|

Title: |

1895 Article-Westinghouse Machine Co., Compound Steam Engine |

|

Source: |

Modern Mechanism 1895 pg 315-317 |

|

Insert Date: |

6/11/2011 5:56:46 PM |

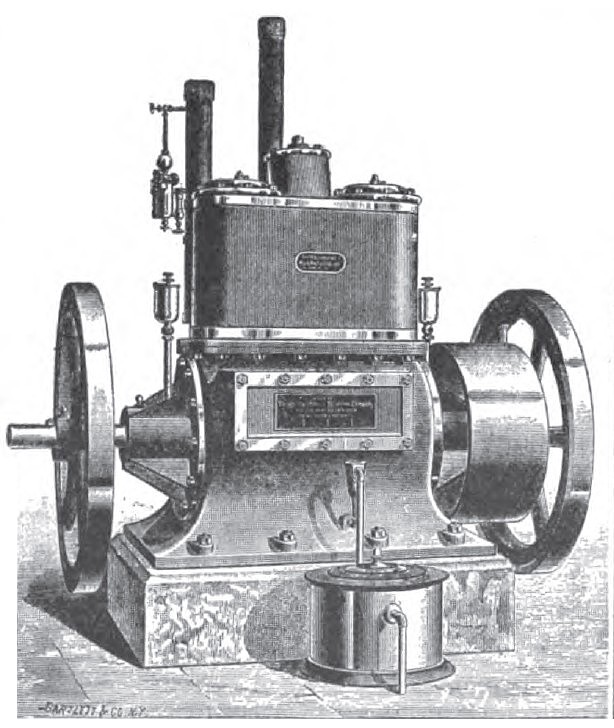

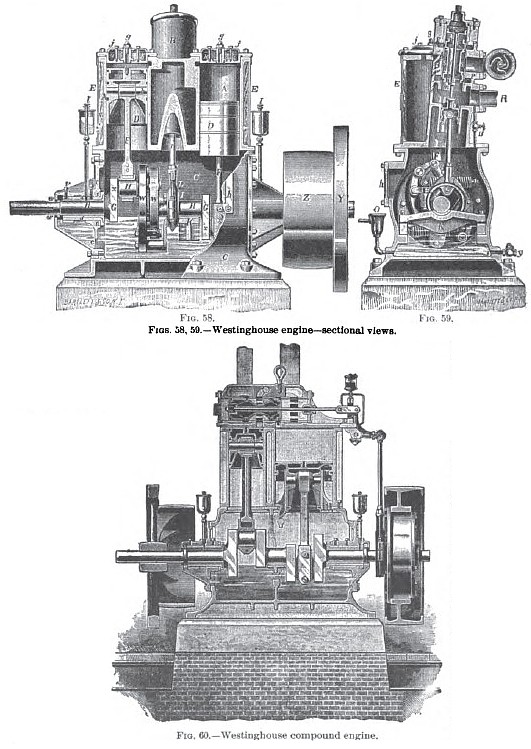

The Westinghouse Engine.—The Westinghouse engine is the leading engine of a new type which has recently come into extensive use, the principal characteristics of which are (1) two or more vertical single-acting cylinders, and (2) automatic lubrication by moans of a closed chamber surrounding the crank-shaft, containing oil or oil and water. This type of engines was originally built with two cylinders of the same size, with cranks at 180°. Large sizes are built as a compound engine, with one cylinder larger than the other. Engines on the same general principle, but with three cylinders and triple expansion, with three cranks at 120°, have been brought out by other makers. Among the advantages claimed for this type of engine are, that, on account of its being single-acting, the pressure of the piston and of the connecting-rods on the wrist and crank pins is al ways in one direction, viz., downward, and consequently, no matter how much the bearings are worn, there is no lost motion in them. On this account, the engine, if properly designed, may be run at a very high speed, and is therefore economical of room and weight, and saves the gearing for transmission of power to the line-shafting machine or dynamo, necessary with slow-speed engines. Fig. 57 shows a front view, and Figs. 58 and 59 sectional views, of the Westinghouse "standard" or non-compound engine as built in sizes from 15 to 250 horse-power. The following is a description of the details: The cylinders A A are cast in one piece with the valve-chamber B. and are bolted to the top of the bed or crank-case C. The cylinder-heads a a cover the upper ends of the cylinders only, the lower ends being uncovered and opening directly into the chamber of the crankcase. The pistons D D are of the "trunk" form, double-walled at the top to prevent condensation, open at the bottom, and carrying the hardened steel wrist-pins b b. They are each packed with three rings. The connecting-rods FF are made of forged steel. The cranks G O, the crank-pins, and crank-shaft H H are all of steel, and may be removed by taking off the crank-case head e. The crank-shaft bearings are in the form of removable shells d d, lined with Babbitt-metal. From 60 horse-power up these bearings are split for the sake of i venient removal without taking out the shaft. They are slipped into the crank-case I from the inside, and adjusted by a distance-ring /. which is of an arbitrary thickness dependent on the shrinkage of the casting of the crank-case. A chamber is formed in the outer end of the crank-case head, in which, and revolving with the shaft, is the ring-wiper u; which takes up the oil as it works past the bearings, and returns it through the hollow rib e into the crank-case C. Oil is fed to the engine from the sight-feed cups / / on the main bearings; this renders all other lubrication unnecessary, and keeps the engine clean. A siphon overflow, with a funnel head 0, prevents any accumulation of water from rising above the level of the bottom of the shaft, and thus prevents the escape of oil. This overflow may be piped off at the hole in the funnel-head to an oil-separator, shown in Fig. 59, from which it can be skimmed and restored to the crank-case. An adjustable center-bearing A' bridges the crank-case, and receives the thrust of the pistons. The bonnet A is removed, to give access to the cranks. The valve V is a piston-valve, packed with two rings in each head. The valve-seat is a removable bushing, in which the ports are cut to an exact register, and which is then forced into its shoulders. Each valve is provided with a Fig. 60.—Westinghouse compound engine. back - pressure piston, which prevents the balance of the governor from being disturbed when the engine exhausts against back-pressure. The valve-guide J serves also in lieu of a stuffing-box against the exhaust steam contained in the passage above it. The valve-guide as well as the valve and both pistons are packed with simple sprung rings of cast iron. The valve-stem m is keyed fast to the guide, and grips the valve without binding between the nut at the upper end and the collar at the lower end, as shown. The band-wheel is a combination-pulley Z and fly-wheel Y, cast together, so that the pulley overhangs the main bearing, throwing the line of belt-strain well toward the center of the bearing, and taking the spring off from the shaft. The automatic governor is located on the shaft, between the cranks, and actuates the valve direct without rock-shafts or other mechanism.

The Westinghouse Compound Engine is similar in general characteristics to the non-compound engine above described. It is shown in section in Pig. 60. One cylinder is enlarged to practically three times the area of the other. The valve-chest is across the top of the cylinders, and is in one piece, the various steam-passages being chambered in it. The valve-seat is in the form of a bush, in which the ports are cut to an exact register. This bushing is reamed out and forced steam-tight into its bored seat.

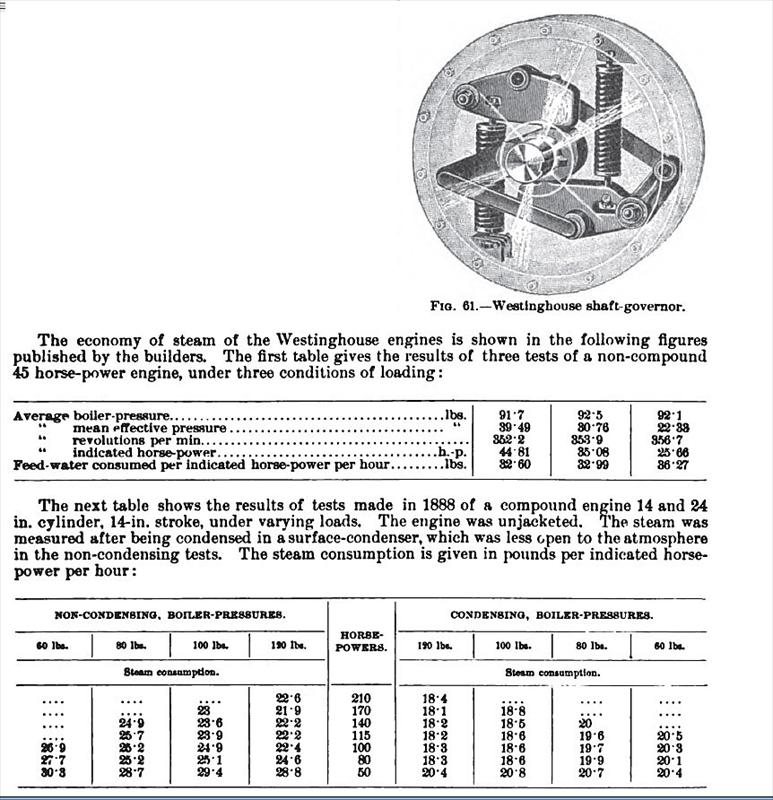

The valve-chest also contains a small by-pass valve controlling a cored passage, by which live steam can be admitted to the low-pressure cylinder, to turn the engine over its center when starting. The steam and exhaust connections, are on the side of the valve-chest toward the back of the engine. The valve is actuated by a single eccentric controlled by a shaft-governor, shown in Fig. 61. It is enclosed in a case which is filled with oil when the engine is first set up. and requires no further attention for an indefinite period. The eccentric alone is out-side of the governor-case, being carried on a shaft running through a sleeve, and bearing against stops when at full throw. |

|

1895 Westinghouse Machine Co., Compound Steam Engine

1895 Westinghouse Machine Co., Compound Steam Engine

1895 Westinghouse Machine Co., Compound Steam Engine Sectional Views

1895 Westinghouse Machine Co., Compound Steam Engine Sectional Views

1895 Westinghouse Machine Co., Compound Steam Engine Governor

1895 Westinghouse Machine Co., Compound Steam Engine Governor

|

|