|

Title: |

1906 Article-L. Robbins, 16 inch Patternmakers Lathe |

|

Source: |

Woodcraft, Apr 1906 pg 31 |

|

Insert Date: |

2/12/2012 1:01:09 PM |

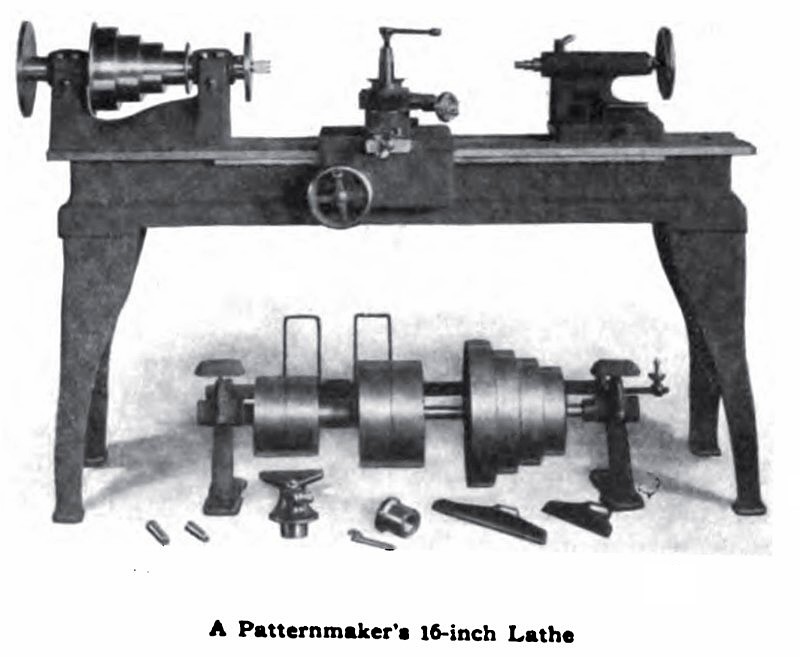

A 16-inch Lathe

This lathe is a new model, noticeable for its fine lines and good proportions. It is built from an entirely new set of patterns, much heavier than the old lathe of this make, and embodies the latest improvements. The head spindle is of high carbon crucible steel and runs in ring oiling phosphor bronze bearings, an eminently satisfactory construction for high speed tools. It has a large outer faceplate and tripod rest for turning larger work than will swing over the bed. The head cone is turned on the inside to secure a perfect balance and has four sections for 2¼-inch belt, giving with the two speed countershaft, eight spindle speeds arranged in a regular gradation. These give a complete range of speeds for all sizes and classes of work. For convenience in using twist drills, chucks, etc., the center holes in both head and tail spindles are made to a No. 3 Morse standard taper.

The carriage has hand feed the entire length of bed to which it is gibbed on both front and back sides. The compound tool block is graduated in degrees and interchanges instantly with a holder carrying the tool rests for hand turning. The tail stock sets over for turning taper on work between the centers and is of the latest pattern, allowing the compound to be used when swiveled parallel to the ways. The countershaft is generally considered of minor importance, but in the present instance has had special attention. The designer of this lathe believes it advisable to discard the friction countershaft for high speed work and has been successful in contriving a simple yet satisfactory two-speed arrangement of tight and loose pulleys. Two pairs of self-oiling tight and loose pulleys of different sizes are combined with a patented shifter mechanism whereby one shipper only is required for both belts. The shipper motion is identical with that in a friction countershaft but has not the adjustment difficulties and wear usually found attendant upon high speeds. The new device has been found to possess easy starting qualities. The hanger boxes are self-oiling. The counter-cone is of large diameter, carefully balanced and gives a powerful drive.

Every lathe is sent out with a two-speed countershaft, tripod rest, three tool rests, pair of wood centers, pair of pointer centers, two face-plates, screw-plate, and the necessary wrenches. The lathes are belted, critically examined and tested at high speed before shipment. They will swing work 16¾ inches diameter over the bed, 12¼ inches diameter over the carriage and on a 6-foot bed will take 39 inches between the centers. The weight with 6-foot bed is 1040 pounds. This machine is built by L. Robbins, Worcester, Mass. |

|

1906 Article-L. Robbins, 16 inch Patternmakers Lathe

1906 Article-L. Robbins, 16 inch Patternmakers Lathe

|

|