|

Title: |

1895 Article-New Doty Mfg. Co., Belt Power Punch & Shears |

|

Source: |

Chicago Journal of Commerce, 07 Feb 1895, pgs. 18 & 19 |

|

Insert Date: |

11/5/2012 1:33:29 PM |

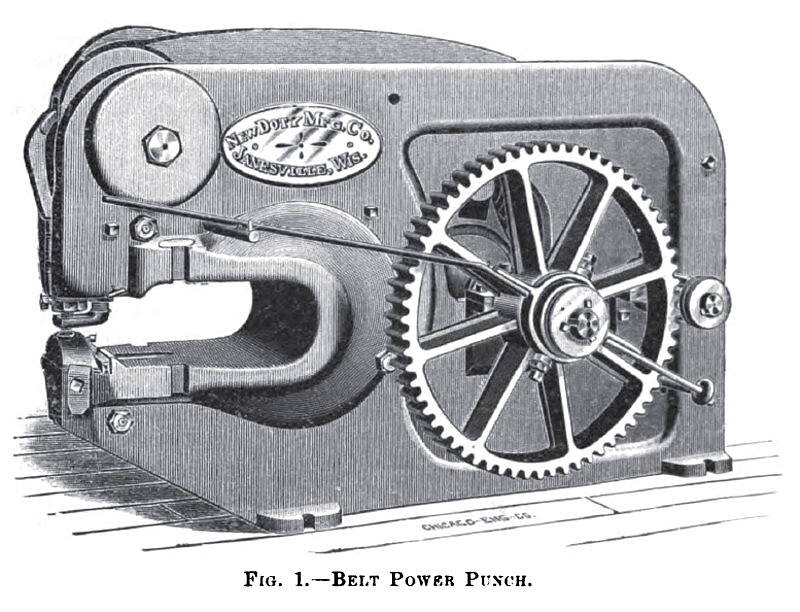

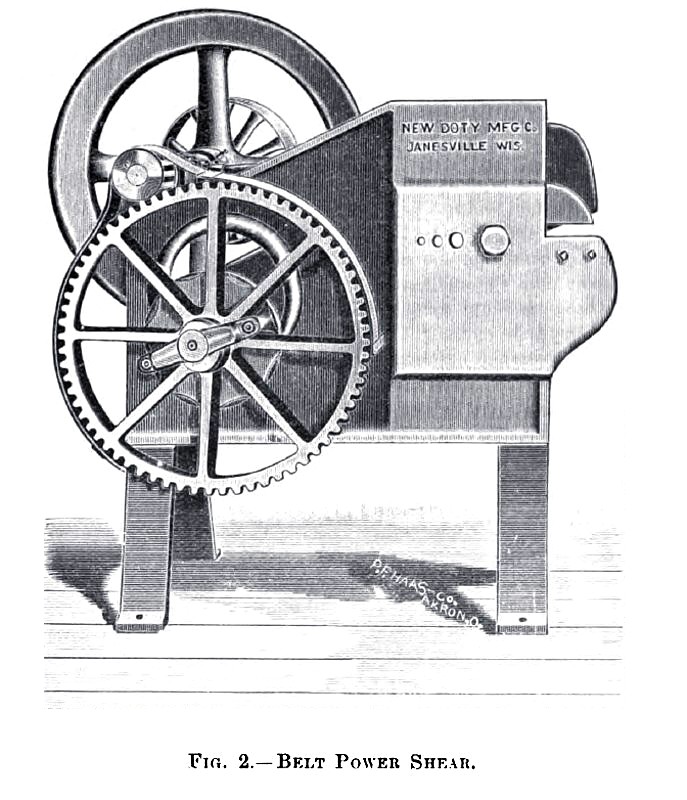

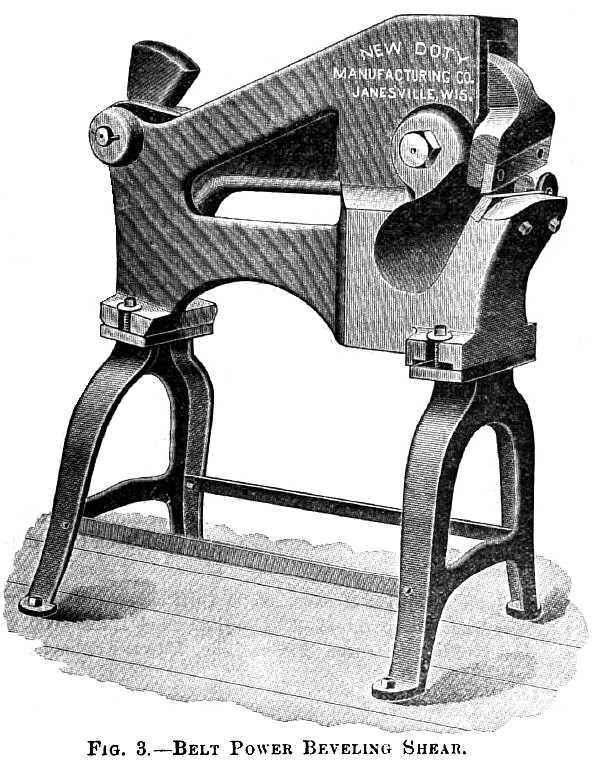

NEW DOTY PUNCHES AND SHEARS

The accompanying engravings represent three new types of punches and shears designed by the New Doty Manufacturing Company, Janesville, Wis. The first, Fig. 1, is made in 10 sizes and is intended for use of boiler makers and sheet metal works. The machine is powerfully back geared, so as to easily do to work for which it is designed. The boxes for the eccentric and balance wheel shafts are cast on the frame, and the eccentric and eccentric shaft are cast in one piece. The machines vary in size from ¼ inch hole in a ¼ plate to a 1 inch hole in a 1 inch plate, and the depth of jaw varies from 2 inches to 37 inches. The punches and dies can be fitted to the machine without stopping the flywheel. The motion is controlled by a clutch operated by a hand lever or treadle, as may be desired. The machine can be used to punch flanges, as the distance from the front to the center of the punch can be made but ¾ inch. The stripper is adjustable to 0.001 part of an inch. These machines are arranged so that shearing blades can be put on in place of the punch and die, when they can be used for shearing plates to the full depth of the throat.

The shear shown in Fig. 2 will cut 5/8 by 5 inch flat iron. This machine is made in six sizes, in all of which the knives for flat or round iron are independent of each other, and both sets of knives are at all times ready to use. The round iron knives are made the reverse of the iron and therefore do not flatten it in cutting. The boxes and eccentric are formed as in the belt power punch. The eccentric is so designed as to allow a short stop after each stroke, in order that the work may be adjusted for the next stroke. The machines are adapted to run at 25 or more strokes per minute, the speed being governed by the ability of the operator to handle the material.

The beveling shear, Fig. 3, is made in two sizes—the smaller to bevel plate ½ inch or less in thickness and the larger to bevel plate 1 inch or less. These machines will bevel throat sheets, the flanges of domes and sheets bent to a curve, in addition to beveling straight sheets. There is no tipping up of the metal while being cut, and all tendency to twist or move sideways is overcome by the adjustable stop shown in the engraving. This machine is like the others in the construction of the eccentric. |

|

1895 New Doty Mfg. Co., Belt Power Punch

1895 New Doty Mfg. Co., Belt Power Punch

1895 New Doty Mfg. Co., Belt Power Shear

1895 New Doty Mfg. Co., Belt Power Shear

1895 Article-New Doty Mfg. Co., Belt Power Beveling Shear

1895 Article-New Doty Mfg. Co., Belt Power Beveling Shear

|

|