|

Title: |

1909 Article-Crocker-Wheeler Electric Co., Electric Motors |

|

Source: |

Cyclopedia of Applied Electricity, 1909 pgs 426-431 |

|

Insert Date: |

11/2/2011 7:01:07 PM |

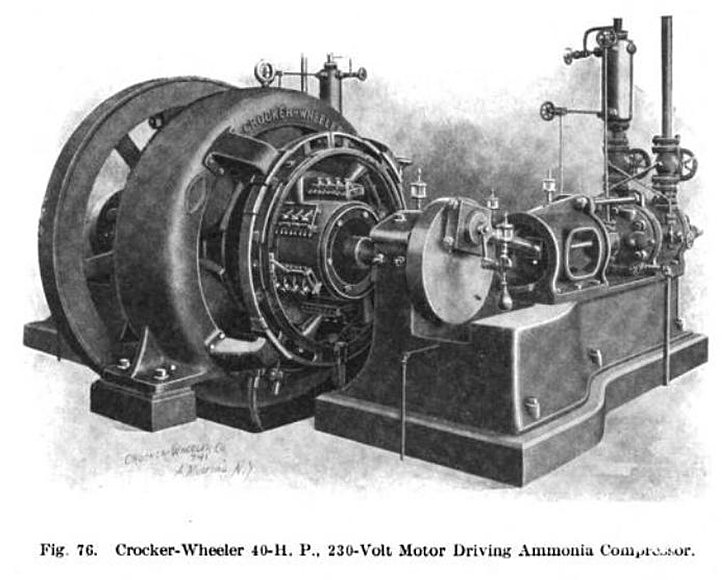

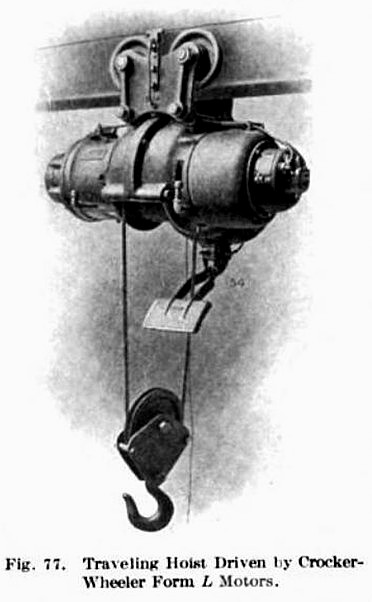

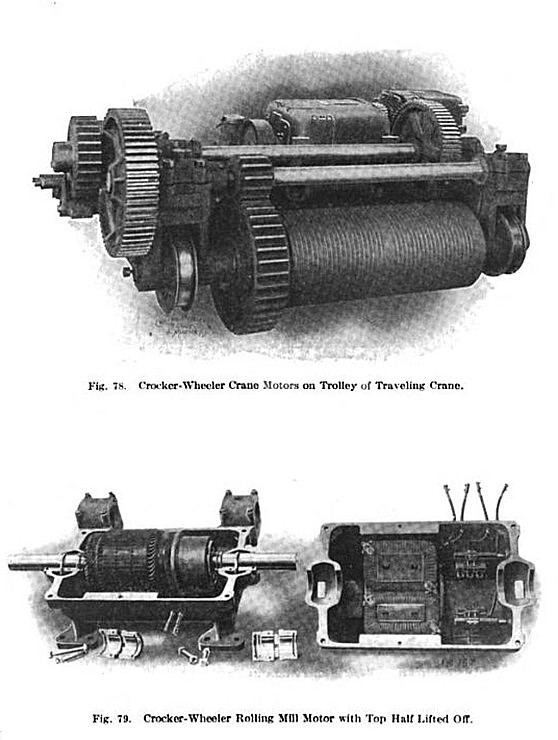

Crocker-Wheeler Company — The larger constant-speed motors running between 870 and 360 R. P. M. and varying from 50- to 275 H.P. capacity are obtained by this company by using their form D frames, shown in Fig. 23. They can be wound so as to run on 110, 115, 220, 230, or 500 volts. Their form I machines, shown in Fig. 24, give them shunt motors from 2½ to 45 H. P. at any of the above five voltages, the speeds falling between 1,650 and 330 R. P. M. This type of frame can be shunt wound, series wound, or compounded to any degree, as well as furnishing a line of field-weakening adjustable-speed motors giving a speed range of 3 to 1. It also can be arranged for floor, side wall, or ceiling mounting and with vertical shaft. By adding proper covers to the open type it becomes en closed or semi-enclosed, the latter either grid or gauze. Enclosed motors are particularly adapted to operate in flour mills, wood working shops, boiler rooms, machine shops, etc., where the air is continually filled with fine particles. Being almost air tight, they are larger frame for a given output than open, ventilated motors; but with proper windings and frame they may be of practically the same efficiency-as the open types. They are not very well adapted for continuous running, but do admirably for intermittent service. This company brings out a line of slow-speed, constant-speed, direct connected motors having no shafts of their own. A motor of this line is intended to be keyed directly onto the shaft of the machine it is to drive, as shown in Fig. 76. They are designed for 220- to 230-volt circuits, ranging from 28 to 450 H. P. The highest speed is 350 and the lowest 83. These low speeds are possible by increasing the number of poles, they being from 6 to 12. Slow-speed motors have a smaller power output for a given weight than the high-speed types. This does not mean that their efficiency is lower, but that for a given horse-power rating, the slow-speed motor is the heavier and the larger. From this it follows that its cost per horse-power is greater. On the other hand, the slow-speed type runs cooler, has better mechanical construction, and stands long, continued overloads much better. For the smaller sizes, this company uses a 2pole motor called by them form L. They are made in sizes from 2V to 5 H. P. for operation on 115-, 230-, or 500-volt circuits and are suited for application to all sorts of light machinery. Fig. 77 shows one of the many uses. To supply the demand for traveling crane motors, this company has developed a line of motors shown in Fig. 78. They are made in

sizes from 1¾ to 65 H. P., operating on 220 or 500 volts. They are series-wound, compact, of strong and rugged construction, rectangular frame, and are protected against dirt and moisture by enclosing covers. Still another line of motors brought out by this company are their rolling-mill motors, shown in Fig. 79. These motors are built in 9 sizes from 7½ to 200 H. P. intermittent rating, at 220 volts. They are of enclosed construction with an octagonal steel crane. They are 4-pole series or compound wound. In the compound form the shunt is light, merely preventing the motor from doubling its speed if the load is removed. All insulation is fireproof and of great structural strength, allowing the motor to withstand outside roasting or internal heating from overloads. |

|

1909 Crocker-Wheeler Electric Co., 40 HP Electric Motor

1909 Crocker-Wheeler Electric Co., 40 HP Electric Motor

1909 Crocker-Wheeler Electric Co., Electric Hoist Motor

1909 Crocker-Wheeler Electric Co., Electric Hoist Motor

1909 Crocker-Wheeler Electric Co., Electric Motor1909 Crocker-Wheeler Electric Co., Crane & Rolling

1909 Crocker-Wheeler Electric Co., Electric Motor1909 Crocker-Wheeler Electric Co., Crane & Rolling

|

|