|

Title: |

1893 Article-Fielding and Platt, Gas Engine |

|

Source: |

Engineering Magazine, V55, 27 Jan 1893, pgs 95 & 100 |

|

Insert Date: |

6/21/2012 9:01:53 PM |

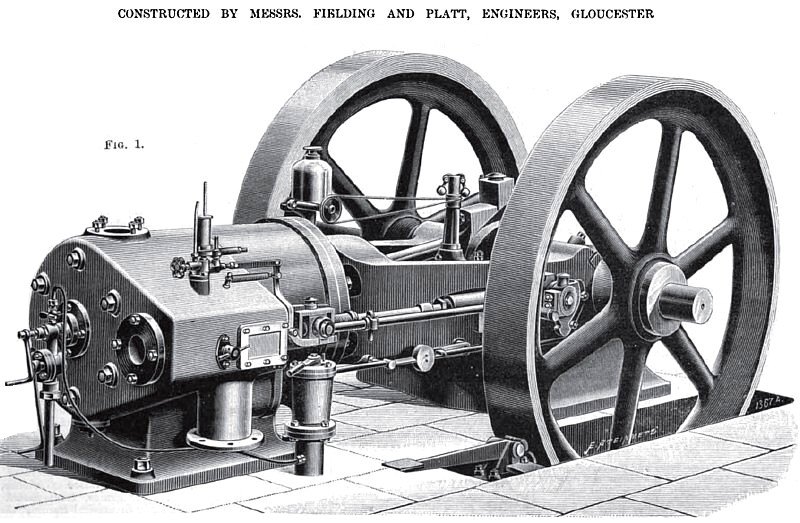

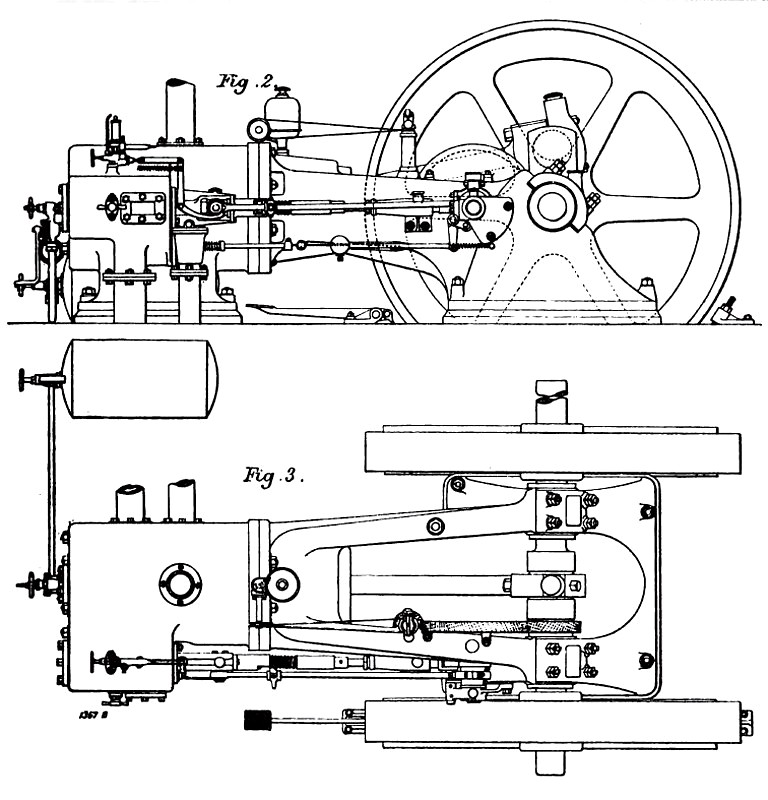

30 HORSE-POWER "FIELDING" GAS ENGINE.

We illustrate on page 95 a gas engine of 30 nominal horse-power, recently built by Messrs. Fielding and Piatt, of Gloucester, and capable of indicating 100 horse-power at a speed of 160 revolutions per minute. The engine works upon the "Otto" or "Beau de Koch as" cycle, the arrangement of the valve gear being, however, different to other engines of this type. A general view of the engine is shown in Fig. 1, whilst Figs. 2 and 3 show it in elevation and plan respectively. The working charge is admitted and the waste products exhausted by means of a simple mitre-seated valve, through inlet and outlet ports controlled by the movements of a piston valve which receives independent motion from an eccentric, which also operates the timed ignition valve. This valve was illustrated diagrammatically in our issue of July 31, 1891. The valves are placed horizontally by the side of the cylinder, an arrangement, which permits of very straight and direct pipe connections for gas and exhaust, the air being drawn through the cylinder base, which acts as a muffle. The main mitre-valve is worked from a cam by a rod leading direct to the valve.

The governor is of the high speed ball type acting upon a hit-and-miss gear interposed between the gas valve and its cam. The engine is fitted with a new starting gear recently patented by Mr. Fielding.

The new gear consists of a small reservoir of about the size of the cylinder jacket, which, after the engine has once been started, is charged with compressed air at a pressure of about 50 lb. per square inch by the engine itself when being stopped, thus utilizing the power stored up in the flywheels for use when re-starting the engine. The action of starting is as follows: The engine crank being placed slightly in advance of the dead centre nearest to the cylinder, gas is admitted by a small cock to the combustion chamber, from which the air is allowed to escape at a small pipe provided with a stopcock and terminating in a jet near to the top of ignition tube of Bunsen chimney.

When the air has been driven out and the gas begins to escape at the jet, it becomes ignited, and as soon as it burns with a steady flame, showing that an ample supply of gas is present in the cylinder, the outlet and inlet cocks are closed. Compressed air is then turned into the cylinder, and the igniting valve being open, as soon as an explosive mixture is formed and sufficient pressure attained, the charge is ignited by the igniting tube, and the piston is driven forward with a very powerful impulse, the ordinary cycle at once coming into operation. This method of starting is so powerful that an engine can be started with partial load on, and practically dispenses with the use of fast and loose pulleys or friction clutch.

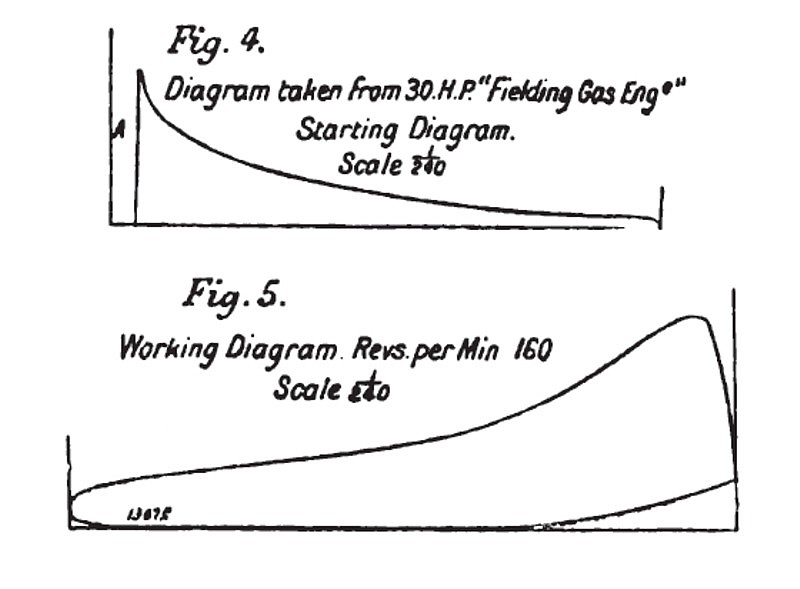

The diagrams Figs. 4 and 5 show how powerful an impulse is given at starting. |

|

1893 Fielding and Platt, Gas Engine

1893 Fielding and Platt, Gas Engine

1893 Fielding and Platt, Gas Engine (drawings)

1893 Fielding and Platt, Gas Engine (drawings)

1893 Fielding and Platt, Gas Engine (power diagrams)

1893 Fielding and Platt, Gas Engine (power diagrams)

|

|