|

Title: |

1895 Article-Langelier Manufacturing Co., Multiple Spindle Drilling Machine |

|

Source: |

Chicago Journal of Commerce, V66 #1, 03 Jan 1895, pg. 18 |

|

Insert Date: |

10/28/2014 5:04:00 PM |

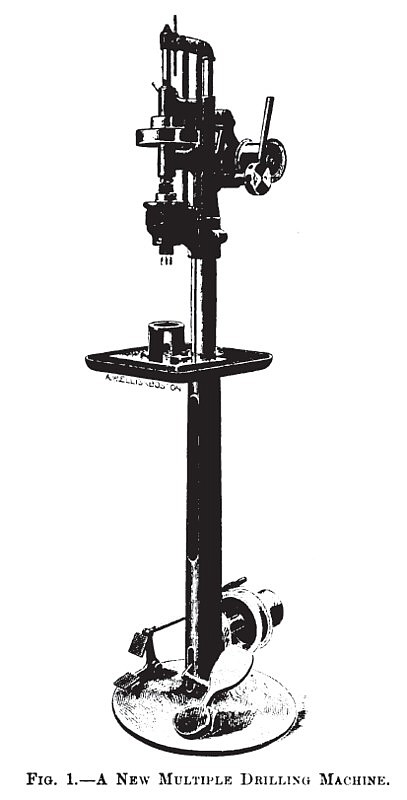

A NEW MULTIPLE SPINDLE DRILLING MACHINE.

We present on this page illustrations of a new multiple spindle drilling machine, intended mainly for manufacturing operations, and to drill almost any required number of holes with any desired grouping, and of various sizes and depths; these it drills in about the same time as would be required to drill the largest or deepest with a single-spindle drill.

No jig is usually employed with the machine, though, of course, one can be used if it is preferred or is necessary.

Motion is given to the various spindles by means of cranks, which are formed ou their upper ends, these cranks engaging with a plate, which maybe called a wrist plate, and is given the required circular motion by a crank, which is formed on the lower end of the main spindle, so that the plate serves merely as a connection for the various cranks and performs the same office as in performed by the side rods of a locomotive, and in the same manner.

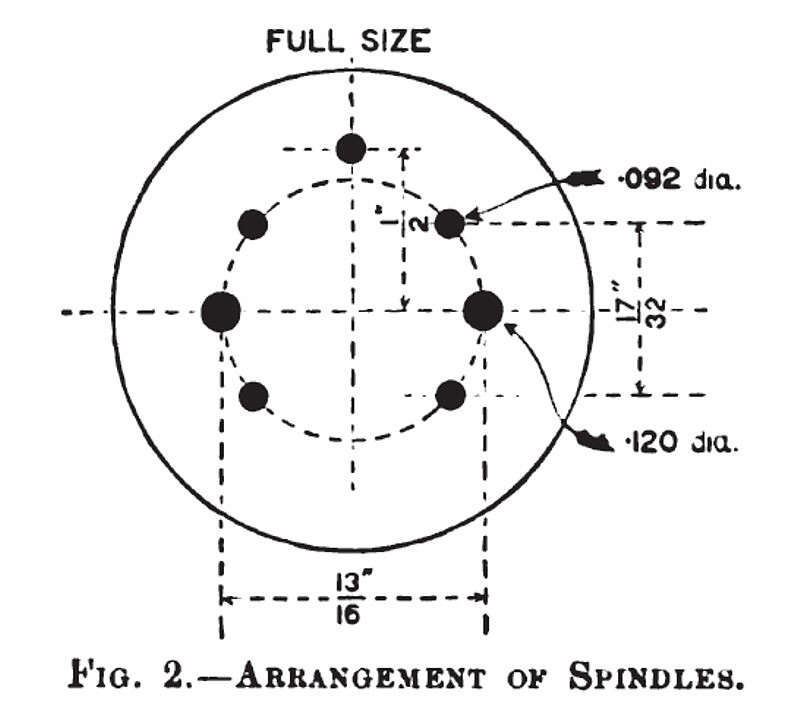

By this construction, there is scarcely any limit to the number of holes that can be drilled simultaneously, and, in fact, we have before us photographs of a machine built upon the same principle, in which the wrist plate is extended laterally until it becomes a long bar and gives motion to 162 drill spindles, arranged in a double straight row. The particular machine illustrated is for drilling the back end of a Bell telephone receiver case, and the spindles are arranged as shown by the diagram, Fig. 2, which is full size.

The action of these machines being perfectly balanced, is smooth and noiseless, and they can be run as high as 2,500 turns a minute. Being driven entirely by one pulley, all complications of belts and gearing are avoided, and each drill is as strongly driven as if inserted in the end of the main spindle. All spindles are automatically lubricated from a single oil cup.

On the table of the machine is shown a fixture for correctly holding the article to be drilled. Other positions, sizes and numbers of drills can be used on the same machine by simply changing the bearing block through which the drill spindles pass. The fixture on the table can also be changed to suit other work.

A very large variety of work can be expeditiously done on these machines, and they have been built for electrical work on wood, fiber and metal, bicycle hubs, guns, sewing machine work, clock frames, etc., locks, hinges and other hardware, jacquard loom work, perforated metal, brush and novelty work of various kinds. The same system can also be applied for tapping a number of holes at once.

The makers are the Langelier Manufacturing Company, 67-69 Clifford Street, Providence, R. I. |

|

1895 Langelier Manufacturing Co., Multiple Spindle Drilling Machine

1895 Langelier Manufacturing Co., Multiple Spindle Drilling Machine

1895 Langelier Manufacturing Co., Arrangement of Spindles

1895 Langelier Manufacturing Co., Arrangement of Spindles

|

|