|

Title: |

1890 Article-Fitchburg Steam Engine Co, Steam Engine |

|

Source: |

The Steam User 1890 pg 8 |

|

Insert Date: |

4/13/2011 3:20:08 PM |

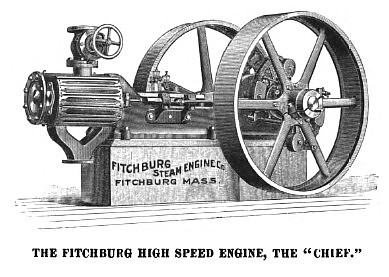

FITCHBURG ENGINES FOR ELECTRIC LIGHTING.

The upper engraving illustrates the Fitchburg automatic high-speed engine for electric lighting. This engine is particularly adapted to this work, as it is absolute in regulation and can be run at a high rate of speed. In constructive detail the machine is considered of superior workmanship. The main bed or frame is very stiff and rigid, having ample resistance in the line of strains, large cross-head bearing surfaces, and large and long shaft bearings. The connecting-rod boxes are hard composition, and with the hardened steel pins are practically indestructible. All bearings are made for ready adjustment, and all parts are made interchangeable.

The valve in these, and also in the low-speed engines, is so constructed as to be readily adjustable diametrically to compensate for the slight wear resulting from the action of gravity, which otherwise would cause serious waste in time because of leakage of steam, or would require a periodical replacement of valve. The cylinder is designed for ample admission of steam, the clearance being as small as is consistent with the best steam distribution, and being filled at each stroke by compression to nearly boiler pressure, thus utilizing the otherwise wasted momentum of the reciprocating parts, and by this cushioning relieving the engine of the usual jar and hammering of high-speed engines when passing centres. The valve-rod is guided in a slide lined with anti-friction metal, ensuring an absolutely rectilinear movement, with no tendency to such cramping strains as come from the arc described by a rocker arm, which are especially injurious where the piston-valve is used.

The piston-valve which is used is absolutely balanced, and therefore does not appropriate any of the indicated power in actuating itself.

In trying to get the good results which come from a readily adjustable diameter, as described above, some of those who use the piston valve put in "removable linings" which, it is claimed, can be taken out and new linings, fitting new valves, be pressed into their places and the valves be properly tight. "Were this a fact the expense and trouble is such that it is not done by owners of such engines until very decided leak has made it absolutely necessary, meanwhile wasting perhaps hundreds of dollars' worth of fuel.

The principal wear upon any piston-valve comes in the first six months' use, while it is getting a perfect seat. If it can then be adjusted to tightness it need be looked at but once a year thereafter. A solid valve, even with "removable linings," cannot be adjusted, and must either be replaced every six months, or gain in leakage more and more rapidly, because of the cutting action of escaping steam.

An hour's time of the engineer will adjust these valves, and they can be thus kept tight during the life of the engine without expense. This is an item of immense value in an engine.

The Automatic Governor is a part of one of the pulleys, and is keyed to the shaft, being very simple and having no large friction surfaces to be moved upon each other when the load is changed, but simply four brass bushings moving upon steel pins and turning about 1/20 of the circle only in changing the point of cut-off from 1/32 to 1/2 stroke, or from no load to full load of the engine. These bearing points being hard brass upon steel, there is no sticking even if oil is not properly supplied to them, as is the case where large cast-iron surfaces are to be moved upon each other, or upon the shaft. There is also covered by patent the principle of balancing in a centrifugal shaft governor the weight of eccentric block, strap, and rod, relieving the working parts of all duty except that of changing the position of eccentric when the load changes, one of the elements entering into the closeness of regulation without jerk or vibration.

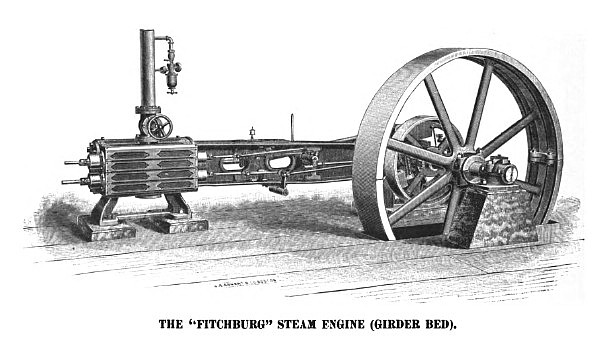

The lower engraving on the opposite page represents the "Fitchburg" low-speed engine, which is built in sizes from 20 to 500 horsepower.

In these low-speed engines, as will be seen by the cut, the I form of girder frame is used, which gives for a stated amount of iron the strongest possible form to resist lateral and twisting strains. The vertical central rib is brought as close to the cross-head as will allow the latter to pass freely, getting the full benefit from it in resistance of vertical strains, and the guides are bored from the centre line of cylinder by a special boring machine made for the purpose, having a reciprocating rocking motion instead of complete revolution, the latter of which would be impossible, because of the closeness of the central rib, as described. This makes it possible to get the large benefits of the bored guides, together with the stiffness of the rib close to centre-line of strain.

The steam valves are double ported, the equivalent of a four-ported gridiron valve, and are actuated through a simple wrist-plate by an eccentric, the relative location of which upon the shaft is fixed by the governor, which is firmly held upon the shaft by clamping bolts and set-screw, and which permits an automatic range of cut-off from one sixteenth to two-thirds stroke.

(These engines are made by the Fitchburg Steam-Engine Company, Fitchburg, Mass.) |

|

1890 Fitchburg Steam Engine Co, Steam Engine (Girder Bed)

1890 Fitchburg Steam Engine Co, Steam Engine (Girder Bed)

1890 Fitchburg Steam Engine Co, Steam Engine, the "Chief"

1890 Fitchburg Steam Engine Co, Steam Engine, the "Chief"

|

|