|

Title: |

1895 Article-States Machine Co., Boring & Milling Machine |

|

Source: |

Modern Mechanism 1895 pg 508-509 |

|

Insert Date: |

6/21/2011 8:38:30 PM |

|

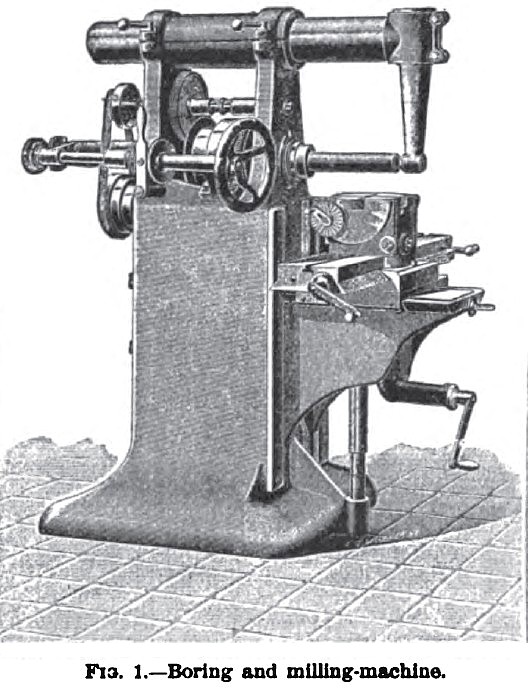

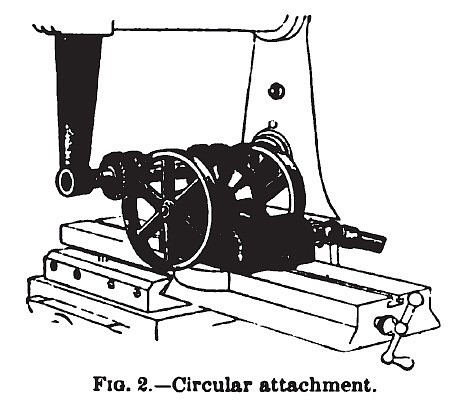

Universal Milling and Boring Machine—Fig. 1 shows a combined boring and milling machine made by the States Machine Co., of Newark, N. J. The inner or boring spindle, reamed for a Morse socket, has a power-feed 13 in. in both directions, and its thrust, directly from the back, is operated by a screw attached to it by an interlocking device. Feed is taken from a worm on the main spindle and is geared to a feed-shaft for hand or power feed. This feed-shaft, on its front end, has a hand-wheel, giving a quick return. From there it extends to the end of the main spindles, where it is geared to the feed-screw by a sensitive friction-gear, so that the power-feed can be set, in case a drill be dull or feed too fast, to regulate the thrust automatically, as a workman would by hand. The overhead arm supports a detachable drill-jig pendant. The platen has an adjustment graduated to .001 in., and has deep-grooved T-slots open at either end, with a circular T-slot and attachment-seat in the center. The platen can be turned at any angle or all the way around, and fastened where desired. The knee has an adjustment up and down, graduated to .001 in., and the saddle upon the knee has an adjustment to and from the column graduated to .001 in. When used as a milling-machine the main spindle, 3 in. in diameter does all the milling independent of the telescoping spindle, which does all the boring and drilling. Milling arbors and chucks screw on to the main spindle as face-plates do on lathes. The milling-feed is driven from the overhead gears, which are mounted on the milling-feed shaft, and slide into position endwise upon feathered keys; therefore either of them may be engaged with the spindle-gears. The feed-shaft pulley is belted to feed-cones, and these are connected to the platen by a pair of universal joints. There are 16 changes of milling-feed. The platen is fed by power 24 in., and operates at angle adjustments as well as the usual cross-position. The elevating, cross, and traverse adjustments are respectively 18 in., 24 in., and 12 in. A circular milling attachment for this machine, shown in Fig. 2, is used in machining gear-blanks, balance-wheels (which are milled between the spokes as well as the periphery), pistons, and such other circular pieces as need the whole or part of their surfaces concentric to a given point. It is especially useful in duplicate work, when many parts of the same character are required. |

|

1895 States Machine Co., Boring & Milling Machine

1895 States Machine Co., Boring & Milling Machine

1895 States Machine Co., Circular Milling Attachment

1895 States Machine Co., Circular Milling Attachment

|

|