|

Title: |

1898 Article-Eddy Electric Mfg. Co., Electric Carriage Motor |

|

Source: |

The Electrical Engineer, 28 Jul 1898, page 83 |

|

Insert Date: |

10/23/2011 4:10:33 PM |

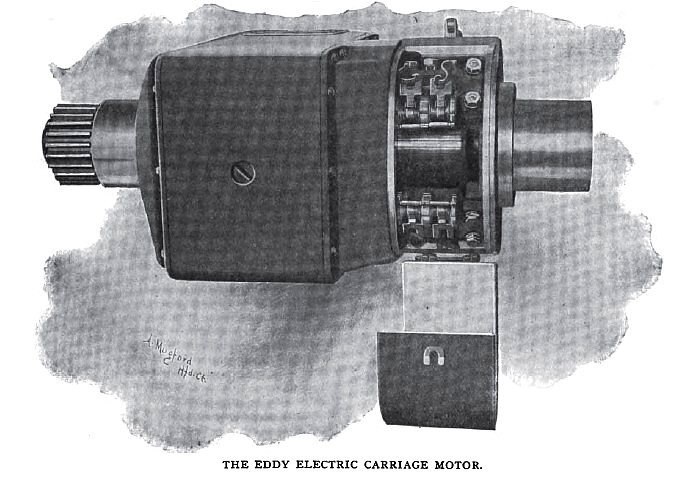

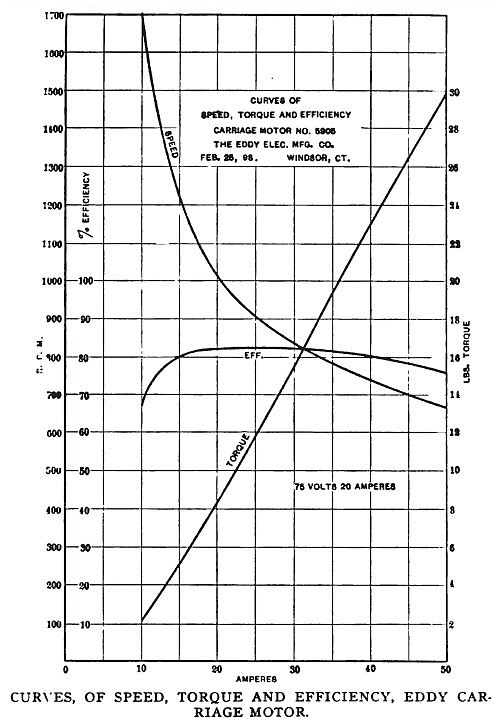

The Eddy Electric Carriage Motor — Thus far in spite of the limitations of the storage battery, the electric carriage has most successfully met the requirements. Careful investigation has shown that rarely does the daily distance traversed by the horses drawing city carriages, physicians' phaetons, hacks, hansoms, express and delivery wagons exceed twenty-five miles, and the average distance is much less than this. Without too great a weight of storage battery an electric carriage can easily accomplish this distance on one charge, and as it is clean, free from odor, practically noiseless, and easily handled, it has the advantage over other forms of propulsion, all of which lack one or more of these characteristics. It of course cannot, under existing conditions, pretend to be available for long distance work, but in its province is certainly a commercial success. In order to attain the successful results reached, the manufacturers of the American carriages have had to call on the makers of storage batteries and electric motors for apparatus to meet the peculiarly severe requirements of the service, and adapted to meet the requirements as above set forth. It is designed for an average current input of 20 amperes, and with this current and at 75 volts will run at 1,000 r. p. m. It will carry this current continuously without dangerous heating, and 40 amperes or 100 per cent, overload for twenty minutes without a rise in temperature exceeding 75 degrees Cent, above the air. It will also withstand loads up to 100 amperes for short periods. This capacity has been found to be ample for driving a two-seated carriage weighing about 1,800 pounds at a speed of about twelve miles an hour over good macadam roads, and is ample for ascending any hills likely to be encountered. For four-seated carriages two motors of this size are used. From 75 to 80 volts seems to be a convenient pressure at which to rate motors for this work, as this is about the minimum e. m. f. of discharge for a storage battery, at normal current, which may be charged from a no-volt circuit direct. The speed of 1,000 r. p. m. is sufficiently low to permit of convenient gearing with the axle of the carriage. In order to secure as light weight as possible, the motor is made with a field frame of Norway wrought iron forged to a consequently new types have had to be designed for this work.

The conditions under which the motor or motors of an electric vehicle operate are similar to those governing in street car work. The ratio, however, between maximum load and average load is much greater than with the trolley car, for every kind of roadbed may be found from sheet asphalt to thick mud, and any grade that a horse can climb must be ascended by the electric carriage. The motor must therefore have great capacity above that at which it is normally expected to run. For the economy of the stored energy the motor must have as high a commercial efficiency at the average load as possible, and this efficiency at heavy overloads must be maintained in order to minimize the strain on the battery. The efficiency of the motor at loads less than the average is not of great importance if the battery is properly proportioned for the work. Such loads occur when the carriage is on a declivity, and at these times the current drawn from the battery is very light. It is of course desirable that the motor shall be of as little weight and small dimensions as is permitted by the power and speed required. It must also above all things be "fool proof," that is, must be so constructed as to require no attention whatever and to withstand all kinds of abuse. The illustration shows a typical electric carriage motor rectangular shape and having two salient and two consequent poles. To this frame are bolted at either end cast aluminum casings, which support the rings for ball or roller bearings. The armature is mounted on a hollow shaft so that it may be suspended concentrically with the main axle of the conveyance. The armature winding consists of machine formed coils laid in slots cut in the surface of the laminated core. This form of construction is extremely light, but should only be used where the method of motor suspension supports the bearings directly and thus relieves the strain of the gears on the aluminum casings. The motor above described weighs complete but 128 pounds, a surprisingly low result when its power and efficiency are considered. The appended curves show the speed, torque and efficiency of one of these motors as found from an actual test with a Prony brake. The efficiency curve is the most interesting, perhaps, as upon it depends the range of operation of the carriage. It is noticed that the efficiency rises almost in proportion to the current until the normal load is reached, and from that point maintains a high reading up to 35 amperes or 75 per cent, overload, dropping so gradually after this that it is still remarkably high at 150 per cent, overload. As already stated, the maintenance of high efficiency from normal average load to heavy overloads is extremely desirable. It can only be obtained on such small machines by making exceptional efforts to reduce the internal resistance as low as possible. Extra care must be taken not only with the windings, but in all contacts. Especially is this true with the brushes and brush holders, and in the motor from which the above data was taken the holders were designed so that current was drawn from the self-feeding brushes without reliance at all on the sliding contact. Ball or roller bearings and low armature loss also contribute to the high efficiency attained. As the motor is suspended usually under the carriage frame it must be, of course, dust and water proof. It is subjected also to exceptionally severe jars and vibration, which tend to abrade and destroy insulation which under ordinary circumstances would be perfectly satisfactory. This brings before the manufacturer a problem, not easily solved even by those having had experience with railway work. The motor which has been illustrated and from which the data is taken is one manufactured by the Eddy Electric Mfg. Co., a concern that has had considerable experience with this class of work, and which has furnished motors of different types and sizes for the various electric carriage makers of the country. |

|

1898 Eddy Electric Mfg. Co., Electric Carriage Motor

1898 Eddy Electric Mfg. Co., Electric Carriage Motor

1898 Eddy Electric Mfg. Co., Electric Carriage Motor Chart

1898 Eddy Electric Mfg. Co., Electric Carriage Motor Chart

|

|