|

Title: |

1911 Article-New Way Engine Co., Cylinder Grinding |

|

Source: |

Implement Age 26 Aug 1911 pg 30 |

|

Insert Date: |

4/26/2011 8:50:06 PM |

This is an age when every piece of mechanism is figured down to a nicety. The automobile has been the means of educating the professor, the doctor, the minister, the legislator, the farmer and the dealer into the differences between makes of engines, the reasons for these differences, and the advantages of certain ones over others.

The implement dealer of necessity is considerable of a mechanic; in fact he must be in order to do a successful business. Every progressive implement dealer handles one or more lines of gasoline engines; in fact a gasoline engine is now considered standard stock, the same as nails, binder twine, wagons, etc. The more the dealer knows about his gasoline engine line the better equipped he is to sell them. In order to sell his engines to advantage he should know the exclusive features of his line that distinguishes it from others and makes it worth while for him to handle them, as well as worth while for his customers to pay his price.

The day was when every little town had its own little gasoline engine plant, which turned out in its own crude way some farm engines as nearly like others in appearance and construction as the patent laws would permit. Accurate design and dimensions were not considered essential to success. As little machine work was done as possible, therefore these engines were sold at almost any price that the farmer would pay. These cheaper lines have furnished the advance educational campaign that has been going on with rapid strides all over our country ever since.

Some engine manufacturers soon learned that it paid them to be more particular in their rough castings, to be more accurate in their engine design, and to be more careful in their machine-shop work. At the same time dealers learned that it paid them to buy these carefully-built engines, to pay more for them, and to learn their better features so as to explain them to their trade. The dealers' customers also learned not to take for gospel truth every old thing told them, but to study the design and construction, the reasons for changes, and the way these changes will affect the operation of the engine. Right now the farmers of our country can discuss the different automobile engines and their supposed advantages more intelligently than the city people can who use these same automobiles every day.

Three Necessary Things

Three things are absolutely necessary to make any gasoline engine go; they are:

First: Good spark.

Second: Gasoline.

Third: Good compression.

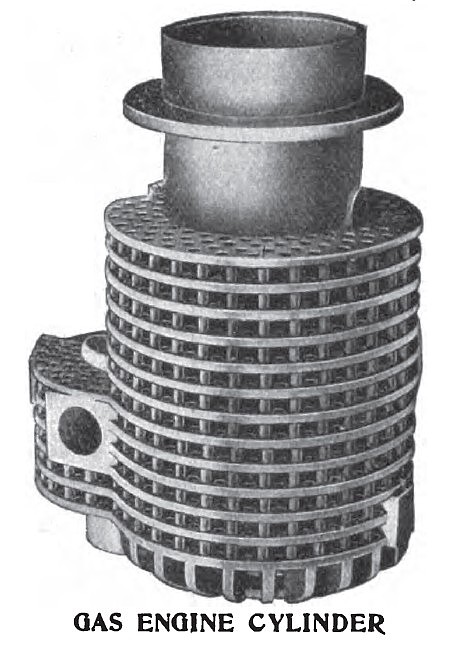

All three do their work in the cylinder of the engine. The electric spark and the gasoline have to be carried there so as to have the first ignite the second to produce the third. It will be easily seen that the cylinder is by far the most important part of the engine, and if the three points above mentioned are carefully looked after the balance of the engine may be rather crude, but still it will do some work.

The main difference, therefore, between gasoline engines is in their cylinder construction, because this affects almost every other part of the engine itself. The implement dealer should know how to detect these distinguishing marks and how to determine a high-grade engine from the cheaper class by its construction.

It Starts In the Foundry We have to go back to the beginning. The ordinary formula for cast iron will not give a

sufficiently hard casting to withstand the high temperature generated by a gasoline explosion. This means that great care must be taken to see that too much scrap iron is not thrown into the crucibles, as it will not mix thoroughly with the rest of the formula. Such castings leave soft spots that will blow out under pressure, and these spots often pass factory inspection, to be brought to light after the engine has been run some time. The fist distinguishing mark of a high-grade cylinder is made in the foundry itself.

Shape of Cylinder

A cylinder in two or more pieces means packed joints. This means trouble with packing, just as sure as the dealer lives. I costs no more and certainly saves everyone time and expense to have a cylinder made in one piece. This is another distinguishing mark of a high-grade cylinder.

Machining the Cylinder

No man would buy a good automobile that did not have its cylinders ground-finished. Very few automobiles, except for the very cheapest, are now built in any other way; the trade demands it in order to get the best compression without wasting gasoline. It is just as necessary to have the farm gasoline engine with a ground-finished cylinder as it is with an automobile. The majority of farm engines do not have ground cylinders simply because dealers and customers are not demanding their rights. Such cylinders are bored out with the ordinary machine tool and small ridges are necessarily left on the sides; the piston rings wear these ridges down, and in the process are worn down themselves. They never can be worn down true, so that in time the engine requires new rings and a new piston, or possibly a new cylinder, or it loses fully one-third of its power. This is why the ordinary gasoline engine, after a couple of years or more of service, is always spoken of as "losing its power."

What Grinding Does to the Cylinder

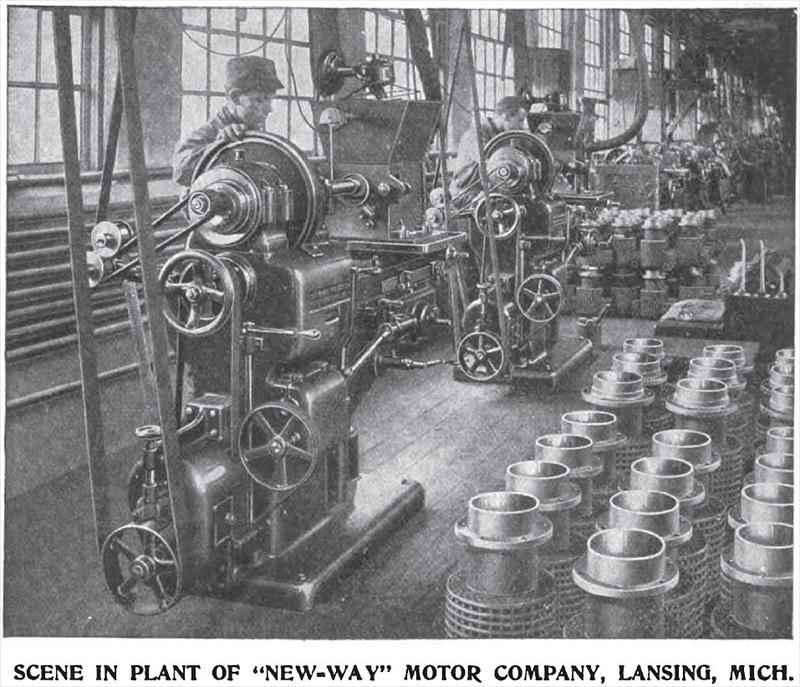

The cylinder is ground on special fine emery grinding machines, after it has been bored out just as true as machinery and tools will do the work; each cylinder is ground finished to an accuracy of less than one-thousandth of an inch; this is as fine as any tool can be made to do the work. The entire inner surface is as smooth as a highly-finished piece of glass. The piston is ground-finished in the same way. This means perfect compression; the same amount of gasoline will now last longer and actually produce more power. In other words, less gasoline is used and more power is developed, effecting a double saving.

Talk about conservation of our natural resources, why not consider a conservation of our pocketbooks? Less money spent on gasoline for the farm engine means more money to spend on gasoline for the farm automobile. Ground cylinders always mean many more years of service. The dealer should know that a ground-finished cylinder and piston, with ordinary care, will give just as good compression after years of service as on the day when sold. The dealer is past the age when the one-season automobile is sold; he is fast getting past the age when a one-year or two-year gasoline engine is sold; farmers now demand more for their money, and they have a perfect right to do so. The cut above shows a photo taken in the plant of “New Way” Motor Co., Lansing, Mich., and illustrates how all “new Way” engine cylinders are ground-finished. The machines that do this work are as delicately constructed as the machinery used to match the gears of a high-grade watch. In this run of two hundred "New-Way" engine cylinders by actual test and measurement there was a variation of less than one-fourth of one-thousandth of an inch. Such accuracy as this is not very common in engine factories, but it shows that farm engine cylinders can be given the same finishing treatment as high priced automobile engines, and that it pays to do it.

Poor compression means a waste of gasoline. Good compression means a saving of gasoline as well as increased power. The "New-Way" Motor Company advises that every "New Way" air-cooled engine has a ground-finished cylinder, piston and crank shaft. The first engines that this company put out are still giving efficient, service and not using any more gasoline per horsepower than was used the first day they were run. These engines can be taken apart and the pistons and cylinder will show perfectly smooth, clean, without even a scratch. They are good for practically a lifetime of service.

The engine dealer does not need to court trouble, he will be sure to have his share of it as long as he is in business, because some of his customers will fail to use good judgment at some time; but the dealer owes it to himself to see that he is not tied up to a trouble-making line. He should study the features of the engine he proposes to sell and select the one that includes the best and leaves off as many as possible of the ordinary trouble-makers. By looking closely to the cylinder construction of his engine line he will have solved in advance most of the things that will later be sure to come up to his less fortunate competitor, who has not been so careful in his selection. |

|

1911 New Way Engine Co., Gas Engine Cylinder

1911 New Way Engine Co., Gas Engine Cylinder

1911 New Way Engine Co., Gas Engine Cylinder Grinding Department

1911 New Way Engine Co., Gas Engine Cylinder Grinding Department

|

|