|

Title: |

1890 Article-Hewes & Phillips, Tandem Compound Steam Engine |

|

Source: |

The Steam User 1890 pg 26-29 |

|

Insert Date: |

5/3/2019 10:50:40 AM |

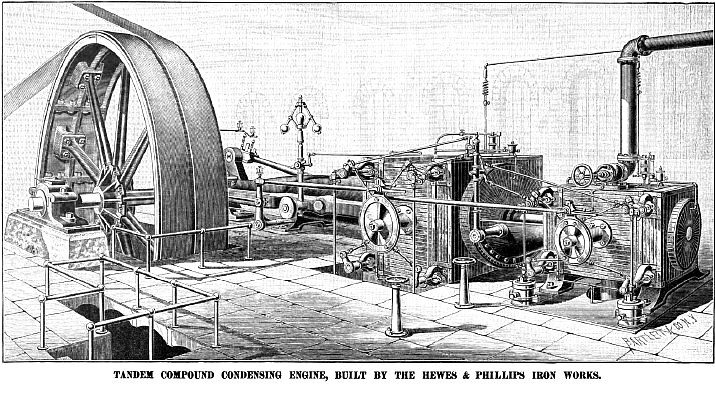

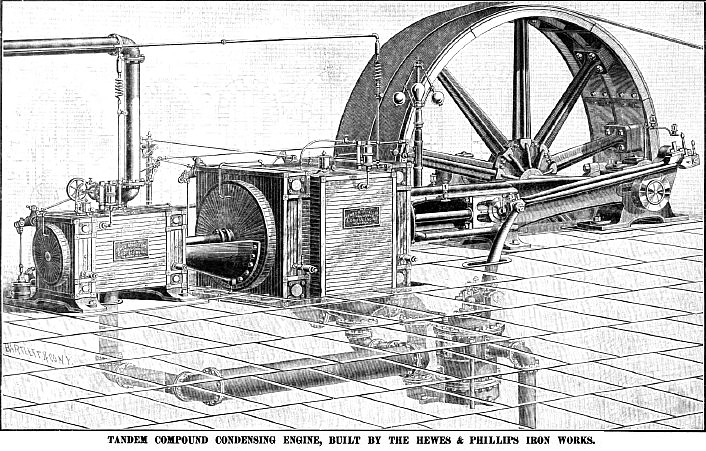

The illustration on the opposite page represents a tandem compound condensing engine recently built at the Hewes & Phillips Iron Works, Newark, N. J. The great aim in the design of this engine is to secure a maximum economy of fuel; also a comparatively uniform speed, not only throughout one revolution of the crank, but through every period of time; great care has also been taken to isolate the cold exhaust from hot "live steam." The steam cylinder, as well as the heads, is thoroughly steam jacketed; and the water, due to condensation in the jackets, is returned by means of a suitable jacket pump into the boilers. This jacket pump, the air-pump, condenser, and a system of piping, are all placed underneath the floor, as shown in the illustration. The steam from the high-pressure cylinder is conducted through a portion of this system of piping directly into the low-pressure cylinder; no receiver between the two cylinders is used. From the low-pressure cylinder the steam is conducted into the upright jet condenser, shown at the left-hand side of the air-pump, and thence the air-pump takes the water, and allows it to flow into the sewer. In this particular engine salt water is used for condensation, and therefore none of the water due to the condensation of steam from the cylinders is returned into the boilers.

The air-pump is worked from a lever and return rod from the crank; part of this lever is shown above the floor. The small jacket pump is placed on top of the air-pump, or, we should say, on top of the hot well, and is worked from the same lever. The cylinders are 22 and 44 inches diameter, by 48 inches stroke; the low-pressure cylinder is made to stand 50 pounds initial pressure. The throttle-valve on high-pressure cylinder is 8 inches diameter. The bed and pillow block are tied together with inch iron bands, shrunk on. The pillow block bearing inches diameter, and 26 inches long; shaft, 15 inches diameter; crank-pin, 8 inches diameter and 8 inches long; air-pump, single acting, 32 inches bore by 12 inches stroke; the fly-wheel, 24 feet diameter and 60 inches face; weight, 58,000 pounds. The hub is made in two pieces, pressed on to and keyed fast to the shaft; the rim is made in ten segments.

The valve gear is of the Corliss type. The clearance spaces between the valves and cylinder are very short and direct; the valves have long supports, or bearings, at each end. The steam enters the cylinders at the inner edge of the port toward the throttle-valve. In adopting this method, too abrupt angles in the steam current are avoided; the result is that the steam admission is practically perfect. No springs are used for holding the steam or exhaust valves to their seats; this result is obtained by taking advantage of the steam pressure and the weight of the valves. These valves are, like all Corliss valves, which are properly designed and fitted up, practically balanced, so that they can be operated by hand with the throttle open. In all engines made by this firm, the valves can be removed from the cylinder for examination, and replaced, without the removal of any part of the releasing gear. All the mechanism of the releasing gear moves about a common centre, which is the centre of the valve stem ; this makes the leverage of detaching or releasing a constant quantity.

The steam valves are closed by a vacuum dash-pot of improved design. It works very quietly, and gives the steam valves a rapid movement in closing; the valves cross the port edges at a maximum velocity. Several very simple attachments are made to this dash-pot, so that its action can be easily and thoroughly controlled.

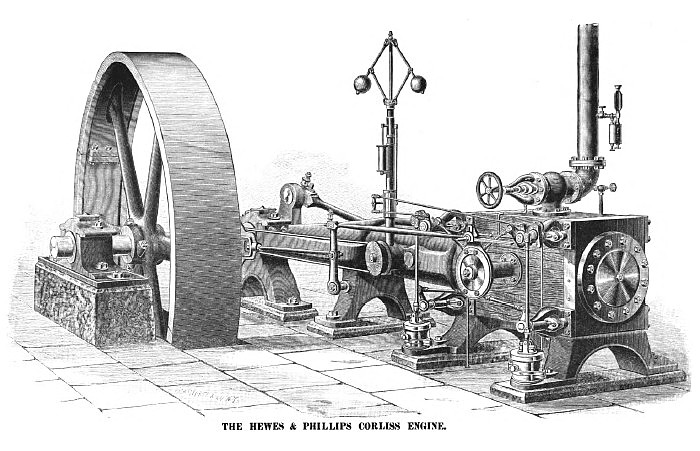

This firm builds, besides the tandem compound type of engine, another one, which they name the "Cross-compound."

On the next page will be found another view of this engine, and on the page following an illustration of their Corliss engine.

US Patent: 378,105

http://datamp.org/patents/displayPatent.php?number=378105&typeCode=0 |

|

1890 Hewes & Phillips, Tandem Compound Steam Engine

1890 Hewes & Phillips, Tandem Compound Steam Engine

1890 Hewes & Phillips, Tandem Compound Steam Engine

1890 Hewes & Phillips, Tandem Compound Steam Engine

1890 Hewes & Phillips, Corliss Steam Engine

1890 Hewes & Phillips, Corliss Steam Engine

|

|