|

Title: |

1895 Article-McIntosh, Seymour & Co., Steam Engine |

|

Source: |

Modern Mechanism 1895 pgs 307-308 |

|

Insert Date: |

6/9/2011 8:40:00 PM |

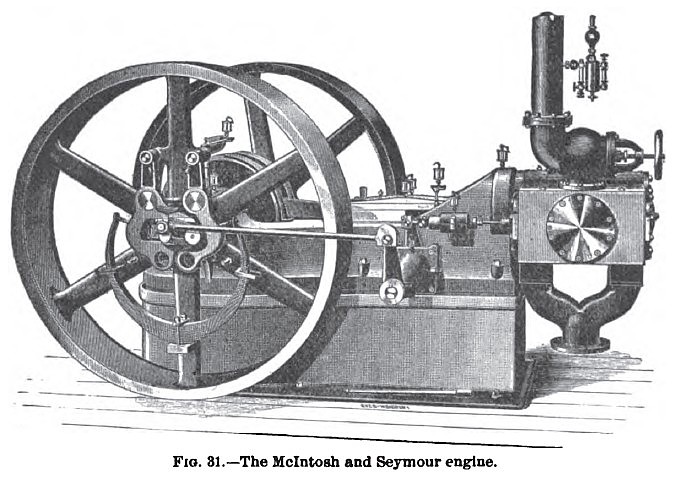

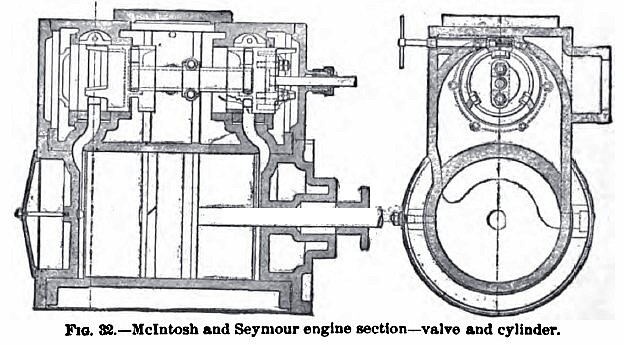

The McIntosh & Seymour Engine is shown in Fig. 31. Fig. 32 shows a sectional view of the valve and cylinder.

The general design of the engine presents no radically novel features except in two vital points, the valve and governor. The frame is made very massive and rigid by heavy internal ribbing. The lower guides are separate pieces, though supported throughout their entire length by the frame. The main bearings have cheek-pieces for taking up horizontal wear. Each one of these is backed up solidly for its entire length by a taper-wedge, and can be adjusted by elevating the wedge with screws provided for that purpose. The main caps can be removed entirely without disturbing the cheek-pieces or wedges, and the latter can then be removed without disturbing the shaft, exposing over one half of the circumference of the journal. The cross-head is of the locomotive type and is made of one piece, including cross-head pin. The construction of the valve and valve-scat is shown in the sectional views through cylinder and steam-chest, in Fig. 32. The valve proper is an ordinary piston-valve. The valve-seat is so constructed that it can be taken up to compensate for its own wear and that of the valve. This seat consists of a ring, or rather two rings, made in one piece and connected by several bridges across the port-opening which the space between them forms. The seat is crescent-shaped, split and adjustable to fit the valve, by the stem which extends to the upper side of the steam-chest, where it can be turned by a box-wrench, as shown in the cut, after removing the cap which covers its end. By disconnecting the eccentric-rod from the valve-rod slide or rocker and moving the valve to and fro by hand while turning the stems, a very close adjustment of the seats to the valve can be made without any danger of making them too tight for the valve to work freely. Each adjustable seat is held steam-tight between two permanent seats, but is free to move in the plane of the port and may be said to ride on the valve. This arrangement makes the valve less liable to stick than with a rigid seat, if the engine is started without warming it up thoroughly. The steam does not enter the port-openings from the steam-chest over the inside edge of each valve-end, as is usually the case, but through port-shaped openings in the rim of the valve, leaving a detached portion on the inner edge of each valve-rim, which greatly increases the bearing-surface of the valve. This engine has proved exceedingly efficient as a" motor for dynamos. |

|

1895 McIntosh, Seymour & Co., Steam Engine

1895 McIntosh, Seymour & Co., Steam Engine

1895 McIntosh, Seymour & Co., Steam Engine Section

1895 McIntosh, Seymour & Co., Steam Engine Section

|

|