|

Title: |

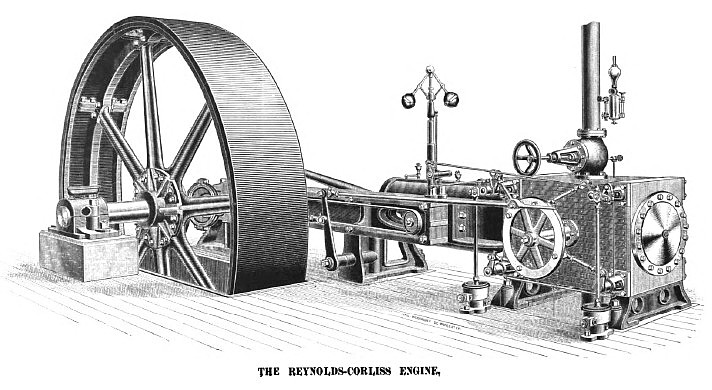

1890 Article-E. P. Allis & Co., Reynolds-Corliss Engine |

|

Source: |

The Steam User 1890 pg xx |

|

Insert Date: |

4/2/2011 7:17:01 PM |

The frame or bed is made in two pieces, which are accurately fitted and securely bolted together—one piece containing the slides and forming the front cylinder-head, the other portion being cast solid with the main pillow-block. The pillow-block is very heavy and strong, having a broad bearing on the foundation, and secured by heavy anchor bolts, same as the cylinder end; it is also provided with effective means for taking up wear in the main journal. At the centre of the bed, and directly under the slides, is another support, which gives additional solidity to the frame, and renders any springing or vibration impossible.

The automatic connections are direct and positive, and although entirely independent of the cut-off valves, as regards holding or driving them, the regulator maintains perfect control of these valves and determines the points of cut-off with unfailing accuracy.

The most distinctive feature of this engine, and from which it derives the name of the "Reynolds" Corliss more particularly than in any other detail is embodied in the design and construction of the valve-gear. The valves themselves have very large wearing surfaces, thus entirely and effectually preventing the cutting and wearing of the valves and valve-seats, which will occur where small wearing surfaces are exposed to continuous pressure and motion. The valves are simple cast-iron blocks of cylindrical form, and are so arranged that they require no springs to hold them in place; they rest in their seats perfectly free to move, and entirely unhampered by yokes or other contrivances; they are driven from one end by simple T heads, formed on the inner ends of the valve stems, so that there is absolutely nothing inside of the steam-chests but the valves themselves, and each one composed of one piece of iron only; by taking off the back bonnets (by removing four tap-bolts) any one of the valves can be taken out without disturbing or altering a single adjustment of the valve-gear. This fact will be appreciated by engineers who are running engines which they are compelled to dismantle every time they examine the valves and valve-seats. The wrist-plate, to drive the four valves, is mounted upon a large substantial bearing, bolted to the side of the cylinder, and drives the valves by means of four small connecting-rods. The exhaust valves are at all times positively connected with the wrist-plate, and the steam valves are always opened by positive connection, but are closed by means of the vacuum dash-pots. The steel catches for opening and liberating the steam valves are made of hardened steel, and arranged so as to give eight wearing surfaces on each piece, without re-dressing or re-tempering. The liberation of the valves for cutting off steam, is effected by means of hardened steel blocks, which are controlled by the regulator, and to the peculiarities of this device is due its uniformity of speed. Reynolds-Corliss Engines are also built with compound or triple expansion, with cylinders arranged in tandem form or side by side.

The entire system of valve gear and regulating mechanism is designed in a way to allow the engineer to either set the valves or to change the position of the knock-off blocks when the engine is running, so by the use of an indicator all of the valves can be adjusted perfectly without stopping the engine. The governor is a very simple form of the well-known fly ball type and is not hampered with any portion of the valve gear; it is free to act at the instant of demand for more or less power, due to changes of the load or steam pressure on the engine; it simply indicates the point of cut-off without holding or driving any part of the valve mechanism.

The resistance offered to the governor is a constant quantity throughout the entire range of the cut-off mechanism, and consists in simply holding two knock-off blocks in position to determine the point of cut-off as indicated by the governor for varying loads and steam pressure, always answering with a precision practically absolute any demands for more or less power.

The following is a record of a test made by Messrs. Chas. A. Pillsbury & Co., merchant millers, of Minneapolis, Minn.," of work performed by mill A engine in one-half of mill for week ending January 30."

Number of barrels of flour ground 15,768

Pounds of coal used 260,653

Pounds of coal, per barrel of flour 16.52

Indicated horse-power 986

Average steam pressure pounds, 83

Average receiver pressure pounds, 11

Average vacuum inches, 25

Temperature of overflow degrees, 108

The engine is a Reynolds' Patent Compound Condensing, with cylinders 32" and 60"x 60," running 67 revolutions per minute. No changes were made in the conditions of the mill-boilers or engine, all the coal fired to boilers was charged to the engine. No allowances or deduction of any kind were made. A Reynolds' independent Steam Power Air Pump and Condenser, and a steam-pump for feeding the boilers were supplied with steam from the same battery of boilers which supplied the engine, and whatever coal was required to make steam to run them is included in the amount charged to the engine. |

|

1890 E. P. Allis & Co., Reynolds-Corliss Engine

1890 E. P. Allis & Co., Reynolds-Corliss Engine

|

|