|

Title: |

1908 Article-H. B. Underwood & Co., Crankpin Turner & Reborer |

|

Source: |

Railway Age Gazette 20 Jun 1908 pg 269 |

|

Insert Date: |

3/27/2015 9:04:14 AM |

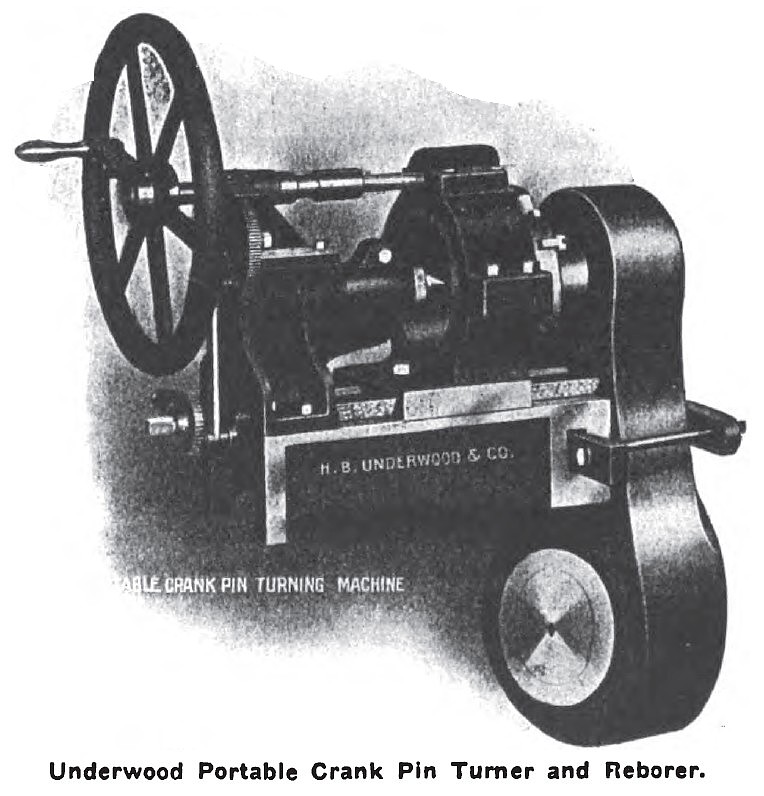

UNDERWOOD PORTABLE CRANK PIN TURNER AND REBORER—To meet increased demands for efficiency and speed, H. B. Underwood & Co., of Philadelphia, have put out a new crank pin turner and reborer designed for general work on locomotives and engines having dish and plain cranks. The machine is quickly adjusted, firmly held in place and, when necessary, will rebore the hole and at the same setting finish a rough turned pin after it is forced in and riveted.

The machine has a bed, with a suitable angle plate on the end, with a large slot running through it, made for a strong clamp of heavy dimensions for clamping to the crank. Should the crank not be machined true, an auxiliary plate is clamped to the crank in a secure and true manner, and the machine is then fastened to this plate. The machine also has a large adjustable center, which is arranged to go into the original center of the crank pin, thereby giving it the original alignment. This assists in testing the pin, by allowing the revolving cutter to turn oft the eccentric part, which is usually left by wear. Heavy cuts can be taken without chattering and an oil or water finish made so accurately that variation cannot be found with a micrometer. The machine can be taken off the bed in five or ten minutes, and replaced exactly central and true. It is a great convenience in handling the larger sizes (15 to 20 inches), to place the bed and attach it near its true position, then place the cutterhead, and lastly the driving and feed mechanism. This latter feeds either way, and can be adjusted from one notch to several, giving a variety of feeds to suit the material and operator.

The driving shaft is telescoped so that it drives the cutting tool forcefully all along the travel. A cut can be started In the center of the pin and run up to a shoulder or collar without changing the tool which is a straight flat piece of good tool steel, securely held and adjustable.

The machine will carry a boring bar, which is placed in the center and through a disc, fitting in the circular cutterhead, for reboring a hole. The same feed operates internally as accurately as externally, when turning off the pin.

The dismantling feature of the machine is absolutely necessary when the crank pin hole is to be bored and a new pin put in. The bed Is left attached to the crank, with the feed and turning mechanism removed, then the pin can be forced in, secured, and absolutely returned to size, perfectly true, as to hole and bearing surface.

The machine is built in the following sizes:—No. 1 taking from 7 Inches diameter and down, No. 2 taking from 12 inches diameter down to 6 Inches, No. 3 taking from 15 inches diameter down to 10 inches and No. 4 taking from 20 inches diameter down to 15 inches.

The designing of this tool resulted from the demand to re-turn pins of large diameter, and also to renew worn and loose pins when the hole is bad from looseness of the pin. |

|

1980 H. B. Underwood & Co., Crankpin Turner & Reborer

1980 H. B. Underwood & Co., Crankpin Turner & Reborer

|

|