|

Title: |

1895 Article-Rivett Lathe Mfg. Co., Rivett Bench Lathe |

|

Source: |

Chicago Journal of Commerce, 21 Mar 1895, pg. 14 |

|

Insert Date: |

11/6/2012 8:01:02 PM |

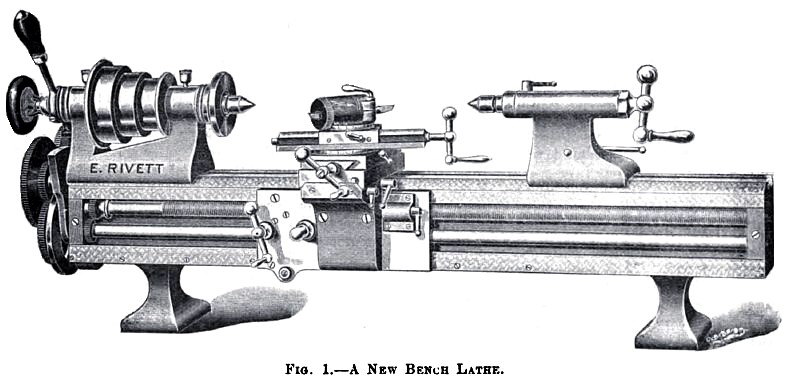

A NEW BENCH LATHE.

We present herewith an engraving of a bench lathe, the design of which is the outcome of an order piven by Mr. Herman Dock, a mechanical engineer of Philadelphia, to the Faneuil Watch Tool Company, Boston, all necessary time and carte blanche being given to construct the best possible lathe, which was designed by Mr. Edward Rivett, manager of the above named company.

The regular head and tail stock of the "No. 4 Rivett lathe" are used, but the bed is made deeper and longer to admit of the rack, screw and feed rod.

The carriage is placed on the side of the bed instead of on top, and in time not so much exposed to chips and dirt, and can also be run past the tail stock out of the way when desired; as for instance, when the slide rest is removed from the carriage and clamped directly to the bed, for use in that way, which can be readily done.

The other special features of this lathe consist of the improved slide rest, a. friction clutch on the carriage and an automatic chuck closer by which the chucks, which are of the standard draw-chuck pattern, with a capacity to take work through the spindle from 1/32 inch to ½ inch diameter can be closed or opened while the lathe is in motion. We give a longitudinal section of head-stock spindle and bearings which shows the construction of this chuck-closing device. It is there seen to be a simple construction, consisting of a movable abutment for the draw tube instead of having it about as usual directly upon the end of the spindle. The mechanism consists of a sliding collar moved by a lever, this collar operating two dogs or levers that press against a collar placed at the end of the spindle, and force the draw tube back. This arrangement, of course, leaves the hand wheel to be used in the ordinary manner when a chuck is first put in place or when for any reason it is preferable.

Both the live and tail stock spindles are made of tool steel hardened and ground, the former being 2 1/8 inches diameter and with bearings 2 3/8 inches long. The thrust is taken by the front bearing, an 1 the endwise adjustment of the spindle is made there, a taper sleeve being provided for taking up wear in the rear bearing.

By this construction the trouble which comes from expansion and contraction of the spindle in such lathes is done away with.

The lead screw can be made use of the full length of the lathe between centers, and with the gears supplied, cuts threads from 8 to 100 threads per inch. There is an automatic cross-feed which operates to the full capacity of the lathe—8 inches, and a follow rest by which delicate work can be turned the full length of the lathe.

The rack and gears are of tool steel, and all important bearings are hardened and ground for the sake of securing initial and continued accuracy, and no pains have been spared to make the lathe as fine as such a tool can be made.

The slide rest furnished with this lathe is especially adapted for milling operations, and we give full size engravings of a few milling cutters the teeth of which were milled by its use. |

|

1895 Rivett Lathe Mfg. Co., Rivett Bench Lathe

1895 Rivett Lathe Mfg. Co., Rivett Bench Lathe

|

|