|

Title: |

1892 Article-Putnam Machine Co., Universal Milling Machine |

|

Source: |

American Machinist 25 Feb 1892 pgs 3 & 4 |

|

Insert Date: |

12/26/2011 7:24:24 PM |

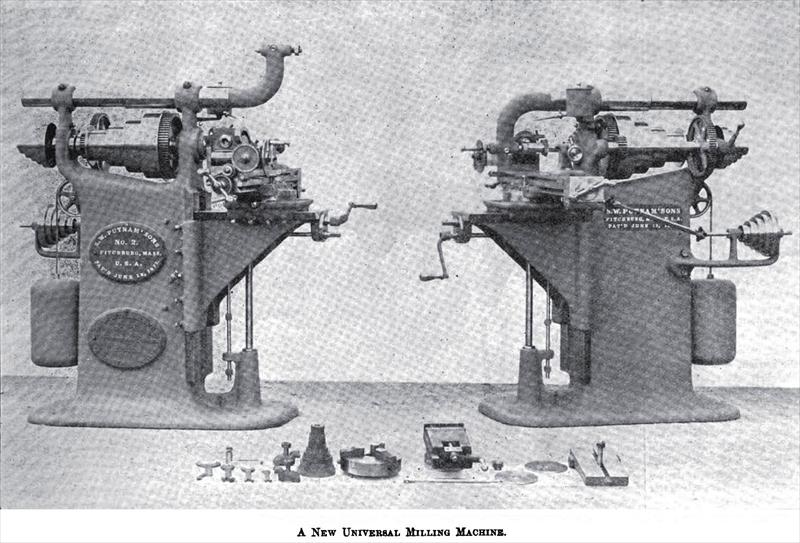

New Universal Milling Machine — It has been known for some time among those who keep track of shop matters, that the Putnam Machine Company, of Fitchburg, Mass., were getting ready to bring out a universal milling machine in which the intention was to adhere closely to the general features of what has now become the recognized standard form of such machines, while at the same time some new features were being introduced. We present herewith two perspective and some detail views of this machine, by which it will be seen that the most striking new feature is that of counterbalancing the knee. The method of doing this will be clearly perceived by an inspection of Fig. 2.

Two sheaves are placed as high as possible in the frame, over which a chain or steel cable passes to a weight in the back of the machine. The weight is sufficient to balance the knee within a small fraction of its weight, and its effect is to lessen the labor of moving the knee, and to reduce the wear upon the mechanism by which this is accomplished.

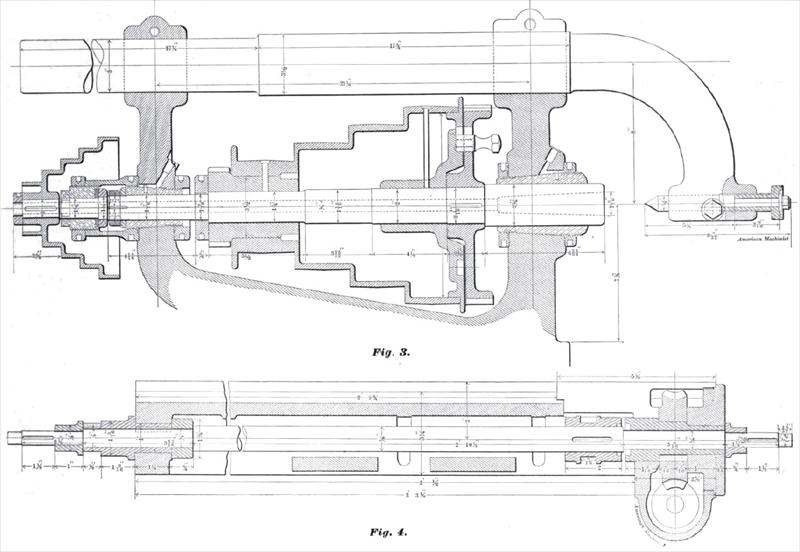

It also makes the handling of the machine more "sensitive" than it otherwise would be, i. e., since the knee requires much less force to raise it to a cut, the cut is much more readily felt, and the action and condition of the cutter with respect to its truth and sharpness is more readily perceived. Fig. 3 is a section of the head showing the arrangement of the spindle and bearings. It will be noticed that the bearings are entirely plain, that the thrust is taken on the rear one, allowing for expansion through the main bearing, the boxes being plain cones outside, which are fitted to conical seats in the frame and adjusted by threaded rings. They are of composition and are easily renewable. The spindle is hollow throughout, and has the same taper as the Brown & Sharpe machine, the taper in the index spindle being similar, so that the arbors may be-used in either.

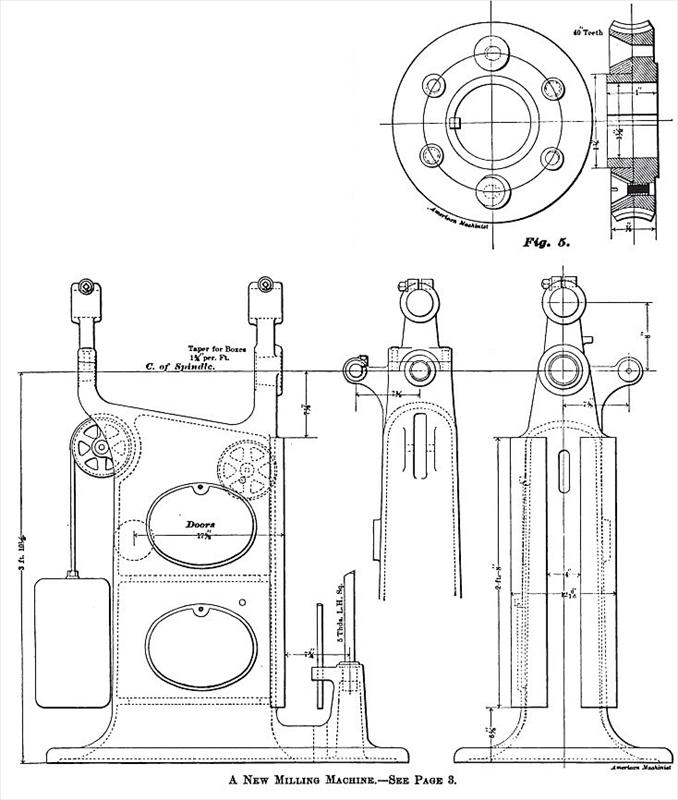

The machine is back-geared to secure a great range of speeds, the proportions being such that regular gradations are obtained from the fastest to the slowest, and any cutter likely to be used in the machine can be driven at its proper speed.

There are five changes of feed, and the feed screw is driven by worm gearing, so arranged as to leave the top of the platen clear, so that work may extend out over it as far as may be desired without blocking. Balanced handles are fitted to each end of the feed screw, so that it can be handled from either end, as most convenient. Fig. 4 is a section of platen showing the arrangement. Fig. 5 shows the arrangement of the indexing worm-wheel, which is made in two parts, one of which can be turned upon the other by the taper screws shown, so as to take up all lost revolution, after which it can be clamped by the other screws. The base upon which the platen rests is circular and graduated upon the outer face.

The knee has a vertical movement of 17" upon the column, and the saddle moves 9½" upon the knee parallel to the spindle. Work 10" diameter and 20" long can be swung upon the centers and all the usual operations performed upon it, there being three index plates and gears for obtaining any desired spiral, either right or left hand. The index head can be set at any angle from 5° below the horizontal to the vertical. The machine is provided with all needed conveniences — 6" universal chuck, vise with jaws 5" wide, 1" deep and opening 2 3/8", wrenches, hand wheels, etc. The countershaft has two friction pulleys for 4½" belt, and should make 100 revolutions per minute. The floor space required is 50"x55", and the weight 2,850 pounds. |

|

1892 Putnam Machine Co., Universal Milling Machine

1892 Putnam Machine Co., Universal Milling Machine

1892 Putnam Machine Co., Universal Milling Machine Spindle

1892 Putnam Machine Co., Universal Milling Machine Spindle

1892 Putnam Machine Co., Universal Milling Machine Base

1892 Putnam Machine Co., Universal Milling Machine Base

|

|