Image

Manufactured By:

J. A. Fay & Co.

Keene, NH; South Keene, NH; Worcester, MA; Norwich, CT; Cincinnati, OH

|

|

|

Title: |

1895 Article-J. A. Fay & Co., Endless-Bed Wood Surface Planer |

|

Source: |

Modern Mechanism 1895 pgs 631-632 |

|

Insert Date: |

12/4/2011 8:51:23 PM |

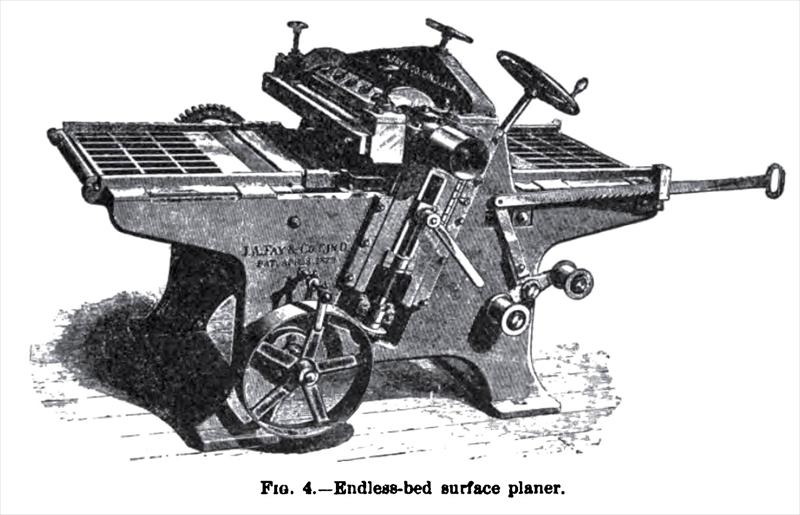

The Fay Endless-bed Surface Planer.—A method of feeding the material in wood planers, differing from the hand, carriage or platen, and pressure-roll methods, is by an endless bed, as shown in Fig. 4. It is especially desirable for green, wet, or icy lumber: and the demand for this type is constantly increasing in this country. There is an endless apron or bed of slats driven by heavy gearing, and remaining in a fixed position at all times. The lags or strips composing it are of cast-iron, but the bearings on the ways are plated with steel. The cylinder is of large diameter, lipped with steel, and carries three knives, and pulleys for two belts. It runs in self-oiling bearings in a cylinder frame which is raised and lowered by a hand wheel. A weighted pressure oar is placed before the cut, as is also a pressure roller supplied with springs which give an elastic tension, that is controlled by a screw and hand wheel, so as to give any desired pressure. The cylinder frame carrying the cutters is gibbed to the sides. The cylinder and pressure bar adjusts simultaneously to the thickness of cut, by a single movement of the hand wheel. The feed is started and stopped by a binding lever. A development of this machine, of much heavier build, for planing-mills, bridgework, etc., has a stationary cylinder so that the countershaft may be either on the floor or overhead, as desired. There is a chip-breaker for holding the fibre of the wood during the process of cutting, and a pressure roller in front weighted with folding levers so arranged that either end will work independently of the other, which is desirable on unevenly sawed lumber. This allows the rollers to adjust to the different thicknesses of the lumber without unduly straining any of the parts of the machine.

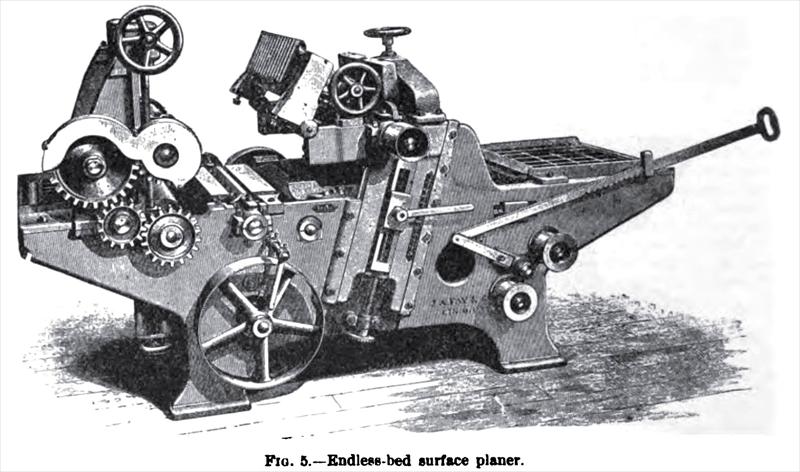

The machine shown in Fig. 5 has the line of the bed in a fixed position, the upper and the lower cylinders, and the pressure bar over the latter, adjusting simultaneously to suit the thickness of the timber. The upper cylinder carries four and the lower one three knives, and either can be raised or lowered when running. The pressure bar over the lower cylinder is hinged, and can be swung back out of the way to give free access to the cutters. "There is a set of heavy delivery rollers after the lower cylinder, driven by expansion gearing, and feeding the lumber away from the machine, thus relieving the strain on the travelling bed in feeding heavy lumber. There are two speeds of feed, 40 and 60 ft. per minute. The feed rollers are broken in their length, so that either one wide board or two narrow ones of unequal thickness may be planed at once. The cylinders have chip-breakers. A uniform elastic pressure may be maintained by pressure springs. The pressure bars before t he cut are sectional, one for each divided roller, and are raised simultaneously with the upper cylinder. |

|

1895 J. A. Fay & Co., Endless-Bed Wood Surface Planer

1895 J. A. Fay & Co., Endless-Bed Wood Surface Planer

1895 J. A. Fay & Co., Endless-Bed Wood Surface Planer

1895 J. A. Fay & Co., Endless-Bed Wood Surface Planer

|

|

|

|