|

Title: |

1893 Article-Wells Engine Co., Balanced Compound Steam Engine |

|

Source: |

Engineering mechanics V 14 Jun 1893 Pgs 168-169 |

|

Insert Date: |

11/23/2023 12:20:05 PM |

THE WELLS PATENT BALANCED COMPOUND AND QUADRUPLE EXPANSION ENGINE.

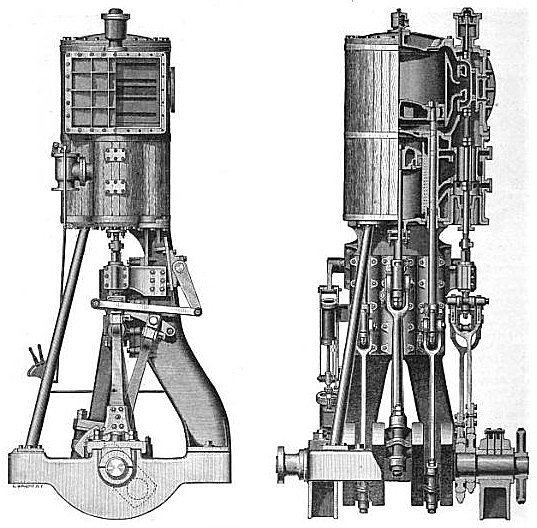

The accompanying cuts represent one of the larger powers of the Wells Compound Engine, made by the Wells Engine Company, 91 Liberty St., New York.

The economy of the compound system in marine and stationary work is well-known, but years of experimenting in Europe, and recently copied in America, has failed to produce even a fair "running" compound locomotive engine, or one that compares at all favorably with the unbalanced single cylinder engine in general use. This is owing to peculiar conditions and the limited space the engines must occupy, and also to greatly increased disturbing forces, caused by the additional weight of the moving parts of the engine, that it is impossible to balance even in a " simple." engine. For the above reasons it has been found impossible to improve upon the method adopted by Stephenson in the year 1812.

The so-called "non-condensing" cross-compound type were built and recommended (by their designers) as economizers.

The advantages claimed by this system are, that the steam exhausted from the small cylinder has " only" a distance of 6 or 8 feet to travel before it reaches the low pressure piston, and

that its pressure being gradually reduced by a receiver while in transit, enables the "pet" intercepting valve to handle what steam is left with great difficulty.

It is also claimed by reason of its " always unequal " forces applied to opposite sides of the locomotive, and the difference in weight of the two engines, that a much more perfect " curve" motion can be obtained, which is no doubt correct.

The four cylinder compound design has little respect for a "natural" balance of forces, although he, above all others would receive the greatest benefit, as he is from necessity obliged to add to the weight of the reciprocating parts, which increases the disturbing forces, and is also obliged to transmit the steam forces out of line, which not only consumes their power but " effectually " prohibits high speed of locomotives.

The unique system of the Wells Balanced Compound Engine yields a perfect motion, that heretofore has never been attained. With this attachment, the locomotive is relieved of all disturbing forces and becomes a balanced mass moving in a straight line. The steam pressures being balanced within the cylinders, no strains can escape into the frame.

The weight of the high the and low pressure pistons, and their connections being equal, and attached to opposite sides of the axle, with equal steam pressures applied, moving in opposite directions in the same plane, gives an equilibrium in all forces acting around the axles, at all angles of the cranks and at all speeds, obviating the use of counter-weights in the driving wheels, and preventing oscillating and jerking motions and also removing all lateral strains. In forward motion the position of the axle will be constant upon the forward side of the pedestal boxes—preventing back and forward motion, and causing the whole train to move as if pulled with a steady force in one direction. All forces acting in the Wells Engine are controlled by the cylinders and cranks. The cylinder heads acting as the fulcrum for the steam pressures, the double acting "couple" cranks become the sole "controllers" and transmitters of all forces acting outside of the cylinders. The cranks are constructed from a slab of hammered steel, and are so proportioned that either crank has ample strength to transmit its force independently. The inside crank pin having a diameter of 7 inches or an area of 44 inches to resist "one-half" of the torsion from the force exerted by the small piston, and it would require a force of more than a 1,000 tons to twist it off, while the drivers will slip under less than 20 tons. Their weight being balanced around the axles, it would be equivalent to adding a 1,000 lbs. to the weight of perfectly balanced driving wheels.

Durability.

It is hardly to be supposed that the weight of the heaviest locomotive would injure the rail or road-bed at a state of rest, (a condition that applies to the Wells system "in motion ") therefore, the inequalities and escape of forces produced by motion, must account for all wear and tear, outside of a rolling friction. These forces have never been controlled, but are resisted by the engine frame and pedestal bearings, and finally by the rails and road-bed. It is a " thrasher" and all the word implies, and is only kept upon the rails by the weight of the whole mass and by the flanges of the driving wheels. By the Wells System the engine frames and pedestal bearings are relieved from all strains and pressures due to the steam and also from the thrust of the rods. All of its moving parts having a "natural" balance, no counter-weights in the driving wheels are required. Hence, the momentum of all moving parts, "the only" elements that tend to destroy the locomotive rails and road-bed are by this method eliminated, and, at high speed, only the inequalities of rail and road-bed would increase the wear and tear as they are only subject to a crushing force from the weight of the locomotive. A balanced mass propelled by a perfect motion will relieve the bridges of all injurious strains excepting those caused by its weight and will maintain the most perfect condition of rail and road-bed. As an engine for elevated railway service, it will not only save the structure, but will permit the use of much heavier locomotives.

High Speed With Increased Safety.

The additional safety afforded by this principle will be apparent, when it is understood that all forces are exerted in keeping the locomotive in a “straight" line, and there being no disturbing forces, its whole weight is constantly on the rails. Therefore, with a straight "true" track it will have no more tendency to leave it at high, than it would at slow speed.

There is no engine that approaches it in rapidity of motion and none so easily controlled. When making 800 revolutions per minute (placed loosely upon a common floor, with no fastening whatever), by closing the ports it stops instantaneously and without jar; neither will reversing it, under full steam and speed injure it, as it is balanced. It is so simple that it can be attached to the standard locomotive in good mechanical form and requires no additional valve gear.

Economy In Fuel.

Compared to the best type of "compound" marine engine, the Balance principle shows a reduced fuel consumption of

about one-third, and no doubt will show a still further marked reduction when applied to the locomotive, owing to extreme steam pressures that are required to do the work, 80 lbs. following one-fourth stroke in a single cylinder being the economical limit of pressure, where 150 to 180 lbs. are used to do the work. The cylinders are in this case arranged in the most compact form, which gives the least distance for the steam to travel, and the cranks being set 180 degrees, the low pressure piston is "always" in position to receive the exhaust steam from the high pressure cylinder, giving a "continuous" force from high to low pressure piston; this will reduce the losses from condensation and undue expansion. The steam pressures and also the momentum forces being balanced " greatly" reduces compression and friction, as in this case, the pedestal bearings are only required to carry the weight of the locomotive, and the pressure that is required to haul the train. (The gain can easily be determined by multiplying the area of piston, by the steam pressures and the weight of the pistons and rods by their velocity. The uniformity of forces applied to the driving wheels and the absence of counter-weights, will prevent slippage and increase its traction force. The locomotive moving in a straight line reduces the friction upon the flanges. This principle embraces another peculiar and very valuable feature, directly the reverse of the general practice, i.e., Its perfect control of the momentum forces for useful effect. In this they are united with the steam forces in turning the driving wheels, while in all other engines they retard their motion, as a large percentage of the power is thrown off through the frame pedestal boxes and finally into the rails and road-bed.

US Patent: 278,841

https://datamp.org/patents/displayPatent.php?number=278841&typeCode=0 |

|

1893 Wells Engine Co., Balanced Compound Steam Engine

1893 Wells Engine Co., Balanced Compound Steam Engine

|

|