|

Title: |

1895 Article-Stearns Manufacturing Co., Woodbury Steam Engine |

|

Source: |

Modern Mechanism 1895 pg 301-302 |

|

Insert Date: |

6/8/2011 9:48:44 PM |

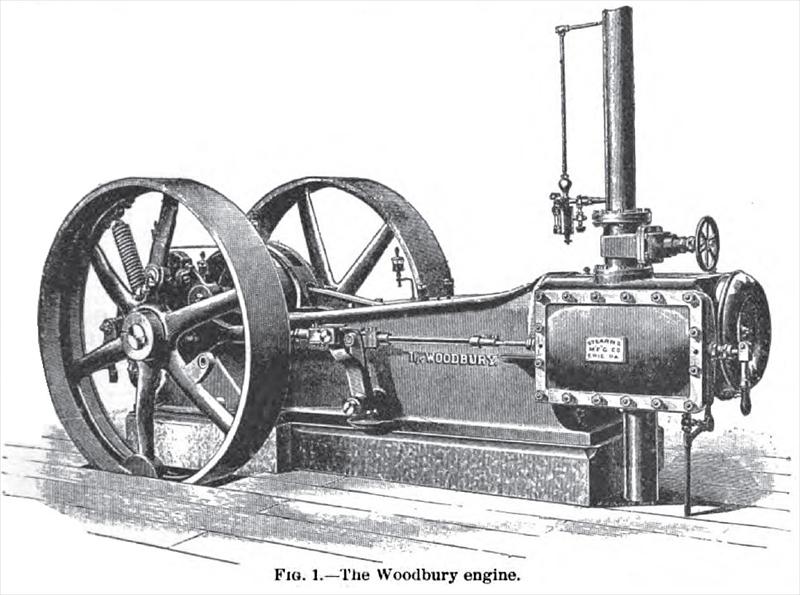

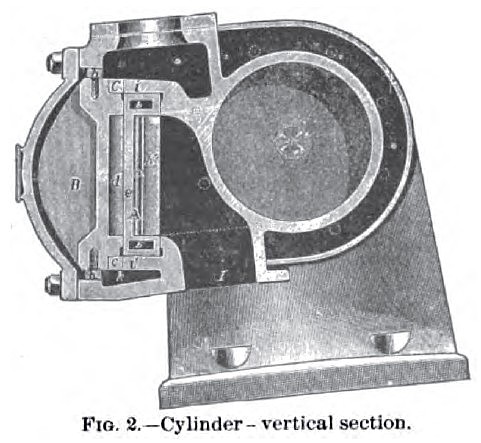

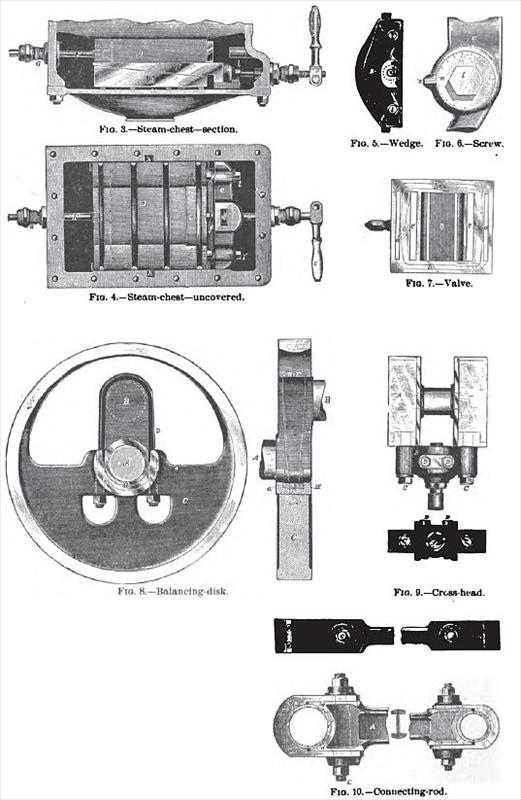

The Woodbury Engine is shown in perspective in Fig. 1. Fig. 2 is a vertical section through the cylinder and valve. Fig. 3 is a horizontal section through the steam-chest above the top of the valve. Fig. 4 shows the steam-chest with cover removed, exhibiting the back of the relief-plate and wedge. Fig. 5 is an end view of the relief-plate and wedge. Fig. (1 is an enlarged view of the upper adjusting screw; and Fig. 7 is a back view of the valve.

Referring to Fig. 2, steam-pressure is eliminated from the valve A by the relief-plate B on the back, which is supported against steam-pressure at top and bottom by a forked or double wedge 6* whose length is about equal to that of the relief-plate. It is obvious that a longitudinal movement of the wedges inward will force the relief-plate away from the valve, and the outward movement of the wedges will let it down toward the valve. The movement of the wedges, and consequent adjustment of relief-plate, is accomplished by the two adjusting screws 11' (Fig. 8), which fit loosely through the cross-piece of wedge and are tapped into the relief-plate. The collars m, which form part of adjusting screws, are notched on their peripheries, as shown in Fig. 6, and a notch n is made on the wedge opposite each screw. The collar has 100 notches, and therefore admits of a definite degree of adjustment. The adjusting screw has 10 threads per in., and the taper of wedges is 1 in. in 10. One notch on the collar, therefore, representing 1/100 of a turn, moves the wedge lengthwise 1/1,000 of an in., and the relief-plate toward or from the valve 1/10,000 of an in., corresponding to 1/20,000 of an in. on each face of the valve. The passage k at the bottom of the chest allows a circulation of steam under the ledge, insuring equal temperatures for ledges ii. The screw D, which is operated from the outside by the handle E, is also used as a means of moving the wedges inward and throwing off the relief plate; but the plate can not be let down farther than the adjustment allows, as the wedges can not be drawn back farther than the collars m of screws I V (Fig. 6). The amount of inward movement is regulated by the screw/ (Fig. 4) which forms the stop for the inward movement of the wedges. This screw taps into the relief plate, and against its head the cross-piece of the wedge strikes. When the handle E is turned to the left as far as it will go, the wedges are back against the collars and are in proper working position; when, on the contrary, the handle is moved to the right, the screw which works through the stuffing-box forces the wedges inward and throws off the relief-plate. About one half turn of the handle is all that is necessary. The purpose of this handle and screw is to afford a means of separating the valve-faces from seats in case they tend to adhere together lifter engine has been standing for some time. The valve A (Fig. 8) besides taking steam at the ends, has supplemental admission ports a a (Fig. 7) which are connected at top and bottom by passages b b'. The steam is entering cylinder-port directly past the end of the valve, and also through the cavity in the relief-plate into port a'. Steam is at the same time entering supplemental port a at opposite end at two points, and traveling through the horizontal passages into port a' and cylinder-port. The admission, therefore, takes place at four points at the same time, and, as the ports are very large, the nearest approach to boiler-pressure is reached, and the usual loss between boiler and cylinder reduced. A double exhaust is also used.

Fig. 8 shows the method of attaching the counter-weighted disks to the cranks for the purpose of balancing the reciprocating parts.

Fig. 9 shows the cross-head in top and end view, the piston-rod being in section.

The construction of the main connecting-rod is shown in Fig. 10. |

|

1895 Stearns Manufacturing Co., Woodbury Steam Engine

1895 Stearns Manufacturing Co., Woodbury Steam Engine

1895 Stearns Manufacturing Co., Woodbury Steam Engine Cylinder

1895 Stearns Manufacturing Co., Woodbury Steam Engine Cylinder

1895 Stearns Manufacturing Co., Woodbury Steam Engine Parts

1895 Stearns Manufacturing Co., Woodbury Steam Engine Parts

|

|