|

Title: |

1857 Images-Livermore Manufacturing Co., Barrel Making Machinery |

|

Source: |

Transactions of the American Institute of the City of New York 1857 pgs 131-135 |

|

Insert Date: |

3/26/2011 7:47:26 PM |

These machines work up all kinds of sound materials, regardless of variety. Knots and knurls present no difficulty. Wood is worked more like a metal than a fibrous substance. A spurious or an unsound article cannot be employed. Doety materials, or wood effected by dry-rot, is immediately detected, and must he rejected. Hogsheads, barrels, kegs and firkins are manufactured identically equal, hence all the difficulties of stowage are overcome The ultimate strength of barrels and casks is increased at least twenty-five per cent., and yet less material is employed and none wasted; the work of the cooper is made to assume its maximum density and durability.

Every two staves are exactly alike, and each stave is symmetrical, and formed with mathematical accuracy, so much so, that the contents of a barrel or hogshead may be accurately determined from the measurement of a single stave. Casks retain a permanent form, perfectly air-tight, water-tight and flour-tight.

If fifteen or any other number of Livermore's equal and symmetrical staves form a barrel, any set may be selected at random. The use of truss or gauge hoops are not required. A given number of staves placed promiscuously, form a cask mathematically accurate, and do not require being marked.

In order to form an adequate idea of the importance of this invention, patented in this country and in Europe, it should be considered that the wheat and other grains raised in the United States and the Canadas would require, in transportation, nearly a hundred millions of barrels and casks annually; while in Europe, more than a thousand millions of barrels, hogsheads and casks are required annually.

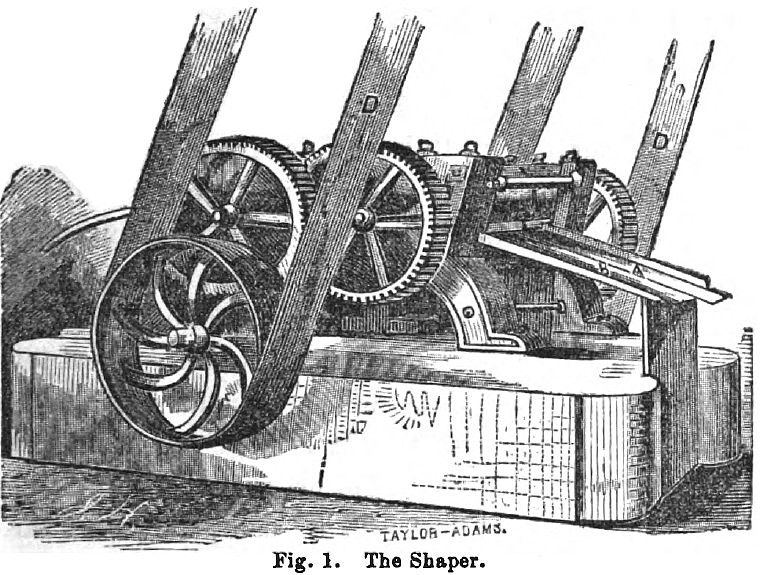

The invention consists of three separate machines, viz: A Shaper, Jointer and Head-cutter. The staves, after being sawed and seasoned, are planed on one side with any ordinary planing machine, reducing them to a uniform thickness. They are then passed through the shaper, which process gives them the proper form.

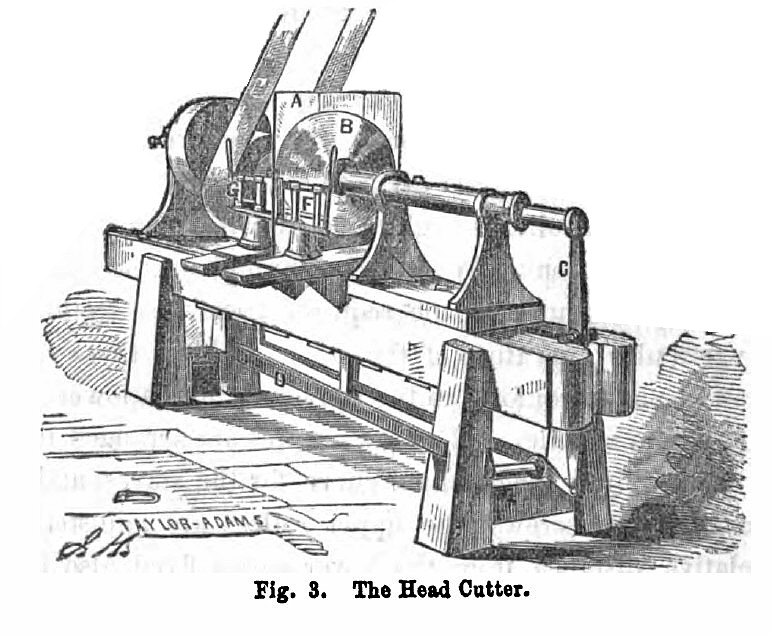

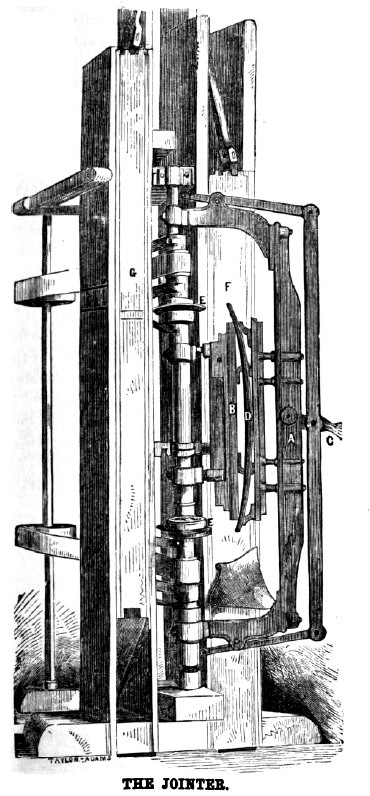

In the manufacture of casks, the staves are heated for four or five minutes, previous to passing through the shaper, which enables them to retain their firmness and required shape; but this is not necessary in the manufacture of ordinary barrels. The staves are then placed in the jointer, where, by an ingenious process, they are jointed, chamfered and crozed, and finished in the most perfect manner, ready to be set up at any future time. The head-cutter is very simple in its construction and design; it turns out a perfectly finished head, that will fit exactly the square groove in the staves, entirely superseding the necessity of lining hoops.

One shaper, four jointers, and one head-cutter, with the labor of eight men and five boys, will turn out staves and heads for five hundred barrels a day. These staves and heads, in transporting, occupy not more than one eighth the space of a barrel set up, and hence the expense is correspondingly diminished. When they arrive at the place of destination, they require but small storeroom, and need not be set up till wanted. The above figure represents the Shaper, which consists of a series of five pairs of convex and concave rollers, so arranged with respect to each other, and so shaped, as to give the staves the requisite curve, and at the same time compressing the wood in such a manner that the form given to the staves is permanently retained. The first roller is slightly convex, the next has greater convexity, and this convexity increases throughout the series, the last of the series completing the required transverse section and perfectly circular curvature of the stave. Above these rollers, and curved so as to conform to the convexity of the lower series, is another series of rollers. The lower series are arranged to conform to the required longitudinal curve for the staves, and may be adjusted by set screws; the upper rollers are adjusted, and their relative distance from the lower series fixed also by set screws, so as to give the requisite compression to the stave blanks in proportion to their thickness. The transverse curvature of the stave is given by the concavity of the upper and the convexity of the lower series of rollers, and can be varied to any required extent by changing the rollers for those of greater or less convexity or concavity. The longitudinal curviture of the staves may be increased or diminished by operating on set screws before mentioned.

A and B are the staves passing in through the rollers, from which they receive their shape, as shown by a stave leaving the machine at C ; the stave is shown more plainly at D, Figure 2. The belts, D D, Figure 1, drive the machine, and require about two-horse power.

Fig. 2. The Jointer.

A is the outside clamp, B the inside clamp, C the handle, by which the clamp B brings the stave D in the position it holds in the barrel, cask, or hogshead, when set up. The connected parts, A and B, holding the stave D, then are made to pass by the saws, E E, by which the staves are cut the right length, and also chamfered, crozed, and howelled. The clamp is then pressed towards the jointer F, which brings the stave in contact with the knives finishing that side of the stave. It is then passed back to the other side of the jointer G, which finishes the other side; and then by raising the handle, C, the stave is released, and passes through an opening in the floor. The Head Cutter.

A is the wood previously planed down to the required thickness, and held in its position by the plate B, in connection with a lever, C, operated by the foot at D. The wood A, out of which the head has to be formed, and the plate B, are made to revolve by the belt E. The head is then cut and chamfered on both sides at the same time, by the knives F and G, operated by a lever.

About one-half of one-horse power is required to operate the Head-Cutter.

The Heads fit firmly with mathematical exactness, and are formed so much alike, and equal, that it is impossible to misplace them.

Staves for shooks, manufactured by this machinery, require no marking, but a given number of staves necessary for a cask may be set up promiscuously, and they form a perfectly tight joint; while, by any other process truss hoops must be employed, and each stave marked, so that when set up for use, they must occupy the relative position given to it by the manufacturer. The experience of commerce demands for general packing purposes precisely the qualities which the cooper attempts to give a barrel or cask, namely, convenient size for handling, roundness for rolling, projecting chimes to be seized in hoisting, and swelled bulge to allow of tightening by driving the hoops. Economy demands that the whole should be wood in separate pieces; but a due regard to efficiency and tightness requires a high degree of perfection in the workmanship. A silver medal awarded. |

|

1857 Livermore Manufacturing Co., Wood Shaper

1857 Livermore Manufacturing Co., Wood Shaper

1857 Livermore Manufacturing Co., Head Cutter

1857 Livermore Manufacturing Co., Head Cutter

1857 Livermore Manufacturing Co., Wood Jointer

1857 Livermore Manufacturing Co., Wood Jointer

|

|