Image

|

Title: |

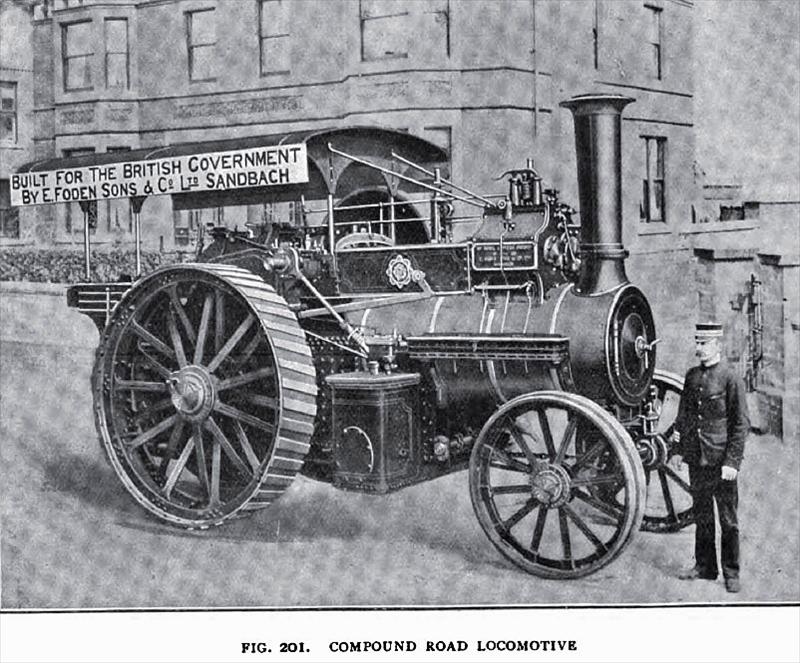

1904 Article-E. Foden, Sons & Co., Ltd., Compound Steam Road Locomotive |

|

Source: |

English and American Steam Carriages and Traction Engines 1904 pg 321 |

|

Insert Date: |

8/17/2011 7:48:03 AM |

|

MESSRS. E. FODEN, SONS, AND CO., SANDBACH —The illustration, Fig. 201, shows a compound road locomotive, built for the British Government by Messrs. Foden. The advantages of the compound road locomotive are as follows. The strain on the gearing is reduced to a minimum, or less than half required to move the same load with a single engine. They can be moved at a slow rate—an important advantage in hooking on; they are able to start a heavy load gradually, whereas with a single engine the load is started with a jerk. The strain on the gearing, and therefore on the travelling wheels, being uniform throughout the stroke of the engine, enables it to carry better over soft, greasy roads. Priming is practically done away with in the compound The boiler is made throughout of Siemens' mild steel; the barrel is 7/16 in. thick, the fire-box 3/8 in. thick, the tube and horn-plates are 1/2 in. thick. A 6-horse compound road locomotive contains fifty-six 1¾ in. tubes; the working pressure is 160 Ibs. per square inch. The cylinders are steam-jacketed; the steam chests are placed outside each cylinder, thus rendering the valves easy of access for refacing or adjustment. A double high-pressure arrangement is fitted to the compound cylinders, by means of which high-pressure steam can be admitted into both cylinders directly from the boiler, and each exhausts independently in the chimney. For starting heavy loads, getting out of soft places, or for ascending steep inclines, this auxiliary gear is of great advantage. Ramsbottom piston-rings are used, forming a steam-tight joint with the cylinder. The large end bearing of the connecting-rod is of phosphor-bronze; the end of the rod is forged solid, and afterwards the space for the bearing is cut away, forming a fork-end; the bearing is secured by dovetailed steel block and bolt, cottar, and pins. Balance weights are strapped to the crank sweeps. The compensating-gear centre is riveted to the main spur-ring by plug-fit rivets, supporting in position two strong steel pinions secured by large turned pins; one of the bevel-wheels is keyed to the axle, and the other riveted to the travelling - wheel. Some of Messrs. Foden's driving-wheels are fitted with tough cast-iron rims, but in the engine illustrated steel tee-rings are used of large diameter, with the usual cross strips; the riveted holes are drilled in position, and the riveting done by pneumatic machinery; the two webs of the tee-rings are held together sideways by means of large bolts, as shown. The fore wheels are made with cast-iron rims, hooped with mild - steel bands; the bosses are fitted with phosphor-bronze bushes. Strong laminated springs carry the hind part of the engine. Two or three travelling speeds are fitted to suit the requirements of customers. A fore tank is provided under the boiler barrel, connected to the hind tank in the usual manner; the pump draws its supply from the front tank as shown; the pump-plunger is cased with brass. Side plates are fitted for screening the working parts from view; a disc flywheel is also used for a similar purpose. An awning and a wood rack are included in the outfit. The high-speed governor acts on an equilibrium throttle-valve. A Ramsbottom safety-valve is mounted on the top of the cylinder. A winding-drum is keyed to the main axle. An efficient brake acts on the steel angles bolted to the rims of the driving-wheel. The main axle runs in phosphor-bronze bearings, and the gearing is all of crucible cast-steel from machine-cut patterns. Messrs. Foden's new spring arrangement has been dealt with in a previous chapter. |

|

1904 E. Foden, Sons & Co., Ltd., Compound Steam Road Locomotive

1904 E. Foden, Sons & Co., Ltd., Compound Steam Road Locomotive

|

|

|

|