|

Title: |

1890 Article-Westinghouse Machine Co., Junior Steam Engine |

|

Source: |

The Steam User 1890 pgs 40-45 |

|

Insert Date: |

4/16/2011 1:53:40 PM |

In general form the Westinghouse Compound Engine more nearly resembles the Junior Engine, which is illustrated and described in the following pages. The mechanical characteristics of the single acting engine are retained in every particular. One cylinder is enlarged to practically 3 ½ times the area of the other. The valve chest is across the top of the cylinders, being the construction, which admits of the least possible clearance in the 1. p. cylinder. The valve chest is in one piece, the various steam passages being chambered in it. The valve seat is in the form of a bush, in which the ports are cut— not cast—to an exact register. This bushing is reamed out and forced steam-tight into its bored seat. This form of construction has many advantages. The casting is greatly simplified, avoiding all chance of porousness, sand holes, and other defects, which are liable to cause concealed leaks. The valve seat can be made perfect, and the parts registered exactly, on which latter fact depends the perfection of the steam distribution and the consequent economy of the engine. And lastly the valve seat can be easily and cheaply renewed when worn. The engraving on opposite page shows the working parts so clearly that an explanation is hardly necessary. The valves are perfectly balanced, and the steam ports are very direct and large, having an area of over 12 per cent, of the area of the piston. The exhaust openings are also large, to avoid back pressure. The balance of the reciprocating parts is secured in a very simple manner. The reciprocating parts of each cylinder are exact duplicates of each other as to weight and extent of motion. The two cranks being opposite each other instead of quartering, all the masses of each side are at all times moving in exactly opposite directions and with equal velocities. Hence each precisely counteracts the effect of the other, whatever the speed, so that the balance is attained without complexity or multiplication of parts. The fact that the two pistons work side by side, and not in the same plane, leaves a slight unbalanced effect in a direction parallel to the shaft only, which is adequately provided for in the length of base.

The most important feature of the Westinghouse type is constant direction of strains, sad is peculiar to this Engine. It is well understood that with the ordinary forms of double-acting engines the direction and nature of all of the strains are changed twice in each revolution from compression to extension, and vice versa, as the steam is alternately admitted to each side of the piston. Hence the necessity for elaborate means for taking up lost motion at every joint, and hence also the still more pressing necessity for an engineer who may be trusted to so make the adjustments as to avoid heating on the one hand and pounding on the other. Hence the necessity and beauty of the single-acting principle. With it all parts are subjected at all times to compression only; hence, no matter how much lost motion exists, it is always taken up by the pressure of the steam acting constantly in one direction. The weight of the parts also acts with the steam pressure to assist the same result. Indeed, it is quite possible to run one of these engines with the lower half of the crank-pin box removed. The practical results are freedom from pounding or noise of any sort; and the practicability of continuous running.

Among the other excellent features possessed by the Westinghouse Engine is its method of lubrication is perhaps the most valuable. The valve and pistons are lubricated in the usual way by an automatic lubricator discharging into the steam pipe. The governor and all the other running bearings are contained within the enclosed chamber of the crank-case. This case is filled, as shown in the sectional views, to near the bottom of the shaft with water, on which is floated a certain quantity of oil. Into this the cranks and eccentric dip at every revolution, and it may readily be believed that when running to speed the entire chamber of the crank-case and cylinders is filled with a foam of oil and water, which is bound to reach every part. Moreover, ample lubrication is provided =for the main bearings by the ojl which

finds its way out past them, further ensured by using the oil cups on them as the point of introduction of all the oil for the engine. Any excess is caught by the ring wipers and returned into the crankcase. Besides its great cleanliness this method of lubrication is very economic, since the oil is used over and over, and no more is needed than what is given to the main bearings.

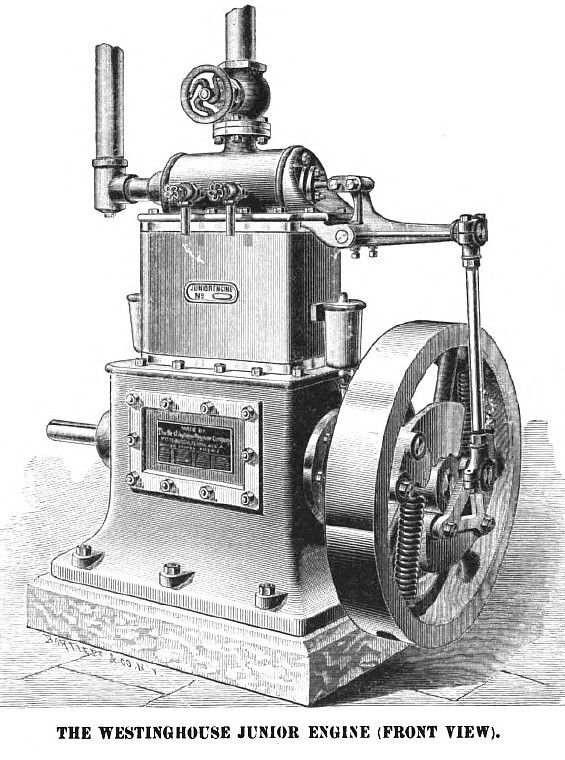

In the construction and design of the "Standard " and Compound engines the considerations of cost have given way to valid improvements, but to meet the demand for a low-price automatic engine the "Junior" type was designed.

Mechanically, the Junior Engine retains the distinctive and vital characteristics of the Westinghouse Standard Engine, namely: self-contained, single-acting, automatic governing, and, to a large extent, self-lubricating. The valve is driven from a wrist-pin in the governor instead of from an eccentric. This automatic governor is exceptionally good and sensitive. Its lubrication is as good as can be obtained in the usual forms of outside-connected governors. Any engine in the hands of the most competent engineer may meet with an accident, or need repairs of some kind. But the system adopted by the Westinghouse Company, of giving with each engine a list showing every detail, illustrating each separate piece, however small, and giving its name, weight, material, and price f. o. b. Pittsburgh, Pa, and a cipher word for ordering repairs by wire saves much delay.

(These engines are manufactured by the Westinghouse Machine Co., Pittsburgh, Pa.) |

|

1890 Westinghouse Machine Co., Junior Steam Engine

1890 Westinghouse Machine Co., Junior Steam Engine

|

|