|

Title: |

1890 Image-Wheelock Engine Co., Steam Engine |

|

Source: |

The Practical Steam Engineer's Guide 1890 pgs 66 & 67 |

|

Insert Date: |

3/2/2011 6:52:41 PM |

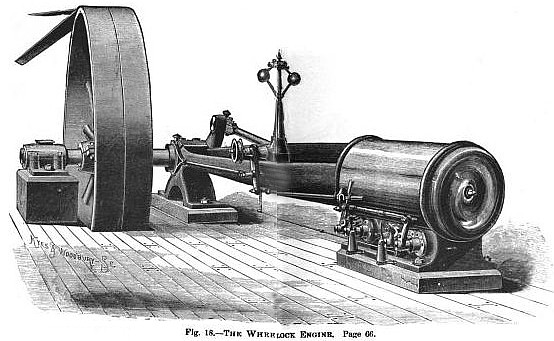

The Wheelock Engine.

The economy of variable or automatic cut-off engines has been so well established that no remarks in favor of the general system are required. To overcome the objection of complication for common Use is a desideratum well attained in the machine herewith shown.

By reducing the number of parts and placing all the mechanism for operating the valves on the outside of the steam-chest, every defect may be at once detected.

Valves are used, which are suspended on hardened steel trunnions, or stems, and hardened steel bushings, and are located directly under the bore of the cylinder at each end, thereby reducing the clearance to the smallest possible amount. The valves and seats are made tapering in their general diameter, and the pressure of steam comes on one side, which also acts to keep the collar in contact with the sleeve. Steam is admitted and exhausted by a single valve, and any variation of the load is at once communicated through the action of the governor, which has entire control over two cut-off valves, or wipers, by a simple mechanism, the construction of which is such is such as to insure entire uniformity of speed under extreme variation of load. A cavity in face of the cutoff valves allows a double admission and closing. A very perfect result is claimed as due to the fact, that the valves are suspended on the hardened steel trunnions and bushings, thereby maintaining the valve in a central position. Attention is called to the fact that the cut-off does not control the time of admission or lead to the cylinder, but is well open before the main valve is ready to open the induction port. This is claimed as a great advantage, especially where steam follows but a small portion of the stroke. The explanation is, that if the cut-off opens but a crack, as in cases where the lead is controlled by the cut-off, the mechanism is not sufficient to close it, and steam sizzles through during the whole stroke, thereby making speed irregular. The valve-gear is constructed in the simplest form of the ordinary eccentric rod, and is made to disengage at the pleasure of the engineer, by which result the engine can be worked by hand, either forward or backward, with perfect ease, a point very desirable in practice.

By reference to Fig. 19, showing valve gear, it will be noticed that the cut-off is worked from the main valve crank. The pin being an eccentric bolt makes adjustment very handy. This attachment produces the celebrated wrist-plate motion, without its complications.

The entire adjustability of the valves to their seats is secured by a peculiar arrangement of the steel bushings (which can be driven in or out as required), the inner end forming a joint against the steel valve-stem or trunnion, entirely obviating the necessity of any stuffing-box. These steel stems have been found in practice to wear endwise in about equal ratio with the surface of the valves and their seats; and as the valves are suspended with the surfaces in but slight contact, while the pressure inclines the valves to their seats, great durability is obtained. The steam-chest is located underneath, and forms a part of the cylinder, as is also the exhaust passage. The latter is entirely separated from the steam-chest, and in no way influences the live steam, while easily disposing of any accumulation of water.

The cylinder has but two ports, and the valves being suspended, do not gouge out the seats, nor do the seats need to be recessed. The object of this construction is to get the effect of steam balancing without the objections that apply to that method.

In the production of the Wheelock engine, it has been the aim of the manufacturer to produce an engine with the most advantages and the fewest disadvantages to be found in any machine now offered to the public. His success in that direction may be measured by the high position the engine has attained where it is known.

The arrangement of the valves not only reduces the clearance to a minimum, but guards against a waste of steam through the exhaust port, if there be a leakage in the cut-off valve.

The cylinders of these engines are fitted with the Wheelock piston and steam packing, which have shown gratifying results in use during sixteen years.

The stop motion in use in these engines effectually prevents the engine from running too fast, in case of accident to the governor. |

|

1890 Wheelock Engine Co., Steam Engine

1890 Wheelock Engine Co., Steam Engine

|

|