|

Title: |

1882 Article-Frey, Sheckler & Hoover, Emery Wheel Gummer for Circular Saws |

|

Source: |

Grimshaw on Saws 1882 pgs 186-187 |

|

Insert Date: |

12/2/2011 8:09:06 PM |

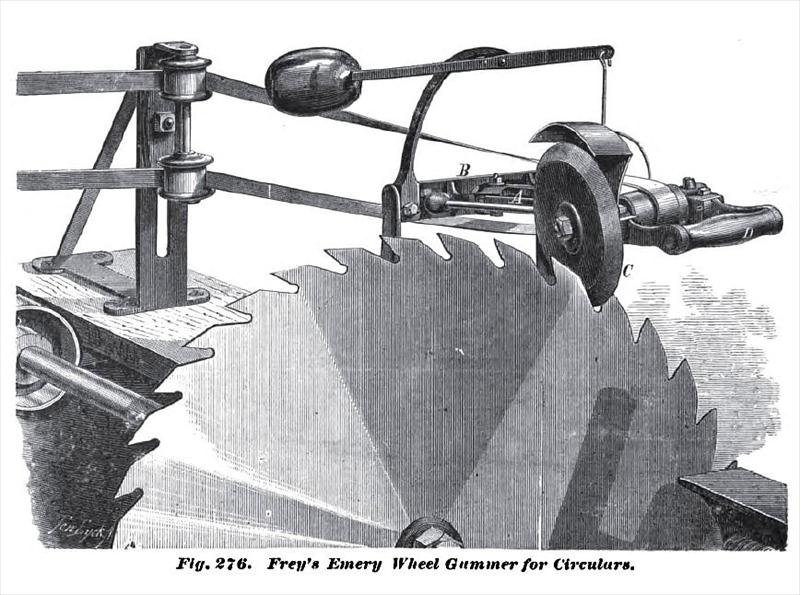

Frey's Gummer.—Fig. 276 illustrates an emery wheel gummer and grinder, as arranged for grinding or gumming the saw without removing it from its mandrel.

This device consists in an abrading wheel of emery or corundum, fixed on a shaft, set in a flexible frame and put in rapid motion.

By means of a handle it is easily controlled by the operator, and placed at any angle necessary to the saw or article to be filed or dressed. It is especially applicable to the gumming of saws, circular or upright, and the shaping or forming of molding bits, or similar tools.

The working portions of the machine are composed of a movable frame, A, which by a ball joint is hung on the main frame, B, so that the grinding wheel, C, has a universal movement, controllable by the handle, D. A still freer motion is afforded by a second joint on frame A, or the latter may be arranged by means of two movable slides so as to give a positive up-and-down or diagonal movement, as desired, also by two parallel rods hinged on main frame, B, by ball joints, placed on each side of flexible frame, A, and coupled to it immediately back of pulley. By this arrangement a direct parallel lateral movement is secured, and the wheel kept square to its work.

The lever and weight shown, serve to balance the frame and wheel, and make it easy for the operator to control the angle or position of the wheel.

Directions for Setting and Operating.—For a saw-mill run by a belt: Place the machine immediately behind the saw, upon a plank on the side where the teeth turn up, the shaft of the machine being directly over the saw in a line so that the emery wheel will form a right angle with it. The counter-shaft is placed on the back end of the plank, in a direct line with the driving pulley on the engine. The belt or cord is placed upon the small pulley of the machine, then around the small pulleys on the counter-shaft, turning at a right angle to the driving pulley.

The motion of the wheel should be 1500 to 2000 revolutions per minute, the lower side always turning from the operator.

The operator applies the wheel to the saw by means of the handle, when the parts so brought in contact with the emery wheel will be speedily abraded without injury to the saw.

When gumming saws, where the teeth are very blunt, do not attempt to do too much at once, but move from tooth to tooth, giving them time to cool, and then repeat the operation until the tooth is brought to the proper shape.

If the wheel is held to the saw too hard and too long, the saw is liable to blue and case-harden.

To use the machine on a direct acting-mill: The saw is generally taken off. The machine is placed on a frame or table, in such a position that it can be run from the engine or some other convenient shaft.

Mulay, drag, and crosscut saws can be dressed with equal facility.

If it is preferred to dress a circular saw on a direct acting mill, without taking it off the mandrel, a wheel with a crank is used to rotate the emery wheel by hand. The power required would be about the same as would run a common-sized grindstone.

Patent 134,425 |

|

1882 Frey, Sheckler & Hoover, Emery Wheel Gummer for Circular Saws

1882 Frey, Sheckler & Hoover, Emery Wheel Gummer for Circular Saws

|

|