|

Title: |

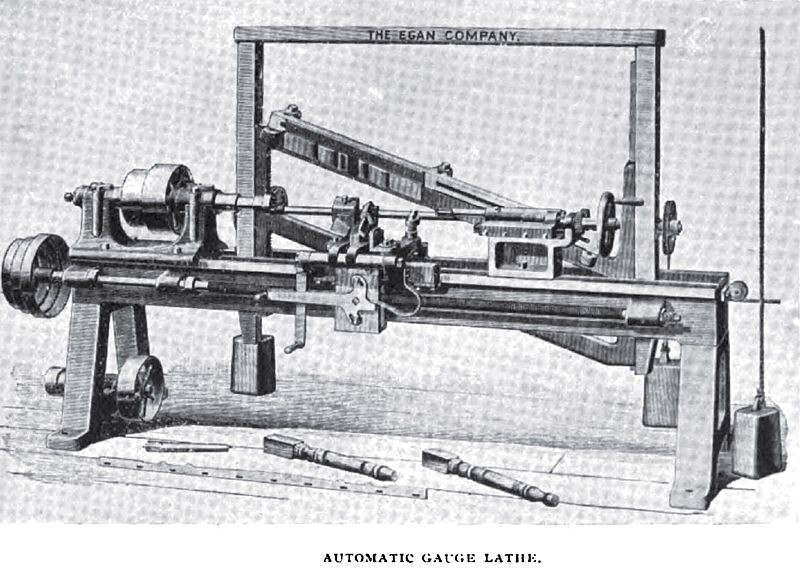

1893 Article-Egan Co., Automatic Gauge Lathe |

|

Source: |

Cassier's Magazine Jan 1893, pgs. 233-237 |

|

Insert Date: |

11/13/2012 9:32:56 PM |

|

The Egan Company of Cincinnati, Ohio, have recently produced an automatic gauge lathe, designed for extra large work. It turns stock up to six inches in diameter and up to forty-two inches long. Heretofore it has been considered impossible to turn stock six inches in diameter on an automatic gauge lathe. Work of the above diameter has always been turned by hand and at a great cost. The bed is made in one solid piece, of extra width, planed true, with “V"s” for the sliding rest to run back and forth on, and a centre bar on which is attached the form or pattern for roughing out the stock ready for the back knife to make the finishing cut. The head stock is furnished with journal boxes of extra length lined with genuine Babbitt metal, perfectly rigid to receive the large spindle, and on this spindle is a cone pulley with two speeds and an extra speed to drive the feed, connecting a short countershaft below, which is part of the machine. The tail stock is made on an improved plan, and is provided with gears and screws so as to apply the power as near the centre as it is possible to get, bringing same exactly in line with the driving centre. The sliding carriage is made to move back and forth along the ways by a screw, operated by a cone pulley from the feed shaft below. Provision is made for opening and closing the nut automatically for moving the carriage back and forth. It is also fitted up with two adjustable arms, one for the roughing stock to fit the thimble-plate and the others for roughing out the molded part of the stock, ready for the hack knives to make their cut. The back knife attachment is connected to the bed, supported at the top and held perfectly rigid. The bar which carries the back knives is made to slide up and down in planed ways, countered by weights and controlled by the sliding rest. By this arrangement the back knives are made to act on the stock close to the thimble-plate or support, thereby allowing the back knives to cut perfectly smooth and free. The back knives are attached to the bar and adjust on the frame and can be regulated to suit the different diameters to be turned. |

|

1893 Egan Co., Automatic Gauge Lathe

1893 Egan Co., Automatic Gauge Lathe

|

|