|

Title: |

1892 Article-E. W. Bliss Co., Toggle Joint Drawing Presses |

|

Source: |

American Machinist 18 Feb 1892 pgs 1 & 2 |

|

Insert Date: |

12/23/2011 8:38:39 PM |

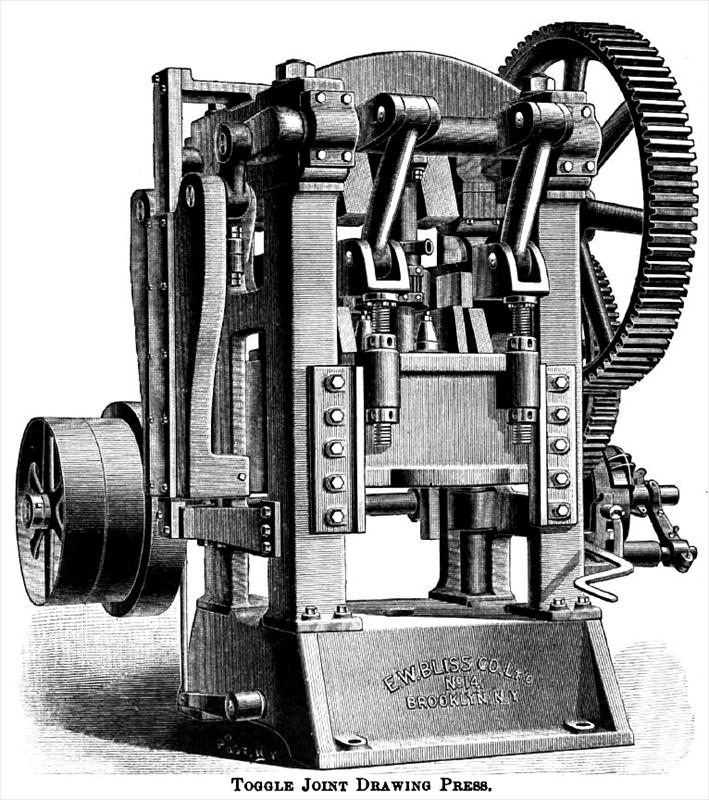

Toggle Joint Drawing Presses — In our issue of October 23, 1890, we illustrated a large drawing press which was driven by an engine attached, and in which there were some new features of construction, especially in the blank holder mechanism, the blank holder being made to "dwell" and exert its pressure upon the blank during the drawing operation, by means of a system of toggle joints, worked by connections attached primarily to a heavy sliding block at the side of the machine, one of the offices of this block being to counterbalance the weight of the blank holder and the plunger.

By means of this mechanism the blank holder is made to exert its pressure steadily, and without imposing any strain worth speaking of upon the working parts of the machine during the dwell—an action which not only saves much power, but also much wear and tear of the machine and expense for repairs. By reference to our detailed engravings, published in the issue referred to, the action of this mechanism will be readily understood.

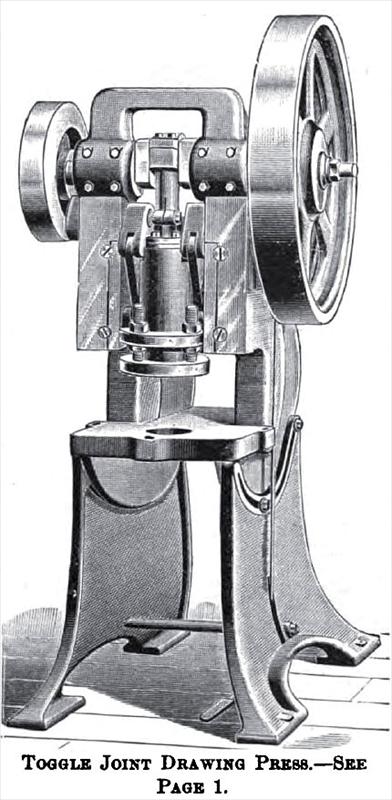

The present illustrations show the largest belt driven, and the smallest machine (see page 2) built to employ this principle. In the larger one the motion is controlled by means of a friction clutch, which, while it acts in such a way as to effectually relieve the machine of injurious shock, at the same time acts promptly and enables the motion of the slide to be arrested at any point, and, in short, gives the operator full control of the machine.

It will be noticed that the sides of the frame are straight, and the tensile stress imposed during the operation of drawing is taken by four 4¼" steel bolts which pass up through the columns from the bed to the upper cross-piece.

This machine is adapted to drawing the largest and heaviest articles made of tinplate and nearly everything made of black iron or steel in the manufacture of enameled iron ware. It is also adapted to such work as is done in drawing the heads of kitchen and bath boiler heads, soda fountain cylinders, the smaller sizes of sinks, heavy brass and copper goods, and all work of similar character.

The width between the uprights is 46"; distance from bed to face of blank holder when stroke is down and adjustment up, 20"; distance from bed to face of plunger when stroke is down and adjustment up, 22"; stroke of blank holder, 15"; stroke of drawing punch, 22"; adjustment of blank holder 8"; and of the punch the same. The ratio of the gearing is 1 to 38½, and the machine is designed to work at a speed of 7 strokes per minute. The extreme height to the top of the gear is 168", and the floor space occupied, 104x157". The largest blank which can be drawn is 44" diameter, and the largest punch which can be used is 31" diameter.

The smaller press is adapted to all such work as is done in forming blacking boxes, baking powder can tops, lamp burners, parts of lanterns, gas fixtures, cartridge shells, etc. The toggle joints in this case are operated by cams, which are placed on the crankshaft, the pressure which is placed upon the blank, and maintained during the drawing, imposing comparatively very slight stress upon the cams. The blank holder in both of these machines can be adjusted to secure an even pressure upon the blank all around, without the necessity for packing the die, screws being provided for that purpose. The crankshafts are of forged steel, with the cranks slotted out from the solid metal.

The machines are built by the E. W. Bliss Company, Brooklyn, N. Y. |

|

1892 E. W. Bliss Co., Toggle Joint Drawing Press

1892 E. W. Bliss Co., Toggle Joint Drawing Press

1892 E. W. Bliss Co., Toggle Joint Drawing Press

1892 E. W. Bliss Co., Toggle Joint Drawing Press

|

|