|

Title: |

1895 Article-Egan Co., Hub Mortiser & Borer |

|

Source: |

Modern Mechanism 1895 pg 534 |

|

Insert Date: |

7/17/2011 8:06:16 PM |

|

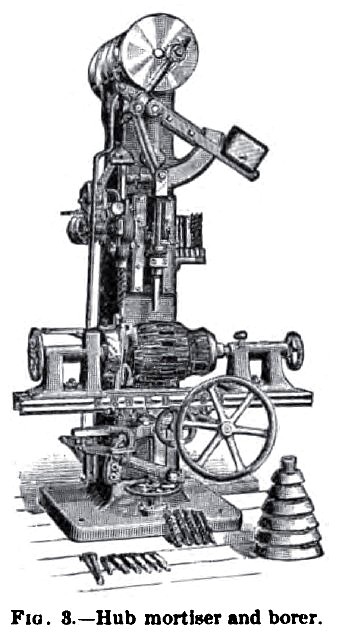

The Egan Hub Mortiser and Borer, shown in Fig. 3, has a single chisel bar with vertical stroke, the amount of which may be varied by altering the angle at. which the short connecting rod from the crank disk meets that from the upper end of the boring bar. The change in the stroke is accomplished by a treadle, and it is claimed for it that it prevents the slightest jar upon the foot even when mortising without first boring the hole to admit the chisel. The mortising chisel is reversible on the Jack-in-the-box plan, so as to cut either end of the mortise square. The boring mandrel has vertical traverse and is counterweighted; it is driven by beveled gearing from a horizontal axis belted at the back. The reverse may be controlled by the operator at will, or it will work automatically if set to do so. The boring bit is in line with the chisel, and there is a stop for gauging the depth of boring. The chuck for holding the hub is spaced to mortise for 10, 12, 14, 16, or 18 spokes, whether in line or staggering. One end of the hub is held by two jaws, parted by a right and left-hand screw. The other end of the hub rests in a cup of suitable size. The table has a lateral movement across the machine, parallel with the hub axis, the cross feed being given by a and wheel. An automatic double-chisel hub-mortising machine, constructed for mortising or re-mortising hubs from 6 to 16½ in. in diameter, and cutting mortises in hard wood up to 2½ in. wide and 5½ in. long, either straight or staggered. In operation, the table carrying the hub is lifted to the chisels until the full depth of cut is reached, and remains stationary until the mortise is complete, when it descends, the hub turning one notch of an index plate, ready for the next mortise. The gigging, spacing, feeding, etc., are automatic. The capacity is 75 to 80 hubs per hour. The operator starts either the boring or the mortising bar, as desired, by a friction gear and treadle. In relieving the friction an automatic brake is applied, stopping the machine at once. |

|

1895 Egan Co., Hub Mortiser & Borer

1895 Egan Co., Hub Mortiser & Borer

|

|