|

Title: |

1903 Article-Fosdick Machine Tool Co., Horizontal Drilling Machine |

|

Source: |

American Engineer & Railroad Journal Dec 1903 pg 469 & Milling Machines & Milling Practice 1910 pg 346 |

|

Insert Date: |

3/19/2011 9:48:54 AM |

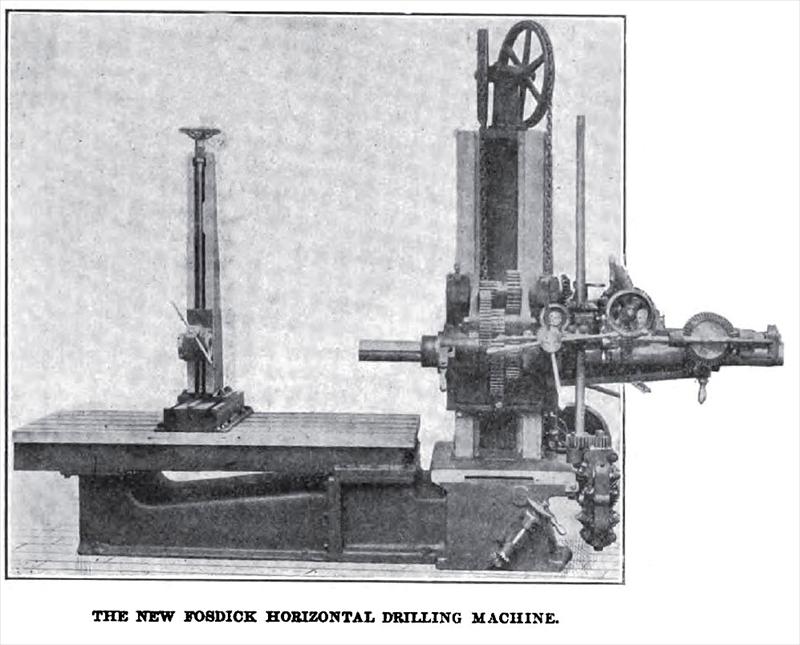

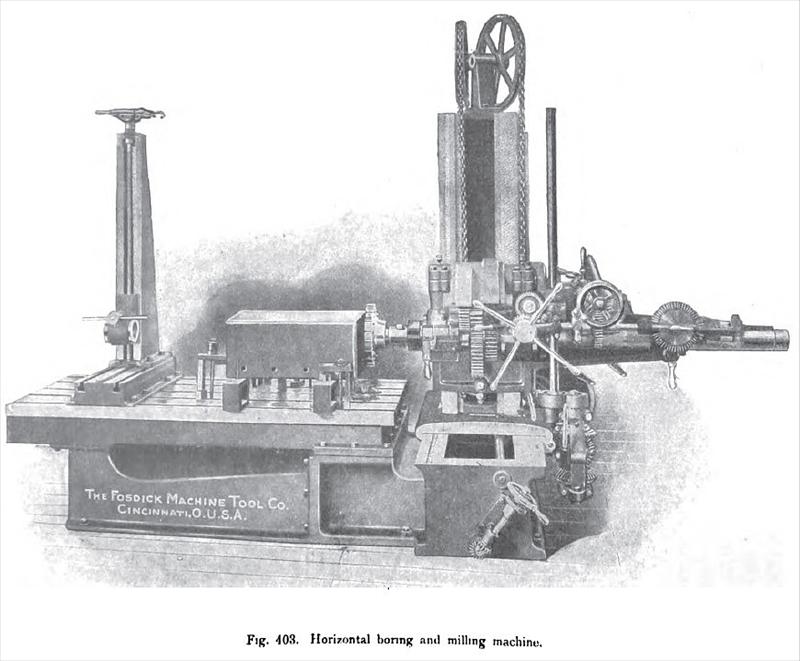

A new departure In the line of drilling machinery has recently been made by the Fosdick Machine Tool Company, Cincinnati, Ohio, in placing upon the market a new drilling machine of the horizontal type, which is coming into such general use for large numbers of complicated machining operations. The new Fosdick horizontal drill embodies many new features of importance which will render it universally adaptable for operations of boring, drilling, tapping, reaming, facing, milling, etc., on both light and heavy work, in the most economical manner possible, all of the above mentioned operations being possible in one setting of a piece of work fastened to the table, insuring the most accurate and profitable results. This half tone engraving presented herewith was made from a photograph of the machine and shows its well proportioned design.

The drive for the machine is made through a splined shaft, traversing the driving cone on the rear of bed, and leading to the gearing at the base of the column. The column which carries the spindle head, has a horizontal movement on the bed by hand or power in both directions, and is supplemented by a quick forward and return motion by power, operated by the hand-wheel conveniently located on the front of bed.

The spindle head has a vertical movement on the column by hand or power in both directions, being well counterbalanced and provided with a safety chain, and for quick adjustment is operated through a rack and pinion with ease by the pilot wheel on the front of the spindle head. The spindle runs in adjustable bronze bearings and has a thread cut on its projecting end to receive chucks, large milling cutters, facing heads, etc., for very heavy work. It can be made to revolve in either right or left hand directions by means of a reverse lever; this is very convenient for facing, tapping, milling and other operations.

The spindle bar, which passes through the hollow spindle, is 4 ins. in diameter, has 22 ins. traverse and is fitted with a No. 5 Morse taper to receive drills, taps, reamers, boring bars, milling cutters, etc. It has power and hand feed in both directions, may be operated from the pilot wheel for quick adjustment, and can be securely clamped for face milling purposes. For very heavy work the cutter, or boring bar, is secured by a cotter fitted to the spindle bar.

All the feeds, for horizontal traverse of column, and horizontal and vertical feeds of spindle head, are taken from the spindle; they are positive-geared and reversible, eight in number by hand or power, and are arranged in geometrical progression from .007 to 1/4 in. per revolution of the spindle. The spindle speeds are ten in number, arranged in geometrical progression from 4 to 260 rev. per min. The gear ratio from the cone-driving shaft to spindle is 2 2-3 to 1. and the ratio of back gears is 13.6 to 1.

SPECIFICATIONS.

Diameter of spindle bar 4 Ins.

Diameter of spindle nose 6 ins.

Traverse of spindle 22 ins.

Vertical adjustment of head on column 36 ins.

Horizontal adjustment of column on bed 32 Ins.

Maximum distance table to center of spindle 44 Ins.

Minimum distance table to center of spindle 7% Ins.

Size of table 31 x 72 ins.

Tight and loose pulley on countershaft 16 x 4 Ins.

Speed of countershaft 228 rev. per min.

Width of belt on cone 3% lna.

Distance end of pulley shaft to end of bed 9 ft. 9 Ins.

In tance end of spindle to end of table 12 ft. 6 Ins.

Total height of machine 8 ft.

Net weight of machine 12,000 lbs. |

|

1903 Fosdick Machine Tool Co., Horizontal Drilling Machine

1903 Fosdick Machine Tool Co., Horizontal Drilling Machine

1910 Fosdick Machine Tool Co., Horizontal Drilling Machine

1910 Fosdick Machine Tool Co., Horizontal Drilling Machine

|

|