|

Title: |

1890 Article-E. P. Allis & Co., Reynolds-Corliss Triple Expansion Pumping Engine |

|

Source: |

The Steam User 1890 pg xxiv |

|

Insert Date: |

11/13/2012 1:01:45 PM |

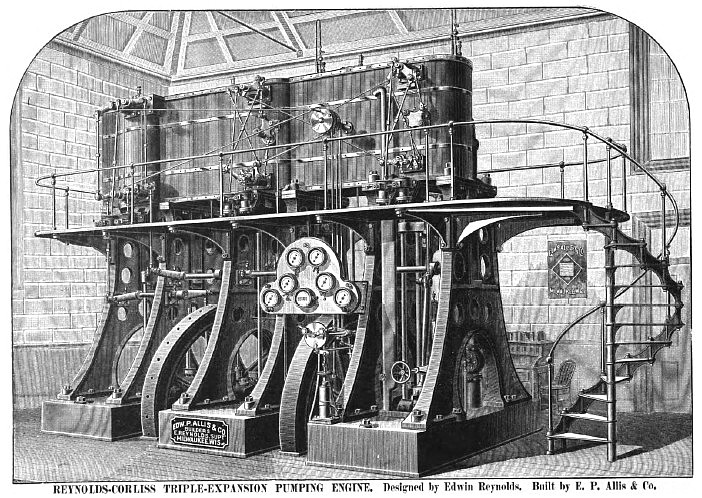

The engraving on the opposite page illustrates the first triple expansion pumping engine constructed in this country, if not in the world. This engine was built for the city of Milwaukee, with a guaranteed capacity to raise 6,000,000 gallons of water 100 feet high every twenty four hours for supplying the high service system of the city.

It represents a three-cylinder Reynolds-Corliss engine, with pump plungers attached below the engine-room floor line. Steam is admitted first to the high pressure cylinder, 20 ½ inches diameter, and from there exhausted into the second or intermediate cylinder, 35 inches diameter; from this cylinder it is exhausted into the low-pressure cylinder, 49 inches diameter; and from this last cylinder to the condenser. The stroke of all the cylinders is uniform—36 inches.

The contract stipulates that it shall have the capacity above mentioned, and develop a duty of 115,000,000 foot pounds of work for every 100 pounds of coal fired to the boilers. The steam cylinders, three in number, are mounted on massive cast iron A frames, which rest on the bed plate below. The pumps are of the plain, outside packed, plunger type; they are amply provided with means for inspecting the valves, and replacing with new when they become worn. The pumps, air chambers, and condenser are all located below the floor line of the engine-room. The Reynolds-Corliss valve gear is employed on the steam cylinders; the steam and exhaust valves are placed in the cylinder heads; by this means the clearance or waste room in the cylinder and ports is reduced to less than l ½ per cent. The inlet and discharge passages in the pumps are made amply large to admit of the free passage of the water, and reduce the unavoidable friction to the lowest possible limit, when the engines are running up to their maximum speed. Convenient stairways and galleries give easy access to the various parts of the engines and pumps. All the steam cylinders, receivers, and cylinder heads are thoroughly steam jacketed, to prevent loss of steam by condensation.

Five engines of this type are now being built for the city of Chicago, each engine to have a capacity of raising 15,000,000 gallons ol water 125 feet high every twenty-four hours; the steam cylinders are as follows:

High pressure cylinder, 24 inches in diameter; intermediate cylinder, 46 inches in diameter; low pressure cylinder, 70 inches in diameter; all cylinders of 60-inch stroke.

And for the city of Albany, New York, four engines, each with a capacity of raising 5,000,000 gallons of water 310 feet high every twenty-four hours; the steam cylinders are as follows:

High pressure cylinder, 26 inches in diameter; intermediate cylinder, 45 inches in diameter; low-pressure cylinder, 64 inches in diameter; all cylinders of 48-inch stroke. |

|

1890 E. P. Allis & Co., Reynolds-Corliss Triple Expansion Pumping Engine

1890 E. P. Allis & Co., Reynolds-Corliss Triple Expansion Pumping Engine

|

|