|

Title: |

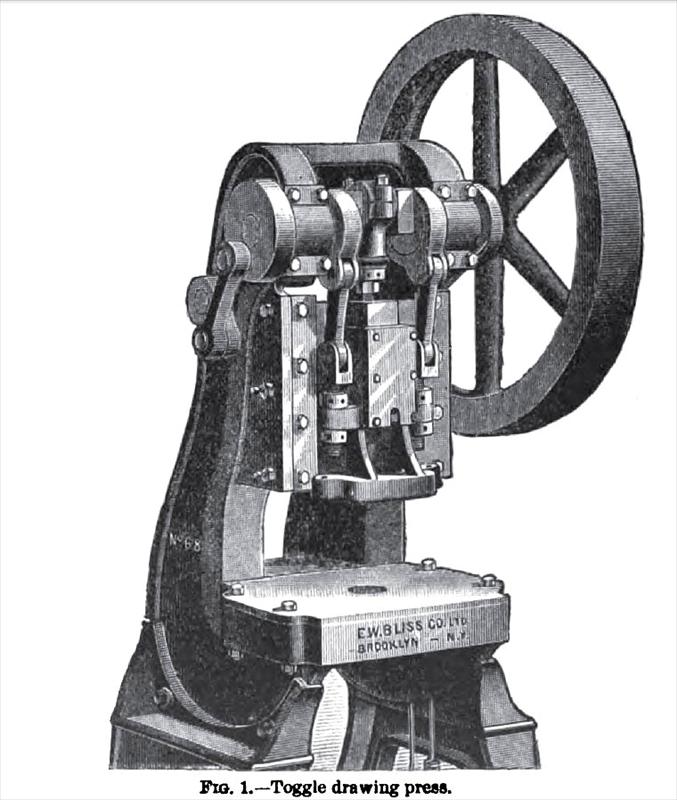

1895 Article-E. W. Bliss Co., #68 Toggle Drawing Press |

|

Source: |

Modern Mechanism 1895 pgs 665-666 |

|

Insert Date: |

12/5/2011 4:38:26 PM |

PRESSES, DRAWING. Sheet Metal — Toggle Drawing Presses — The most important recent improvement in drawing presses is the perfecting of an arrangement for operating the blank-holder by means of toggles, which entirely dispenses with cams of any description. Two rock shafts are placed across the back and front of the frame, to which the blank-holder yokes are connected by toggle links. These rock shafts are operated from a crank on the outer end of the main shaft, by a peculiar system of link work, which imparts, through the blank-bolder, a much more uniform pressure to the blank than can be maintained in cam drawing presses. The strain arising from the

pressure put upon the blank is transferred through the straightened toggles directly to the frame of the press, instead of falling on the main shaft, thus relieving entirely the bearings from all friction and wear due to the blank holding. Better and smoother work, with fewer wasters, greater durability, and less consumption of power, are the principal advantages gained through this toggle movement. n presses of this type, made by the E. W. Bliss Co., of Brooklyn, N. Y., the main frame of the usual sizes is made of a single casting. The main shaft is of forged steel, with a crank slotted out to operate the plunger. This plunger is guided on the inside of the blank-holder slide and connected to the crank by a pitman with steel adjusting screw, provided with right and left-hand ratchet collars for quickly adjusting same. The adjustment of the blank-holder is made by means of four steel screws. In the larger sizes, power is communicated to the powerful friction clutch, which, in connection with the automatic brake, places the movements of the press entirely under the control of the operator, so that the press can be stopped and started instantly at any point of the stroke.

Fig. 1 shows one of the smaller sizes of press made by the E. W. Bliss Co. This press is adapted for operating double-action dies in the manufacture of brass, tin, and other sheet-metal shells not exceeding 8½ in. in diameter or l½ in. in depth. This includes a large variety of lamp and burner work, tin boxes and covers.

Manufacturers of metal goods of various kinds have discovered that many articles which have heretofore been produced by casting them, or by forging, can be made by the process of cold drawing, provided the proper machine is constructed, and the tools used with it are made with due regard to the behavior of the metal worked in the drawing press. Many comparatively thin and light articles, which have heretofore been cast, are now being drawn out of sheet metal, and the drawing process is found to have so many advantages peculiar to itself that the limits within which it is applied are constantly being extended. |

|

1895 E. W. Bliss Co., #68 Toggle Drawing Press

1895 E. W. Bliss Co., #68 Toggle Drawing Press

|

|