|

Title: |

1906 Article-Fitchburg Machine Works, Lo-Swing Lathe |

|

Source: |

Page's Engineering Weekly, 05 Jan 1906, pgs 24-25 |

|

Insert Date: |

6/5/2012 8:20:23 PM |

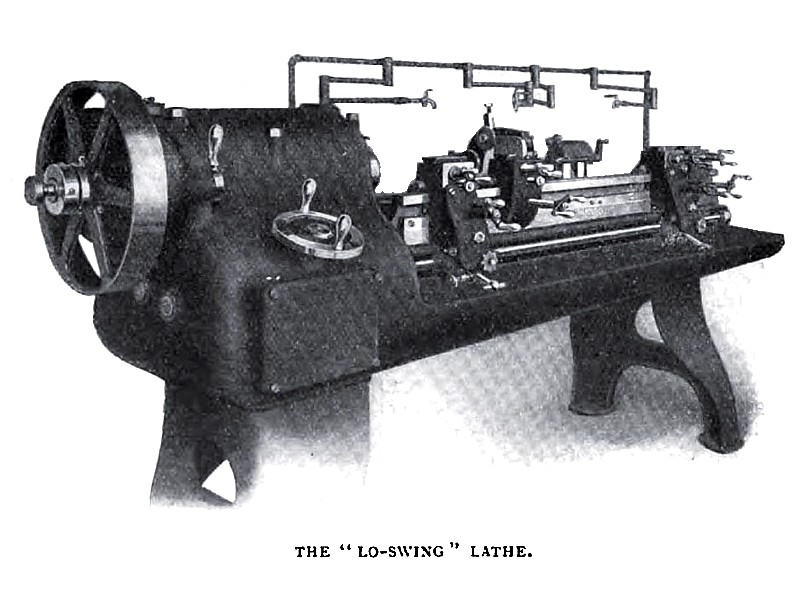

"LO-SWING" LATHE BY THE FITCHBURG MACHINE WORKS, FITCHBURG, MASS.

The latest product of the Fitchburg Machine Works, Fitchburg, Mass., is a single purpose lathe, for doing work on bar stock of the class that must be done between centres. Its two most distinctive features are, first, a very low swing, just enough to clear a 3+-in. bar, hence its name, "Lo-swing lathe "; and second, single-slide tool carriages, several of which may be simultaneously employed. The low swing gives firm control with great accuracy and speed of turning, and the advantage resulting from the use of small carriages is that more than one tool may be cutting at a time, the result obtained being greater output per man and per square foot of floor space occupied.

The cutting tool is a piece of high speed steel machined to fit closely a 5/8-in. by 3/4-in. hole in the tool holder. The cutting end projects just far enough beyond the tool holder to meet the requirements of the work. This cutter is caused to slide in and out of its holder by an adjusting screw conveniently operated by handle.

A convenient scheme is provided for quickly binding or releasing the tool holder so that the lathe hand may

rapidly change from one tool holder to any other, either for sharpening purposes or to insert some other form of tool that may be required by the work.

The tool carriage differs so much from the standard form that the use of the same name seems misleading, but although the name carriage is used, it will be understood in this instance to mean practically a single block of metal fitted to slide on a rectangular guide rail, and to carry a casting tool as close to the guide rail as possible; the guiding rail and sliding block being so formed that the cutting strains are squarely borne by the guiding rail. The absolute firmness of a sliding block of this kind, in which the metal is subject to a compression strain only, will be readily understood.

In the Lo-swing two kinds of carriages are used. One is provided with gears for power feed, and the other is without power feed gears; both are provided with handles for traverse by hand; also a connecting bar by which the carriages without feed may be fed in connection with the power-feed carriages.

The advantage of the carriage is not only in its being lighter, more convenient and more stable, but its width being only five inches instead of the usual two feet gives an opportunity to bring into simultaneous operation a number of tools on nearly all work over, say, eight inches long, the regular machine being furnished with four carriages tied together in pairs, two of which may feed in one direction, while the other two are feeding in the opposite direction, or all may travel in the same direction, and any or all may run back past the tailstock without moving the tailstock. The rolls used in both the follower and fixed rests are of large diameter, making the high speed practicable even on slender work. The main frame or bed of the machine is a single casting, which forms the guide rail on which the carriages slide, the drainage pan for chips and oil and the casing for enclosing spindle and gears.

The headstock is a part of the bed casting and is provided with the necessary gears for obtaining seven changes of speed. The gears and clutches for changing speed run in a shallow basin in which the lower edges are immersed in oil. The pulley for receiving a 3-in. belt is 18 in. in diameter, and runs at a constant speed of 560 revolutions. The spindle speeds range from 560 down to 50.

The proportions of gearing and all the running parts of the head have been made with special regard for the requirements of high speed steel. The spindle nose is very unlike the standard type. It only carries the centre point and a driver for the dog. The power feed for carriages is varied by hand-wheel on front of the head, any feed being instantly available.

The pump for oil for cutting tools is in the head end of the machine and gets its power from the main pulley, hence it does not require separate bolt. It takes the oil from the reservoir under the head, and delivers it to the cutting tools, after which the oil flows back to the reservoir. The machine may be belted to a constant speed motor placed on the floor or to a countershaft overhead. |

|

1906 Article-Fitchburg Machine Works, Lo-Swing Lathe

1906 Article-Fitchburg Machine Works, Lo-Swing Lathe

|

|