Image

|

Title: |

1896 Article-Betts Machine Co., Vertical Boring & Turning Mill |

|

Source: |

Machinery Magazine Jan 1896 pg 150 |

|

Insert Date: |

3/22/2011 4:57:12 PM |

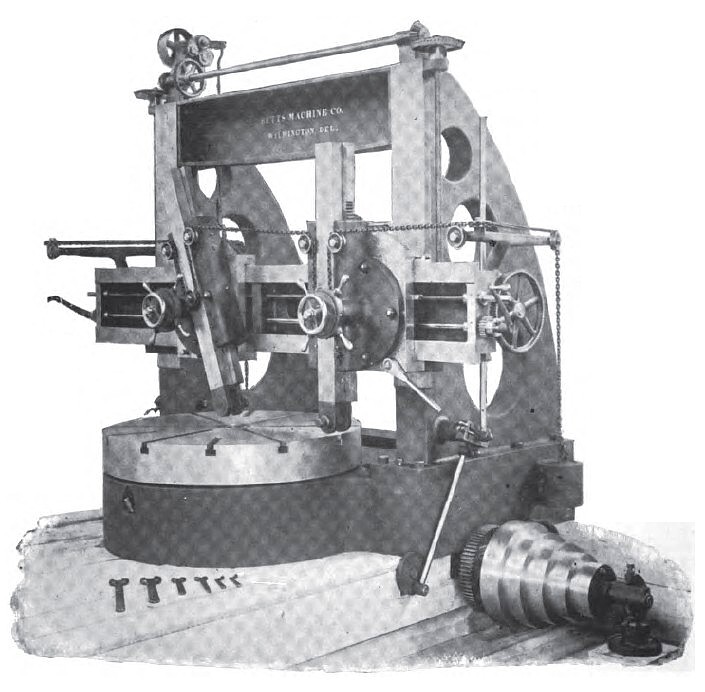

The engraving herewith shows the improved Boring and Turning Mill as recently gotten out by the Betts Machine Company, Wilmington, Del., U. S. A.

The mill is stiff and heavy in all its parts, and is conveniently and rapidly handled. It has the advantage of large ratio of gearing and large cone; of the large number of speeds of table; of the positive and entirely independent feeds and of the perfect counterbalance to each spindle. The bed-plate is of box form, of heavy section, well braced with ample flanges, and has the gearing for driving the table firmly secured thereto. The table is driven by an internal spur wheel and a forged steel pinion, and is attached to a stout and long spindle at its center. The spindle is carried in an adjustable bearing in the bed-plate, while its lower end rests on a steel step and wedge enclosed in another adjustable bearing. On the bottom side of the table is an annular bearing which is a part of the bed-plate, for the sustaining of heavy loads on the table; when light loads are being handled, the wedge under the bottom step can be pushed in by operating a square-ended rod in the bed-plate beside the table, thus raising the table off the annular bearing, allowing it to run lightly for faster speeds. The table is well provided with "T" slots to secure work.

The driving gears are all cut from the solid, and all spur pinions are of forged steel. The pitch and face of the gears are large and have proven very successful in wearing qualities and strength The driving shaft is of large diameter and runs in long bearings. The driving cones are provided with a convenient number of speeds and generous belt width. The uprights are of the box or double plate pattern, have wide faces and long bases. They are amply secured with bolts which fit in T slots in the side pieces of the bed-plate, thus allowing the mill to enlarge its swing. The front ends of the uprights are provided with taper dowels to bring them into alignment again after being moved.

The cross-rail is made deep in its bearing on the face of the uprights and is secured thereto by a long clamp extending its full depth. It is of heavy box section with large wearing surface and has a square lock for the saddles, both top and bottom, thus always taking the strain in a manner to best resist wear and spring. The saddles have a long bearing on the cross-rail, with rapid hand movement by rack and pinions; the face of the saddle is provided with a circular T slot, which receives the bolts, and these secure the index-plates or swivels. The index-plates carry the tool spindles or cutter bars in a slide on their face, and these are also provided with a square lock, as in the case of the cross rail. The tool spindles are provided with a rack and pinion for quick motion up or down, as well as for feeding; the ends of the spindles are provided with a special tool-holder, in which the tool can be fastened and adjusted with as much ease and as great scope as in a lathe. Each spindle is counterbalanced in all positions, and the counterbalance does not interfere in any way with the setting of the index-plates. Two complete sets of feeds are provided, making each saddle as independent of the other as though on separate machines. These feeds cover a wide range, arc many in number and have ample power; they are by hand or power in all directions. The cross-rail is moved by power in all sizes. Provision is made for taking up the wear in both the saddles and tool spindles. Complete details may be had of the makers. |

|

1896 Betts Machine Co., Vertical Boring & Turning Mill

1896 Betts Machine Co., Vertical Boring & Turning Mill

|

|

|

|