|

Title: |

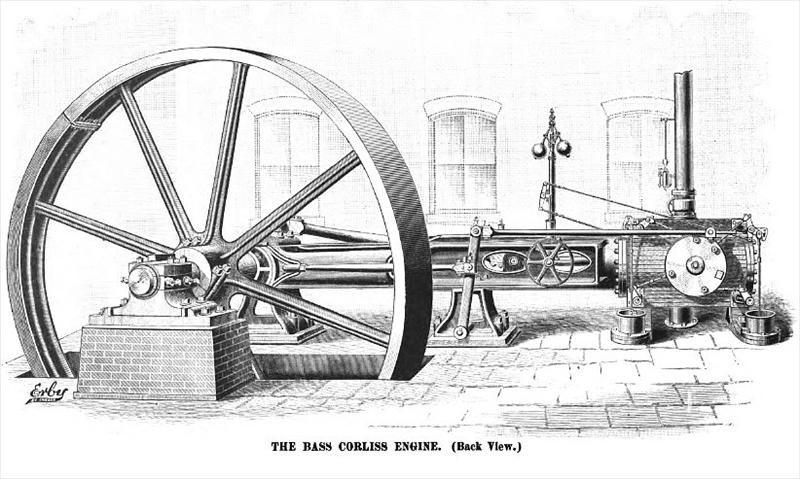

1890 Article-Bass Foundry & Machine Co., Corliss Steam Engine |

|

Source: |

The Steam User 1890 pg xliv |

|

Insert Date: |

4/5/2011 12:30:25 PM |

The valve gear of the Bass-Corliss Engine is one of its most important features. To use steam economically it is absolutely essential that it shall enter the cylinder at practically the same pressure as exists in the boiler at the beginning of the piston's stroke, and until this supply is cut off the pressure must be constant. After the cut-off, the stroke is completed by the expansion of the steam which has entered the cylinder. Provided these conditions are carried out, the steam in the cylinder will have completed its usefulness, and must be quickly exhausted, so that there will be no back pressure in the cylinder.

To produce these results, not only must the valve gear be perfectly constructed, but the valves must have large wearing surfaces, as small ones are likely to increase the cutting and wearing of the valve seats. The ports must be of suitable size. The mechanism controlling the cut-off must operate so that the steam port will be quickly opened for the admission of steam, and maintained up to the point of cut-off, and then the port must be quickly, almost instantaneously, closed. The valve gear of the Bass Engine, it is claimed, accomplishes all this.

The valves of this engine are so arranged that no springs are required to keep them in place, and as they are simply cylindrically formed pieces of cast iron, there is nothing to get out of order. As usual, four valves are used, and these valves, consisting of one piece of iron, are all that the steam-chests contain. Any one of them can be easily taken out and examined without destroying the adjustment of the valves are driven by a wrist plate attached to the side of the cylinder.

The valves take up their own wear, although there is little in a Corliss valve. The exhaust valves, from their position, effectually drain all the water from the cylinder.

The valve gear opens the valves, but the prompt closing of them is effected by vacuum dash-pots of improved design, and noiseless.

The frame is of the Girder type, cast without any attempt to spare the metal, and yet not cumbersome-looking. In fact the frame is very symmetrical and artistic in design. Hook releasing gear is used, and most engineers are in favor of this style over the " Crab claw."

The hooks are of steel, and each has eight wearing surfaces, so that when one edge is worn it can be changed to another.

The connecting-rod is made with gib-and-key adjustment, and is of the uniform length of six cranks, from centre to centre.

The Main and Outboard Pillow-Block have large wearing surfaces. The cross-head runs in V-shaped guides, and has vertical alignment.

The Shoes are adjusted by long wedges operated by compensating screws.

The governor is of the fly-ball type of simple form, and very sensitive in its operation.

These engines are manufactured compound and triple expansion, arranged side-by-side or in tandem form. |

|

1890 Bass Foundry & Machine Co., Corliss Steam Engine

1890 Bass Foundry & Machine Co., Corliss Steam Engine

|

|