|

Title: |

1904 Article-Iroquois Iron Works, Steam Macadam Road Roller |

|

Source: |

Good Roads Magazine Sep 1904 pg 245 & Oct 1904 pg 502 |

|

Insert Date: |

6/30/2011 5:28:54 PM |

|

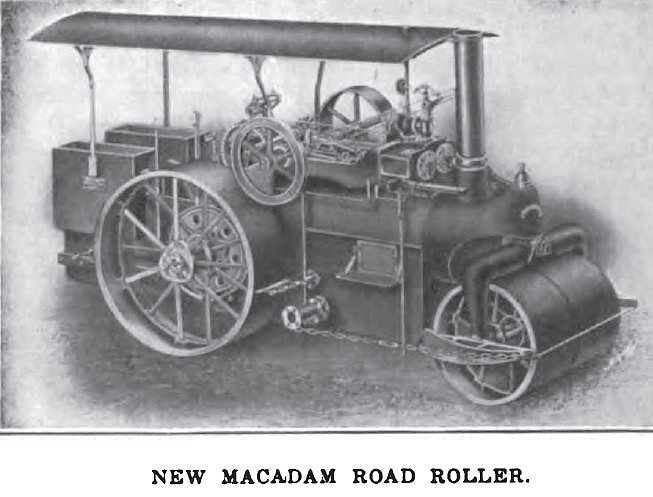

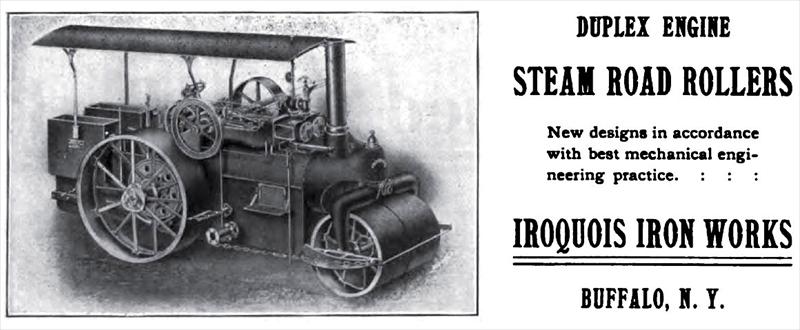

New Steam Road Roller-A new macadam road roller is now being placed on the market by the Iroquois Iron Works, Buffalo, N. Y. In design, as shown in the accompanying illustration, the roller follows that of the English locomotive type boiler, surmounted by a horizontal engine. In the matter of detail, however, the manufacturers have brought out new designs, which, it is claimed, effect not only a better mechanical appearance, but an increased durability and facilitate the care and operation of the machine. The rolls are cast of charcoal iron in a chill, giving a mixture with a surface similar to a car wheel. The face of the driving roll is beveled, preserving the contour of the road and insuring a smooth finish. For tearing up old roads, hardened spikes are inserted. Either one or both rolls are made fast to the driving axle by locking pins. The steering rolls are bronze bushed, operated by worm and gear in dust proof case, tread overlapping that of the driving rolls. The steel king post passes through the neck casting or saddle, and hinges on the yoke, which is of cast steel. The weight transmitted through the saddle is taken on a ball bearing, this being calculated to facilitate the hand operation of the steering roll. The boiler is constructed of flange, and fire box open hearth steel, sections being proportioned for 150-lb. working pressure, allowing a safety factor of 5. The top of the barrel, beneath the dome, is perforated, thus forming a baffle plate for wet steam. The toiler is provided with numerous hand holes for cleaning, two injectors and muffled safety valve. There are two water tanks of large capacity, one being located under the boiler barrel, and the other beneath the platform. The coal boxes are set at the sides of the platform with a passageway between, which constitutes a valuable improvement as the operator is allowed more room in which to handle his fire tools. The engine is duplex. For the purpose of operating a machine, which is constantly stopped and reversed, the double engine makes possible advantages that one engine cannot give. The steam dome, chest, cylinders and engine frame are in one casting. The dome is high, and sets over the dry plate formed by the shell. The engine frame, or bed, is completely enclosed at sides or bottom, the crank end resting on the gear boxing casting and in a sliding joint. The box holding the gear train is bolted to the horn plate on the sides of the furnace. In the matter of gearing, the two-speed gear has been discarded. The same speed and power results, however, it is claimed, are obtained by adopting an intermediate velocity ratio, by slightly increasing the cylinder bores and by constructing the boiler for higher steam pressures, thus by steam pressure and throttle control the engine can deliver through this gearing the speed and power changes desired, which as a fact are very slight. The details of the engine are in accord with up to date shop methods, journals being fitted with renewable white metal bushings, the bronze cross-head slippers being renewable without having to remove the cross-heads. All parts are made interchangeable. |

|

1904 Iroquois Iron Works, Steam Macadam Road Roller

1904 Iroquois Iron Works, Steam Macadam Road Roller

1904 Iroquois Iron Works, Steam Macadam Road Roller

1904 Iroquois Iron Works, Steam Macadam Road Roller

|

|