|

Title: |

1893 Article-Watertown Steam Engine Co., Duplex Tandem Compound Automatic Steam Engine |

|

Source: |

Cassier's Magazine May 1893, pgs. 43 & 44 |

|

Insert Date: |

11/12/2012 8:14:22 PM |

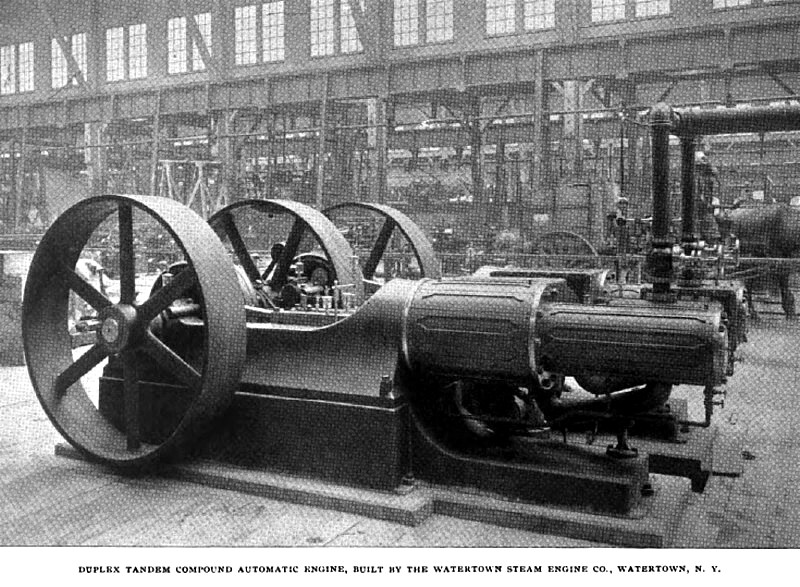

A duplex, tandem-compound condensing engine of new design is shown by the Watertown Steam Engine Company, of Watertown, N. Y. It has two nine-inch high-pressure, and two sixteen-inch low-pressure cylinders, all of fourteen-inch stroke. In the governor of this engine, unlike other shaft governors which secure a varying cutoff by shifting a single eccentric across the shaft, the movement is obtained by a mechanism which is, in effect, a double eccentric turning on the shaft. Particular attention is called to the fact that its effect is to increase the steam lead as the load on the engine is increased and as more steam is needed; on the other hand, as the load falls off, less steam is required and the steam lead is decreased, with the further result of reducing compression. The governor in this engine, it should be observed, is the same in principle and action as the regular Watertown engine governor used in the other automatic engines of the company.

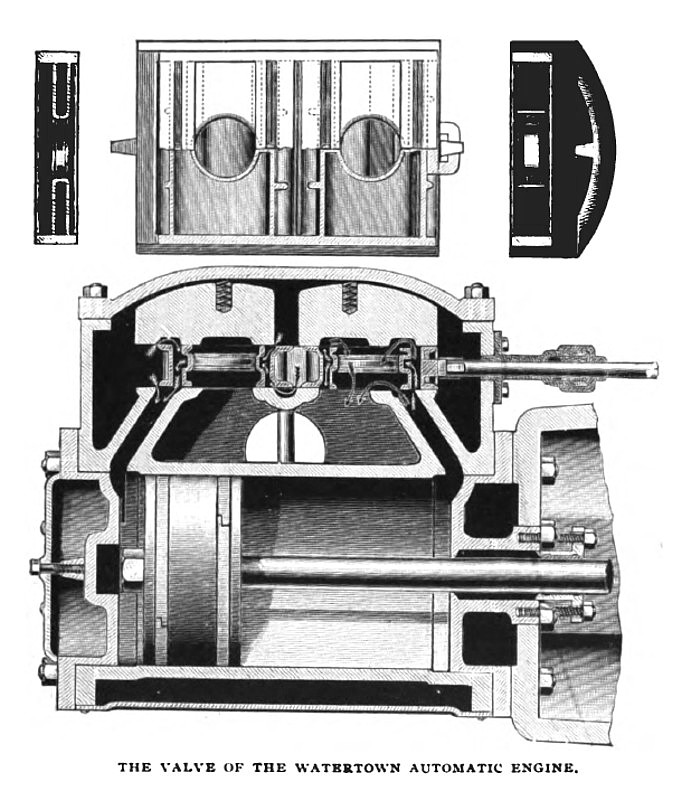

The valve, of which a sectional view is given, is also of the regular Watertown design, and has port openings so arranged as to admit steam to the cylinder ports through four different openings at once, thus giving a- port opening four times the travel of the valve and securing very prompt action upon piston. The valve also exhausts steam through four openings at once. The valve is accurately fitted to its place and is carefully scraped. On the back of the valve is a pressure plate, balancing the valve so easily, it is claimed, that it can be worked readily by one hand while under steam. This pressure plate is held in its place by a small spring at the back, holding it to its position in spite of wear and acting also as a relief valve when excessive pressure from water in the cylinder throws the valve from its seat. The valves of all four cylinders are controlled by the governor, insuring an even division of the load.

All the cylinders are neatly jacketed with closely fitting iron staves. The cylinder heads also are jacketed, and the spaces between the high and the low-pressure cylinders are covered by extensions of the high-pressure cylinder jackets. The removal of a single panel at any time gives easy access to the stuffing-boxes and cylinder heads. The whole engine, which runs in conjunction with a Knowles condenser, is mounted on a neat and substantial sub-base, with an extension on which are fitted supports for the high-pressure cylinders. These supports are so made that they can be adjusted not only horizontally, but also vertically, to meet any possible movement of the high-pressure cylinders due to expansion under heat.

The frame of the engine is very heavy, with longitudinal and cross ribs securely bracing it. The working parts are placed as low as possible, bringing the centre lines at about the surface of the bed, so that all the strains are brought in line with the lines of greatest resistance. All oil from the cross-heads, connecting rods, and cranks is caught in the bottom of the frame, whence it can be drawn off. The crank-shaft is slotted from a solid, forged block. The connecting rods are of forged iron with square straps and boxes, the latter being of composition metal. The cross-heads are made of crucible steel, and have large bearing surfaces, both cross-heads and guides being carefully scraped.

Besides the engine shown, the builders turn out a single-cylinder, high speed, automatic engine, a cross compound, and a plain tandem-compound. They are also prepared, however, to build triple-expansion engines of from 200 to 500 horse-power. |

|

1893 Watertown Steam Engine Co., Duplex Tandem Compound Automatic Steam Engine

1893 Watertown Steam Engine Co., Duplex Tandem Compound Automatic Steam Engine

1893 Watertown Steam Engine Co., Automatic Steam Engine (Valve Section)

1893 Watertown Steam Engine Co., Automatic Steam Engine (Valve Section)

|

|