|

Title: |

1871 article on More's patent spiral cutter-head |

|

Source: |

Manufacturer & Builder, March 1871, p. 57 |

|

Insert Date: |

2/18/2017 8:40:34 PM |

More’s Spiral Cutter

This invention relates to all kinds of rotary cutters used in wood-working machines in which the straight knives work at right angles to movement and grain of the wood. In the ordinary planing machine, straight knives set at right angles to the wood, and revolving in the direction of its motion, cut the surface away. Each cutter, of course, takes out a shaving as wide as the wood, and, when a great thickness is to be taken off, this is a very severe blow upon the machinery.

Instead of making the knife straight, Mr. John More twists it around the cylindrical body and makes the edge of the spiral, usually having one-third of a revolution, but it can be made of any twist; the greater the twist, the less power required. Our smaller engraving shows the construction of the cutter. If we examine into the action of a knife of this kind, we shall find that only a small part is in the wood at a time, and that the edge has a drawing motion. On account of this, the work is very much smoother than anything that can be done with the ordinary cutter-head with its direct chopping. Finished work can be turned out, such as door-panels which are ready for sand-papering. Some of the gnarled, crooked walnut which we have seen worked by this machine was as smooth as the jointer of the carpenter would have left it. The shavings are all sent to one side, showing the work clean as it leaves the machine, which is an important point. It can be made right or left hand twist, so as to throw the shavings upon either side. The noise is very much less than that of the ordinary cutter. In fact, it cannot be heard above that of the machine unless it is in the wood. Having a shearing motion, the knives do not become dull nearly as fast as those of the ordinary straight pattern. Another point worth attention is the mode of sharpening. This is done without taking the cutter from the machine, by taking off the driving-belt- and substituting another running over the feed-pulley in its place. A file or emery-plate is then placed in a suitable block and passed along the bed under the knives. This brings them down “true." A hone then takes the place, of the file, and finishes the job.

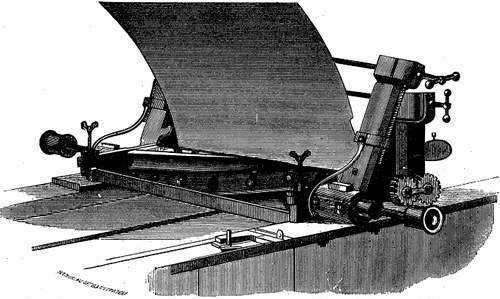

Our larger engraving shows the planing-machine with the spiral cutter in place. No alteration of the planer is necessary, as the spiral cutters fit into the same boxes and run with the same belts as the old. To test the efficiency of the machine, a series of trials were made, of which the following is a description:

In the experiments, one trial was made with an exchangeable head, the common head fitting exactly in the same place of the twisted or spiral head; it was the same head formerly used in that machine.

The spiral head was used without re-sharpening, and had evidently become partially dulled. The cutters in the old head were freshly ground and adjusted in the best condition. The spiral head beat the old head two to one; even with difference of condition against it.

Working in pine and gradually increasing the depth of the cut, the machine stopped with a shaving three eighths of an inch thick when the old cutter-head was used, but kept on to three quarters of an inch thick when the new spiral cutter-head was used.

Working in oak, it stopped at one quarter of an inch with the old, and at one half an inch with the new.

Working in walnut, it stopped at three sixteenths with the old, and one half an inch with the new, making a difference of more than one hundred per cent in the latter case. The pine lumber was sixteen and a quarter inches wide; the walnut seventeen and three quarters, and the oak eighteen inches; in every case the lumber compared was identical, and the belts and their tensions were the same.

In pine, the new cutter runs steadily and smoothly, taking off a shaving five eighths of an inch in thickness. We have seen it do the same thing in white wood.

The trials were fairly conducted, and showed a gain in the smoothness of the product, a. reduction in the noise, a reduction in the annoyance due to the shavings, and a very great increase in the capacity of the machine to plane bad stuff and to take a large shaving.

Mr. John More, of Messrs, Duke & More, No. 304 West Fifty-fourth street, New York, is the patentee; and the cutters are manufactured at the Huntington Machine-Works, Newark, N. J.

US Patent: 107,943

http://www.datamp.org/patents/displayPatent.php?number=107943&typeCode=0 |

|

More's Spiral Cutter

More's Spiral Cutter

The Cutter

The Cutter

|

|