|

Title: |

1890-Article Weston Engine Co., Automatic Steam Engine |

|

Source: |

The Steam User 1890 pgs 74-75 |

|

Insert Date: |

4/19/2011 5:08:39 PM |

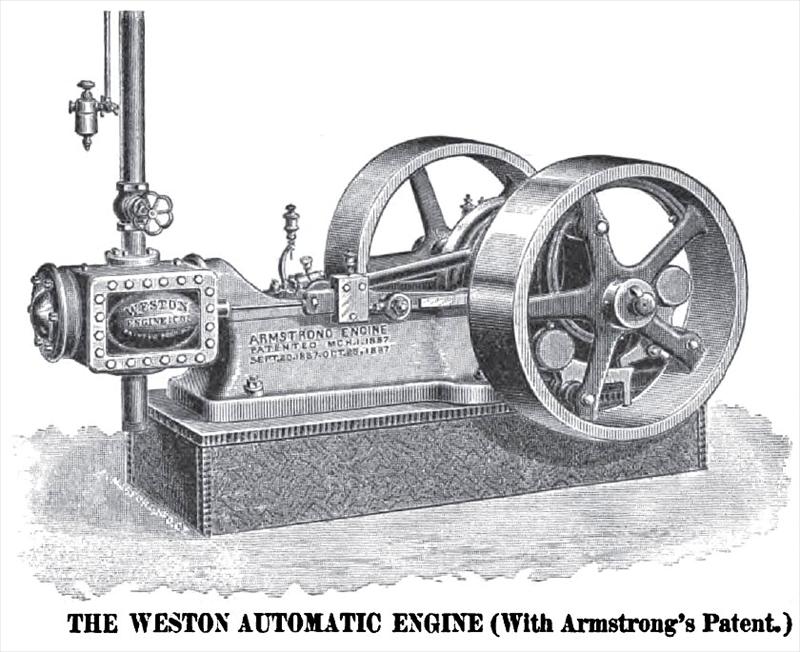

The manufacturers of the Weston Automatic Engine frankly state that a single-valve engine is not as economic as a well-built Corliss Engine, but the difference, they say, is, in a seventy-five horse-power engine, more than overbalanced by the considerations which are responsible for the existence of the modern single valve automatic— low first cost, high speed, and limited amount of room.

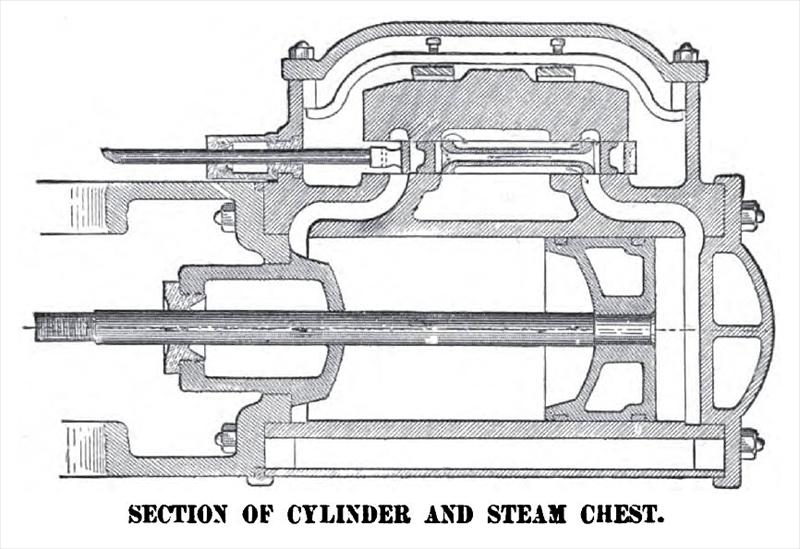

The cylinder and steam-chest are shown in section on opposite page. These cylinders are cast from a strong mixture of charcoal iron, which is mixed in the cupola, poured into pigs, and remelted to refine it. The cylinder, steam-chest, and jacket are cast in one piece; a construction giving great stiffness and facilitating accurate boring. The ports are very large, short and direct, and the valve-seat is brought as near the cylinder as possible.

The valve is a single casting with accurately parallel faces, and works steam tight between its seat and a heavy pressure-plate; the steam, being admitted to the centre port, acts in a direction to lift the pressure-plate away from the valve, which it is prevented from doing by springs, strained to hold a steam pressure somewhat greater than is ever likely to be brought upon it. This does not prevent the valve lifting, to relieve the cylinder of water, in the same manner as an ordinary slide-valve. This valve acts in a manner clearly shown in the cut, to give four openings for admission, the length of each equaling the diameter of the cylinder; this ample ports, gives, as might be expected, a high steam line and a sharp cut-off. The exhaust is through a double opening, and is not fairly represented by the accompanying cards; they have been taken from an engine exhausting through heating coils in a dry kiln. This form of valve when properly fitted up will keep tight for a long time, acquiring a beautiful polish, and working without appreciable friction. Wearing down by its own weight does not open a leak, as in a piston-valve, and when after long use leakage does occur it is readily taken up by the adjustable distance-pieces which support the pressure-plate. The live steam being admitted under the valve and exhausted into the steam-chest, permits the steam-chest cover to be removed and the valve examined under steam pressure—a feature which, with the adjustable distance-pieces, provides for long continued tightness. The stuffing-boxes of high-speed engines are often a source of considerable trouble, which in this engine has been reduced to a minimum. The valve stem is packed only against exhaust steam, and will run indefinitely without repacking. The piston-rod stuffing-box, as shown in the section of the cylinder, is of novel design and equally novel behavior. Fibrous packing as used in the average stuffing-box must, by reason of the small space reserved for it, be compressed until it is about as hard and inelastic as a piece of wood. In this box there is a large amount of packing which can not be very tightly compressed, and, if properly packed, the steam pressing on the packing follows up the wear and obviates any necessity for adjustment of the gland. These engines have been run without leaking for over a year, without repacking or even adjustment of the gland—a result which is very unusual. The cross-head is new, and possesses the somewhat unusual feature of going together in correct alignment The "shaft governor" is of very simple construction, consisting of the eccentric, two fly weights, a flat spring, and a few pins and bolts for connecting the parts together. All strains are constant in the same direction, thus preventing lost motion from wear. There is no difficulty in adjusting the governor to a variation in speed of considerably less than one per cent, light or loaded; but they prefer, where permissible, a somewhat greater range, say one and one-half or two per cent, as giving greater stability and less wear.

The oiling devices are very complete, every bearing being oiled from stationary sight-feed oil cups, and also being capable of being oiled from a common oil can while in full motion. The oil wasting from the boxes is caught and carried to the crank pin and eccentric; oil flying from the crank is caught in oil boxes and held until the engine stops. The bearings are generous enough to satisfy the most radical advocate of large wearing surfaces; they are finely fitted, and proved in the testing room by being run at high speed and heavily loaded until they will work to double their rated power without showing any tendency to heat or pound. The interchangeability of the parts of these engines forms a valuable feature, as break-downs do sometimes occur in the best regulated engine rooms, and if parts will fit exactly much expense is saved. (Manufactured by the "Weston Engine Co., Painted Post, New York.) |

|

1890 Weston Engine Co., Automatic Steam Engine

1890 Weston Engine Co., Automatic Steam Engine

1890 Weston Engine Co., Automatic Steam Engine (Section)

1890 Weston Engine Co., Automatic Steam Engine (Section)

|

|