|

Title: |

1858 Article - Hub turning machine and hub mortising machine |

|

Source: |

22 May 1858 issue of Scientific American |

|

Insert Date: |

10/22/2003 11:14:16 PM |

What follows is the complete text of the articles.

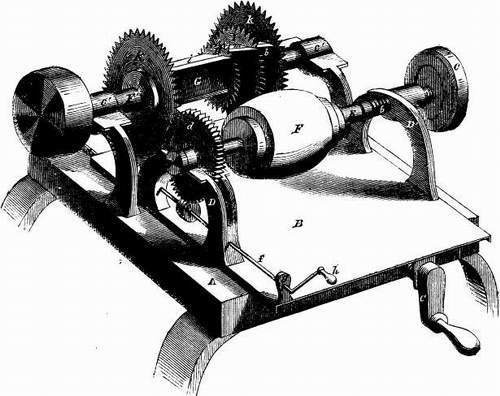

IMPROVED MACHINE FOR TURNING HUBS

Of late, inventors have turned much of their attention to the production of new, and the improvement of old, carriage machinery, or combinations of mechanism, for the production of the several parts of carriages. The most important parts of a vehicle are, undoubtedly, the wheels; and on the soundness and accuracy of the hubs the safety of the carriage or cart depends.

Lovett Eames, of Kalamazoo, Mich., has invented a machine for turning the hubs of vehicles, which will admit of them being made any size, and perfectly in proportion, by simple and convenient mechanism. The machine is represented in our engraving, and its construction and operation we will now describe.

A is a bed, mounted on a suitable frame, and en it there slides a bed plate, B, upon the ways, a. The bed plate, B, is moved back and forth by the handle and screw, C. From B there rise two supports, D and D', carrying journals, in one of which, D, there is a cog wheel, d, that is rotated by the worm, e, upon se shaft, f, passing through the standard, g, by the handle, h. The hub, or block F', from which it is to be cut, is placed between the axle of d and E, that has upon it a screw, b, passing through a nut journal in D, operated by a hand wheel, c, that brings the hub into proper position, and holds it there.

From A there also rise two supports, having journals, c', upon them; through these passes the axle, F', carrying the saws, K H I k, for grooving and allowing the cutters to shape the hub in the proper manner. These cutters are placed on squares, G, between the saws, like the cutters of a planing machine, and are indicated by i m b.

The operation is very simple. A rapid motion being given to the cutters and saws from any prime mover, the hub or block is fed up to them by means of the handle, C, and the hub is rotated before them, so that it shall be cut perfectly round, by the handle, h, before described. A patent on this machine is applied for.

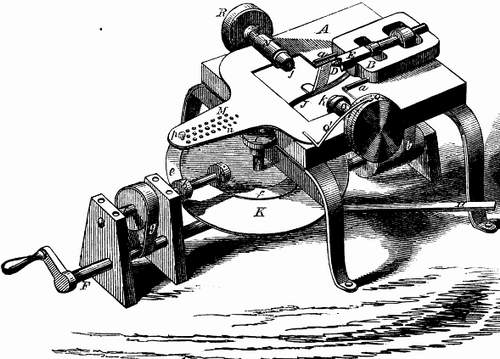

EAMES' HUB MORTISING MACHINE.

The improvements which constitute the invention in this mortiser are, the peculiar methods employed of giving the feed motion to the cutters, and other points, that will be seen as we proceed in our description. It is a supplemental machine to the above, and can either be used as such or by itself, the hubs being turned by any other machine. It was patented this week, and the claim will be found on another page.

A is a bed plate, mounted on any proper frame, and carrying a cutter frame, B, which slides upon the ways, a. In this frame, B, is a hollow cutting mandrel, E, in which there rotates a boring tool, D, turned ty the belt, b, from the drum on the shaft of the crank, F. The hub is placed between the chucks, j and k, that rest on axles passing through journals, N and 0. The hub is fixed tight and moved round by the wheels, R Q - Q being a stop wheel, having a spring stop, Q', fitting into holes on its periphery, and thus regulating the distance apart that the mortises are to be, to accommodate the proper number of spokes. These chucks, wheels, and journals are placed on a movable plate, M, that moves to the right and left, and by a pin, p, passing through holes, n, in M, into corresponding holes in A, the hub is presented at a proper angle to the tool, to give the required ?dish' to the wheel when the spokes are driven firmly in.

The feed motion is given to the tool in an ingenious way; to B there is secured a link, J, the other end of which is connected with a crank wheel, I, upon an upright axle, G, to the bottom of which there is also a large disk, K. On this disk there are two semicircular raised pieces, e and f, in the position shown, and on or over these move the rollers, Is i, upon the shaft, L; this shaft is rotated by the band, g, from the main crank shaft, F. As it is necessary to give a slow feed motion when the hub is being cut, the roller, Is, first passes over e, and by friction gives motion to K, which draws the cutter or tool into the wood and the amount of friction and consequent power of the feed in hard or soft wood is regulated by the lever, H, into one end of which the axle, G, is stepped, so that by pressing with the foot upon the other, the plate, K, is raised, and the ways, e and f, brought into closer contact with the respective rollers. The tool having cut the required depth, the gigging back must be quick, so the way, e, ceases, and i passes on to f, and that being nearer the center of K than e, gigs back the tool very quickly while the hub is being turned to the next spot to be mortised. A belt pulley may be substituted for the crank, F, when the machine is operated by power.

The inventor will give any further information concerning either of the above inventions upon being addressed at Kalamazoo, Mich.

|

|

Eames' Machine for Turning Hubs

Eames' Machine for Turning Hubs

Eames' Hub Mortising Machine

Eames' Hub Mortising Machine

|

|