|

Title: |

1890 Article-Shipman Engine Mfg. Co., Shipman Steam Engine |

|

Source: |

The Steam User 1890 pg 111 |

|

Insert Date: |

4/20/2011 4:46:10 PM |

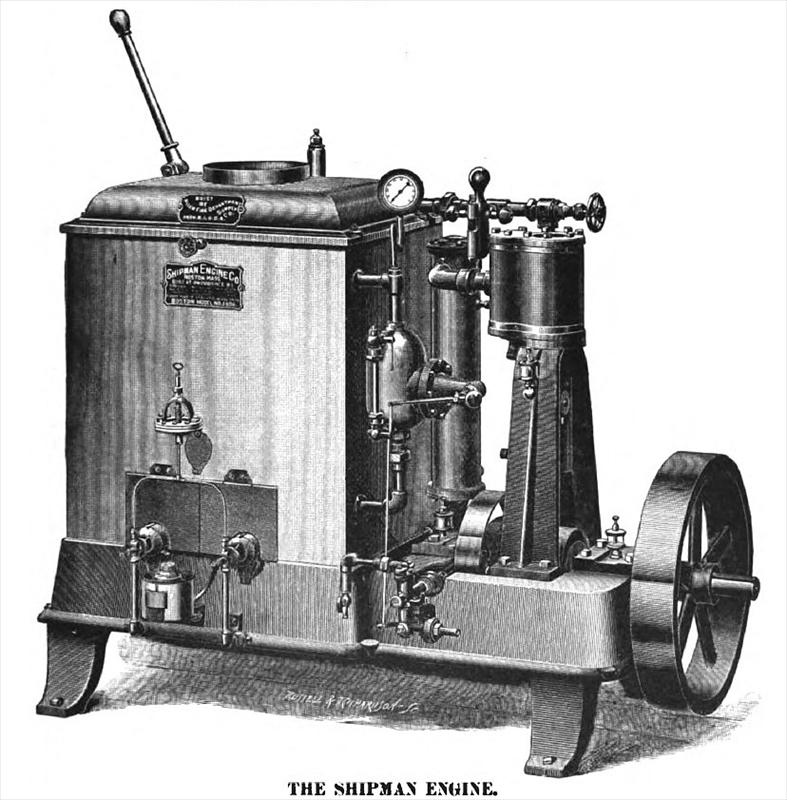

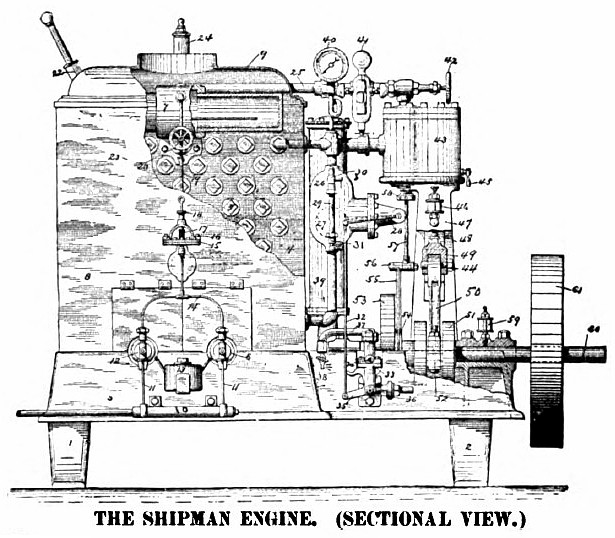

This motor is an automatic petroleum-burning steam-engine, and has been designed by Mr. Shipman, of America, for use either on launches or in houses where a moderate amount of power is required. One of its essential points is that it is automatic, so that when once steam has been generated in the boiler, practically no further attention is required beyond that of opening and shutting the steam-valve whenever the engine is started or stopped, the fire, speed, and water feed being so arranged as to attend to themselves.

The engine is simple or compound, as may be best suited to the work it has to perform, and is built upon the same frame as the boiler. This latter is composed of tubes about eighteen inches long, which are screwed into a flat, oblong chamber at one end and closed at the other, and is fired externally.

Two small aspirators, or atomizers, taking steam from the boiler, suck up the petroleum, which is used as fuel, from a chamber below, and drive it into the furnaces in the form of a fine spray. A couple of torches ignite this spray as it passes inward, and the flames produced by its combustion rush round and among the boiler tubes. The amount of steam and petroleum that is used by the atomizers is regulated by a diaphragm connected to a valve in the steam-pipe that supplies them.

This diaphragm is exposed to the steam pressure on the one side, and is held down by a spring, loaded to a certain pressure, on the other, and moves upward or downward as the steam exerts more pressure than the spring, or vice versa. Its movement is conveyed to the valve by means of a rod, and it thus regulates the amount of steam passing at any moment to the atomizers. In this way the fire is made to vary inversely as the pressure in the boiler, and thus keeps the latter constant.

The petroleum is stored in a tank at any convenient distance from the motor, and is led to it through a pipe having a regulating valve in it. The water in the boiler is kept at a constant level by means of a float, connected to a tap in the suction-pipe of the pump. This float is placed in a chamber, which is joined to the top and bottom of the boiler, and rises or falls with the level of the water. The movement is conveyed, through a stuffing-box and by means of levers, to the tap in the suction-pipe, which it opens or closes as the water level changes.

The speed of the engine is kept regular by means of a governor, which works directly on to the eccentric, and the lubricating of all journals, cylinders, and slides is performed by the ordinary sight-feed lubricators and cups, except that of the crank-pin, which is effected by means of a centrifugal oiler attached to the crank-disk. It may be seen from the foregoing that when once steam is up, the fires, the water-supply, the oiling, and the speed of the engine require no further attention. But when first starting a sufficient pressure is required in the boiler to work the atomizers, and for this a hand air pump is provided. A few strokes of this pump will suffice to start the fires, and it is only necessary to pump slowly for five minutes to raise sufficient pressure of steam to keep them going, fifteen minutes in all being required to get steam up to one hundred pounds per square inch.

As regards the other requirements of small motors, the Shipman Engine is compact, not heavy, and simple to understand, so that it neither requires much space, strong foundations, nor a skilled attendant. (Manufactured by the Shipman Eugiue Co., Boston, Mass.) |

|

1890 Shipman Engine Mfg. Co., Shipman Steam Engine

1890 Shipman Engine Mfg. Co., Shipman Steam Engine

1890 Shipman Engine Mfg. Co., Shipman Steam Engine (Sectional View)

1890 Shipman Engine Mfg. Co., Shipman Steam Engine (Sectional View)

|

|