|

Title: |

1881 Article-Hewes & Phillips Iron Works, Metal Shaper & Gear Cutting Machine |

|

Source: |

American Machinist 01 Jan 1881 pg 2 |

|

Insert Date: |

4/9/2012 9:14:53 PM |

New Shaping Machine, and Gear Cutting Machine.

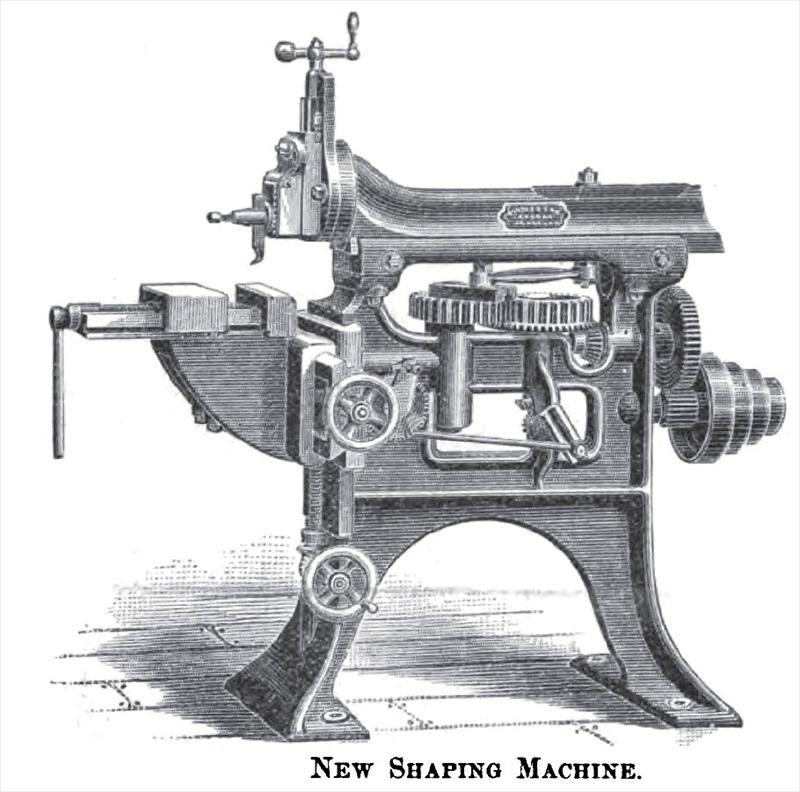

One engraving shown herewith represents an improved shaping machine which possesses some new and meritorious features, as will be understood by an inspection of the engraving and the following description:

The machine is of strong and substantial design. The stanchion, which takes the entire thrust of the ram, and upon which the accuracy of the machine so largely depends, is strong and sufficiently well braced to meet all requirements.

A common error into which many tool builders have fallen is, that of striving to make a shaper which will perform all the functions of a planer. To secure this result the length of the stroke has been gradually increased, until the efficiency and

expeditiously as well as a constant assistant to the vise hand. These ends have been kept in view by the designer of the shaper shown in the engraving. It has a table and vise, also a stroke of 9", and a cross motion of 18". The table can be elevated or lowered 9". The tool box has a vertical motion of 6". The return stroke has three times the velocity of the forward stroke, this motion being secured by a pair of elliptical gears. The stroke may be altered from 0 to 9" by means of a slotted crank cast upon the elliptical gear. The cross feed is automatic, and is changed from fine to coarse by a variable crank motion. All screws are made of steel and all surfaces broad and scraped to a perfect bearing. The lost motion in the fiddle and cross-head is taken up by means of taper wedges, with a screw adjustment. Full set of wrenches, counter shaft, hangers and pulleys, are furnished with each machine. The largest size of this style machine has a stroke of 16", and is especially calculated for railroad shops and other heavy work.

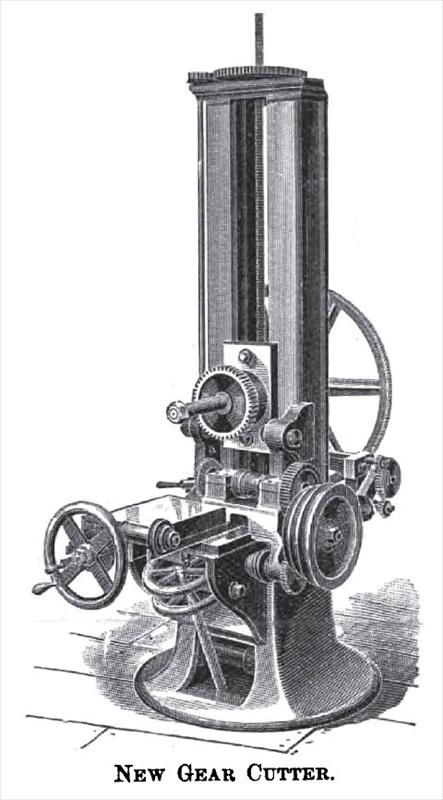

A gear-cutting machine is shown by the other engraving, The manufacturers of this machine have entirely remodeled their gear cutters, as made some years ago, and to meet the wants of establishments requiring such tools. They are now making two sizes of the improved machines, the smallest one having a capacity to cut any gear from one inch to 48'' in diameter and a 5" face, and the largest one from 1" to 84" diameter and a 10" face. The cutter carriage, as will be observed, is swung from a fulcrum upon the stanchion, and can be tilted by means of an adjustable screw underneath to cut gears of any required angle. The carriage also has an automatic friction feed with three changes of speed, secured by grooved cone pulleys. An automatic stop motion is attached, which is so arranged as to give a feed of any required length from 0 to the full capacity of the machine.

The worm-dividing wheel is laid out with mathematical accuracy by a standard dividing machine, and is made in halves. In the process of finishing with a worm milling tool the relative position of the sections is repeatedly changed, and the teeth remilled after each change, until all inaccuracies in the pitch are practically eliminated, thus securing the greatest perfection in this vital feature of a gear cutter. The screws and spindles are all made of best cast steel. All journals are large and well fitted, and sliding surfaces broad and scraped to a perfect bearing. A proper complement of change gears, to cut a large range of pitches, is furnished with each machine; also counter shaft, pulleys and hangers, also a full set of case-hardened wrenches. A tightener with weight is provided to keep a constant and proper tension of belt.

These machines are made by the Hewes & Phillips Iron Works, Newark, N. J. E. P. Bullard, Agent, 14 Dey street, N. Y. |

|

1881 Hewes & Phillips Iron Works, Gear Cutting Machine

1881 Hewes & Phillips Iron Works, Gear Cutting Machine

1881 Hewes & Phillips Iron Works, Metal Shaper

1881 Hewes & Phillips Iron Works, Metal Shaper

|

|