|

Title: |

1892 Article-Buffalo Woodworking Machine Co., Planing & Matching Machine |

|

Source: |

American Machinist, 01 Dec 1892, pg. 3 |

|

Insert Date: |

10/29/2012 1:05:13 PM |

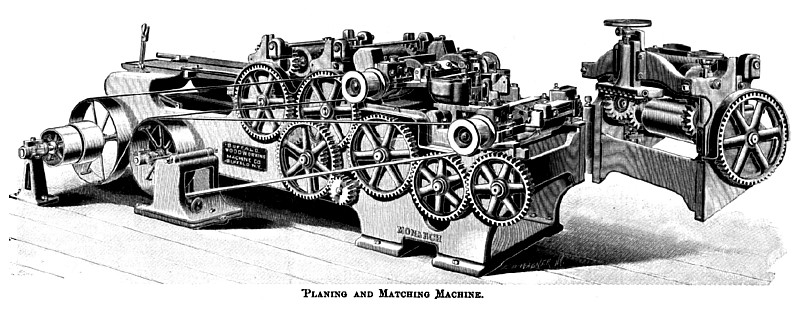

Planing and Matching Machine.

We present with this an illustration of a new planer and matcher which has been built by the Buffalo Wood-working Machine Co., of Buffalo, N. Y. In designing this machine special attention has been given to strengthening the parts which give’ most trouble from breakages, and to so arrange that there shall be no delays from these or on account of belts being too loose or too tight, facilities being provided by which the latter can be instantly tightened or loosened in accordance with the work.

The upper cylinder bearings are 2½ inches in diameter, 9 inches long; under cylinder, 2¼ inches in diameter, 9 inches long; matcher spindles, 2 inches in diameter. F. H. Crafts’ patent journal box is used to carry these bearings, and the arrangement is such as to give exceptional immunity from heating and injurious wear.

The cylinders are made from crucible steel forgings, and are slotted on four sides. The pulleys on cylinders have a taper fit, and are forced in place under powerful pressure. There are six feed rolls 8 inches in diameter, all double-geared, and they will maintain a parallel position under all conditions. The shafts in the rolls are of steel, 1-7/8 inches in diameter. Both matcher spindles and the guide bar can be moved simultaneously across the whole width of machine, or matcher spindles can be moved independent of each other, which provides for uniform wear of the bed-plates, pressure bar and chip breaker. The frame is divided, to make the under cylinder more accessible, and this is regarded by practical men as an important improvement.

There are tighteners on the matcher and cylinder belts. The belts are made endless, and all slack is taken up with the tighteners, and the belts will run for years without being cut.

In case a thick board enters the machine, for instance, instead of slacking up on the feed belt, the tightener on the cylinder belt is pulled up, which keeps the cylinder up to speed until the board passes through,when the belt can be relieved of the extra strain, and goes on as before. Again, in changing from thin stuff to thick, instead of having to cut and thus tighten the belts, which are found to be too loose, it is only necessary to move a lever, which gives the desired tension for the job, which tension can be released when returning to thin lumber, so that just sufficient belt tension, and consequently just sufficient pressure on the bearings to do the work, are all that are ever needed.

The pressure plate over the under cylinder is made hollow. Diagonal holes are drilled to meet this. Rubber hose connects with a fan. When the machine is in motion, the hollow space is filled with air, which escapes through the diagonal holes, blowing all chips and dust from the lumber, leaving it clean and bright. This machine is also provided with F. H. Crafts’ patent chip breaker, patent pressure bar, patent loose pulley, and other new features for which patents are pending.

If desired, the machine can be arranged to make two matched boards out of one strip, thus doubling its capacity. Counter-shaft has tight and loose pulleys 14 inches in diameter, 8½-inch face, and should make 950 revolutions per minute. The pulleys on cylinders are 5 inches in diameter, driving pulleys on counter-shaft 24 inches in diameter, making the cylinders turn 4,560. The cylinders can be run up to 5,000 with safety, if desired. Shipping weight, about 8,000 pounds. Can be built any width desired. |

|

1892 Buffalo Woodworking Machine Co., Planing & Matching Machine

1892 Buffalo Woodworking Machine Co., Planing & Matching Machine

|

|