Image

Manufactured By:

J. A. Fay & Co.

Keene, NH; South Keene, NH; Worcester, MA; Norwich, CT; Cincinnati, OH

|

|

|

Title: |

1895 Article-J. A. Fay & Co., Gauge Wood-Turning Lathe |

|

Source: |

Modern Mechanism 1895 pgs 468-469 |

|

Insert Date: |

6/21/2011 12:53:35 PM |

|

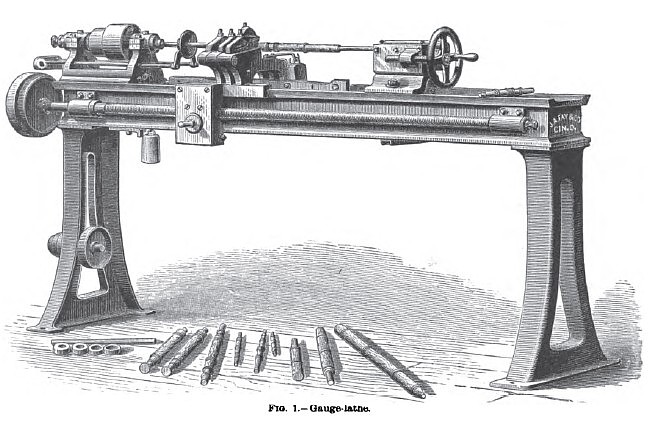

Gauge-Lathes—In some gauge-lathes employing a pattern of the same general outline as the finished product is to be, the " former" is placed upon the frame which carries the stock, but at a greater distance from the center, necessitating its being of a greater diameter and all its dimensions exaggerated. In others it is placed in actual line with the stock: and in such case it may or may not be of the same diameter; but, whether it is or not, its outlines should be parallel to those which it is intended to produce in the finished piece. With such an arrangement as this the same form may be made to produce several diameters of finished pieces, by adjusting its height; all the finished pieces coming of the same outline. In one type of gauge-lathes, made by the Trevor Manufacturing Co., the form is a sheet metal pattern, placed edgewise along the machine, and its curved upper outlines cause a rocking back and forth of the cutting-knives, which are given traverse along the stock, as the latter is rotated between the live and the dead center by a weight and cord feed. A simple gauge-lathe (represented in Fig. 1), for turning all sorts of irregular forms, consists of an iron frame with planed ways, upon which are head and tool stocks, a tool-rest, and an apron traversing back and forth by a screw. The head-stock carries a spindle, a cone-driving pulley, and a small feed-pulley. There is a self-centering attachment, which receives and centers the material without stopping the lathe. The tool-stock center rotates with the turning-stock, making both centers live. The tool-rest, which is gibbed to the planed ways of the frame, carries three cutters and a supporting ring, and may be moved either by hand or automatically fed by a heavy screw speeded from the head-spindle. The patterns are cut from sheet-iron of the exact profile of the finished article. As the work turns, the rest bearing the tools has lengthwise traverse, and is made to advance or recede from the center by the sheet-iron form, thus producing articles of any desired contour, having all their sections circular. |

|

1895 J. A. Fay & Co., Gauge Wood-Turning Lathe

1895 J. A. Fay & Co., Gauge Wood-Turning Lathe

|

|

|

|