|

Title: |

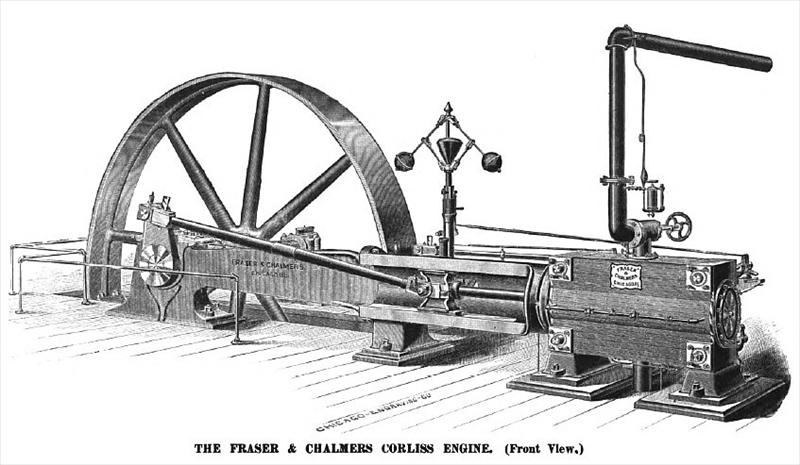

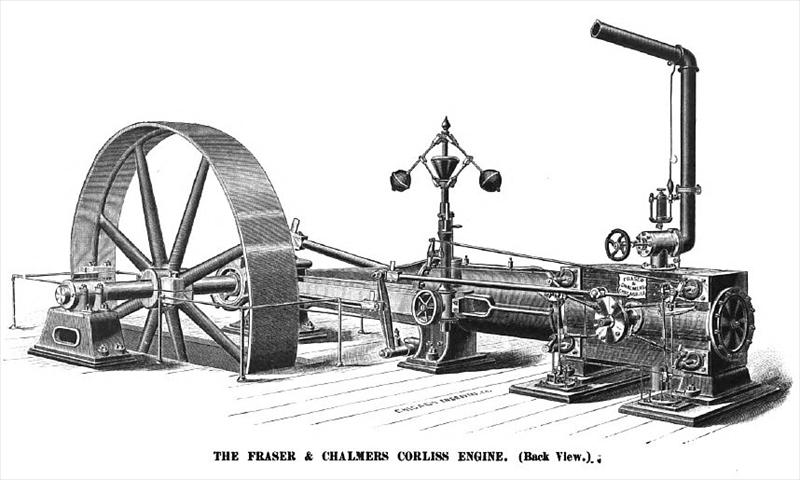

1890 Article-Fraser & Chalmers Co., Corliss Steam Engine |

|

Source: |

The Steam User 1890 pgs 70-73 |

|

Insert Date: |

4/18/2011 2:21:45 PM |

The illustration opposite shows the back view of the Fraser & Chalmers Corliss Engine. Like all Corliss engines, the valves are four in number, consisting of two steam and two exhaust, each with liberal wearing surfaces.

The connecting-rod is forged from a good quality of selected scrap iron, turned and finished all over. Both ends provided with brass boxes, with suitable means for adjustment. The piston rod, of ample proportion, is made of steel turned true, and finished by draw-filing.

The engine crank, which is cast from the same mixture of iron used in cylinder, as previously described, is faced on both sides, one side working against the end of main bearing, the other being even with end of shaft when in place. The cranks are in every instance forced on the shaft under a hydraulic pressure of many tons. After being forced home against the shoulder on shaft, they are keyed on by means of a properly fitted steel key, this operation being of great importance, as it is essential that a perfect fit be made to prevent the crank from working loose after the engine has been put in operation. Skilled mechanics realize the necessity of this being properly done.

The crank pin is forged from mild steel and turned perfectly true» when forced, under a heavy pressure, into crank, it is riveted to place, thus insuring against the pin ever becoming loose. The hole in crank to receive pin is carefully bored out parallel with the bore for crankshaft. The result is a smooth-running engine, without the annoyance of hot boxes present in so many instances when engines are first started, and which difficulty, if owing to a crooked crank pin, can only be overcome by removing the pin, reboring, and inserting a new crank pin.

The piston is one part of the engine that should receive from the hands of engine builders the utmost consideration. Not only should the metal used be specially adapted for the purpose, but the workmanship and general design be a result of long experience and much careful study. A properly constructed piston should combine lightness and strength as well as simplicity. In constructing the piston which has been used on our engines for many years we have endeavored to overcome the objection found in this important part by engineers and steam users in general, some of whom may remember to their sorrow the apology for a piston in the shape of a solid disc, or an impracticable substitute that has been forced upon them in inferior engines, with which it was their misfortune to be acquainted.

The main pillow block is especially designed to resist the severe strain brought to bear upon it during the time occupied in making a revolution of engine shaft. The greatest strain is occasioned when the steam valve commences to open, admitting steam to either end of cylinder. To overcome the attendant pressure at this point, a sufficient quantity of metal has been located in a careful manner, which precludes any danger or springing of parts when the engine is working to its utmost capacity.

The lower removable box in which engine shaft sits is lined with a composition metal specially adapted for heavy work. The side or quarter boxes are also lined with the same material, and are adjustable by means of a taper wedge, controlled and operated by bolts running through the cover of pillow block, and secured by jam nuts. The inside cap which rests on either quarter box, holding them with the assistance of the main cover rigidly in place, should not come nearer than 1-16 inch to the top of journal when engine is in motion. The aim being merely to hold the side boxes solidly in position when once set. The top and bottom as well as the side boxes are bored when in pillow block, after being carefully fitted and marked to place.

The crank shaft is forged from the best quality selected scrap iron, turned full length, nicely finished, and key-seated a proper distance between journals to receive the band or fly-wheel, which after being set in place is held in position by means of a carefully fitted steel key. A suitable collar is forced on shaft, which, coming in contact with the side of main bearing, prevents any side play in that direction. The engine crank prevents lateral movement in the opposite direction, except what is absolutely necessary to prevent the heating of boxes.

The cross-head, one of the most important of all parts connected with the construction of a steam engine, has received our careful consideration. The design which we have adopted for this part is neat and combines strength and lightness.

The cast steel cross-head is used exclusively on their Corliss engines. The advantage is in a less weight of metal to travel on the guides, which reduces the friction, as well as a less weight in moving parts to overcome after the engine has passed the centre, and is beginning another stroke. The top and bottom of the cross-he d is provided with adjustable brass gibs lined with a composition metal of excellent wearing qualities.

The steam cylinder is one of the principal as well as most expensive parts of an engine. It is necessary that it be made from an iron possessing hardness, toughness, and an even grain, and at the same time be moulded carefully. The steam cylinder, the important part of an engine, is cast from a mixture of the best refined and Lake Superior brands of charcoal iron. The result of this combination is an iron of a dense nature, having qualities susceptible to a high finish and possessing lasting wearing surfaces. Some cylinders, as a rule, do not exhibit the same amount of wear at every part of stroke after they have been in use for a certain length of time. Some are found that show greatest amount of wear at one end, some at other, while still others show a larger amount at mid-stroke. Their opinion, based upon long experience, is that many of these difficulties arise from an improper mixture of iron from which the casting was made. Of course, we at the same time admit that other causes may be present which influence more or less wear to one part than another; an engines may be out of line, one improperly packed, or one wherein the piston rings were adjusted carelessly; all have tendencies to cause uneven wear of the cylinder. The cylinders of the Fraser & Chalmers engine are provided with suitable pipes and valves for attaching indicator to either end of cylinder.

This firm also build Corliss Horizontal, Vertical, Twin and Tandem Compound, Condensing and Blowing Engines with air compressors.

(These engines are manufactured by Fraser & Chalmers, Chicago, Ill. |

|

1890 Fraser & Chalmers Co., Corliss Steam Engine (Front View)

1890 Fraser & Chalmers Co., Corliss Steam Engine (Front View)

1890 Fraser & Chalmers Co., Corliss Steam Engine (Back View)

1890 Fraser & Chalmers Co., Corliss Steam Engine (Back View)

|

|