|

Title: |

1890 Article-Phœnix Iron Works Co., Dick & Church Steam Engines |

|

Source: |

The Steam User 1890 pgs 98-101 |

|

Insert Date: |

4/20/2011 2:29:17 PM |

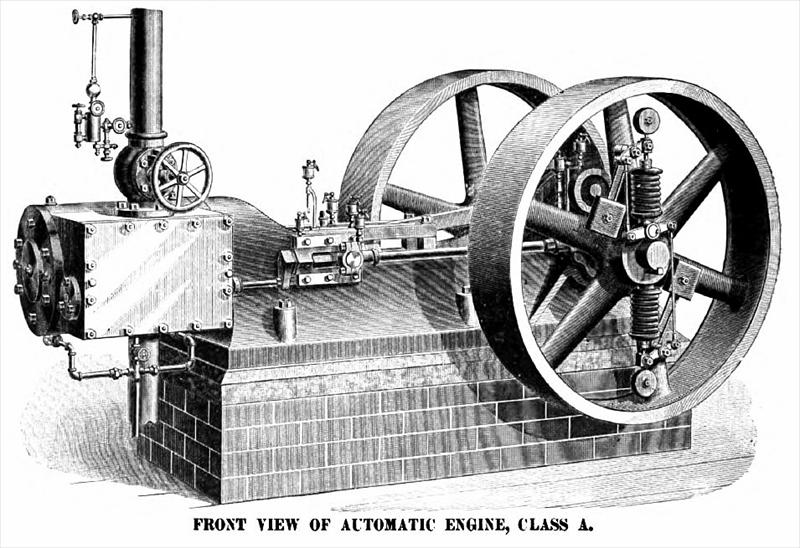

The engraving on page 100 represents a Dick & Church High-Speed Automatic Engine, Class A, of the single-valve type, and possesses some features that will commend it to the attention of those interested in steam-engines and in steam engineering. The bed is of the general form quite commonly adopted for engines with overhanging cylinders, and which, from the speed likely to be adopted, require a firm support on the foundation, as well as rigidity. It is a solid, substantial casting, with plenty of metal where required. The forward end of the bed forms one of the cylinder heads, or covers, without the interposition of a loose piece.

A feature of the bed is the arrangement for taking care of the oil escaping from the rubbing surfaces. The bottom interior surface of the bed, below the slides, is inclined towards the crank end, where the shape adopted forms a reservoir of considerable size. Into this reservoir the waste oil from the slides, the cross-head-pin, crank-pin, and from the inside of the main journals readily finds its way. To the outside of the bed, under the main boxes, are small pockets, into which drips the oil escaping from the outside of these boxes. From these pockets connections are made with the principal reservoir, previously referred to, by means of small pipes placed in the mold and cast in. Thus provision is made for gathering all the oil drip in the principal reservoir, from which it can be drawn by means of a cock provided. This tends to keep the surroundings clean, and provides for saying the oil for future use, with little time and trouble. A depression at the cylinder end of the bed catches the water drip, keeping it separated from the oil. Altogether, the construction of the bed for taking care of the drip is equal to anything we have seen.

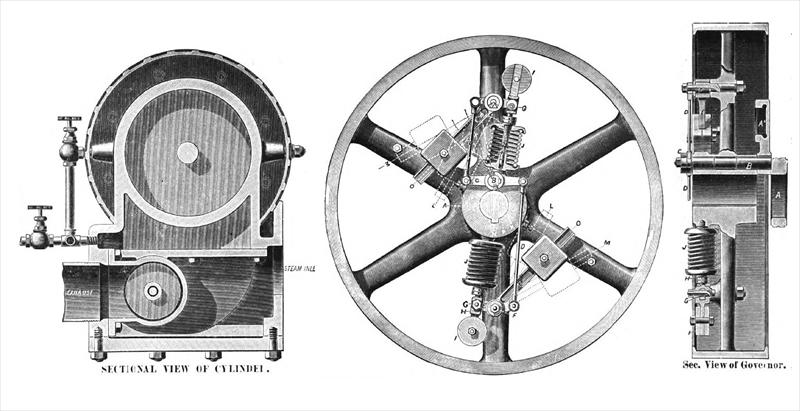

The valve, as will be seen by referring to detail sectional cuts, is of the piston type. It is fitted in a removable case, provided with the necessary steam passages to the cylinder, and exhaust passage to correspond with the exhaust outlet at the bottom of the steam-chest. It will be seen that the case for the valve is surrounded by steam in the steam-chest, so as to ensure equal expansion. The exhaust steam is taken directly away from the cylinder, instead of being kept in contact with any part of the outside of it, the part of the cylinder that would otherwise be jacketed with exhaust steam being exposed to live steam in the steam chest. The admission of steam being by the outer edges of the valve, avoids, when first admitting steam, the possibility of expanding the valve before the case, which sometimes causes serious trouble. No packing-rings are used in the valve, but it is obvious that, for repairs, for instance, such rings could be employed. Considering, however, the fact that the valve and case can be renewed very quickly, and at little expense, and that the absolute balance of the valve almost literally prevents wear, packing-rings are of doubtful economy.

The valve is situated below the centre of the cylinder sufficiently to permit the ports to enter the latter at the bottom or lowest points, thus effectually removing the water of condensation during exhaust. The cylinder is protected against radiation by an asbestos jacket, covered with metal staves, tastefully finished.

The main piston of the engine is deep, and is packed by the use of two sprung rings tongued together at the joint. These rings are made so wide that they cannot by any possibility catch in the ports. They are accurately fitted to the sides of the grooves, and are finished to fit the cylinder while sprung to size.

The construction and operation of the governor are quite clearly shown in the cut. It is of simple design, and, as will be seen, is all situated outside the balance-wheel, and is hence easily come at for inspection. The governor, by means of the cross-shaft passing through the hub of the fly-wheel outside the main centre, operates to shift the eccentric across the shaft, thus varying the throw and the point of cut-off. The governor weights are unusually light, requiring but little force to overcome their inertia, making a very quick acting

and sensitive governor, and giving very close regulation. It will be observed that the springs which resist the centrifugal force of the weights do so under compression instead of extension. Friction is reduced by introducing a knife edge joint at the principal centre of motion. The eccentric is counterbalanced, as will be seen by reference to the sectional cut.

All reciprocating parts of the engine are accurately balanced.

In addition to the regular means of lubrication, the main journal-caps are provided with covered chambers for tallow or other dense lubricant, that will melt should the oil cups fail to feed. For oiling the crank-pin a hole is drilled through it longitudinally, other holes being drilled from the periphery of the pin to connect with this hole. An oil-cup is mounted on the pillow-block caps at each end of the pin. The cups are adjusted to feed regularly, and a metallic "cat's-paw" wipes off the drop of oil and receives it in a-pocket, whence it is carried by centrifugal force to the outside of the surface of the pin.

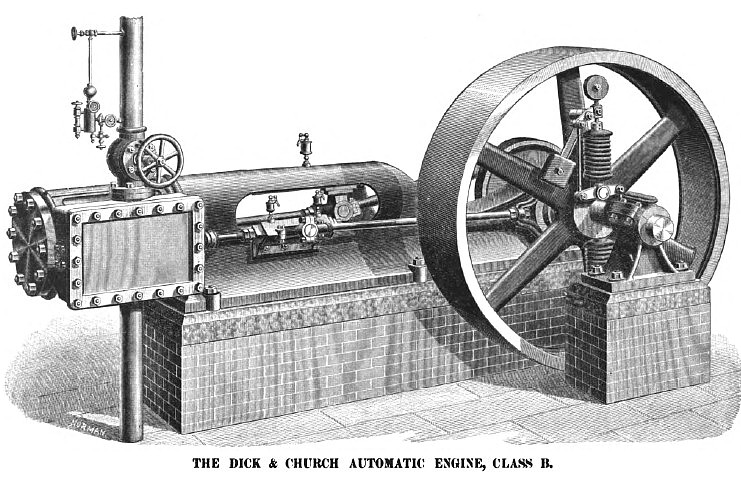

These engines are excellently made, well finished, and of neat design. The cut on page 98 represents the Dick & Church Automatic Engine, Class B, which is designed for moderate speeds. There are a great many of these engines in operation, and their reputation is fully established as being one of the leading engines of this country, are made by the Phœnix Iron Works Co., Meadville, Pa. |

|

1890 Phœnix Iron Works Co., Dick & Church Steam Engine, Class B

1890 Phœnix Iron Works Co., Dick & Church Steam Engine, Class B

1890 Phœnix Iron Works Co., Dick & Church Steam Engine, Class A

1890 Phœnix Iron Works Co., Dick & Church Steam Engine, Class A

1890 Phœnix Iron Works Co., Dick & Church Steam Engine Cylinder & Governor

1890 Phœnix Iron Works Co., Dick & Church Steam Engine Cylinder & Governor

|

|