iron spider weighing over f1fteen tons, which is rigidly keyed to the ponderous shaft of the immense engine. The diameter of the armature is ten and a half feet; its breadth, over three feet, and its weight, over thirty-five tons. The shaft to which it is keyed is two feet in diameter, and weighs fifty-f1ve tons. The commutator is seven feet six inches in diameter. The temperature of the armature, under full load, will not rise over 40 C. above the average temperature of a room.

The brush holders, of which there are twelve sets, corresponding to the twelve poles, are of a novel design. They are carried on an outside brush holder yoke, supported on one side of the field magnet frame, and are moved into position conveniently by means of a special shifting gear, operated by a hand wheel. The brushes are easily accessible from a staircase passing over the revolving shaft. The generator is entirely independent of the engine, with the exception of the armature, which is f1tted to the shaft.

The efficiency of this enormous creation is claimed to be ninety-six per cent. In its mechanical construction special provision was made for allowing a wide fluctuation of load and speed without affecting the efficiency of the machine. The number of revolutions per minute at which it runs is seventy-five. It is wound for 600 volts.

The engine driving this mammoth generator, and to which brief reference has already been made above, has a high-pressure cylinder thirty-two inches in diameter, and a low-pressure cylinder sixty-two inches in diameter, the stroke being sixty inches. Both engine and generator run at a speed of seventy-five revolutions per minute. The weight of shaft and its load is about 160 tons. The fly-wheel is twenty-five feet diameter and weighs eighty-two tons. A thirty-two by sixteen-inch Reynolds vertical air pump and condenser, fitted with a Corliss valve gear, works in connection with the engine, which is specially heavy in design and so arranged that either side is capable of handling 2,000 horse-power in case of necessity. |

|

1893 E. P. Allis & Co., Corliss Steam Engine

1893 E. P. Allis & Co., Corliss Steam Engine

|

|