|

Title: |

1884 Images-Wright Steam Engine Works, Steam Engine |

|

Source: |

The Engineer's Handy Book 1884 pgs 36 & 37 |

|

Insert Date: |

2/26/2011 1:01:10 PM |

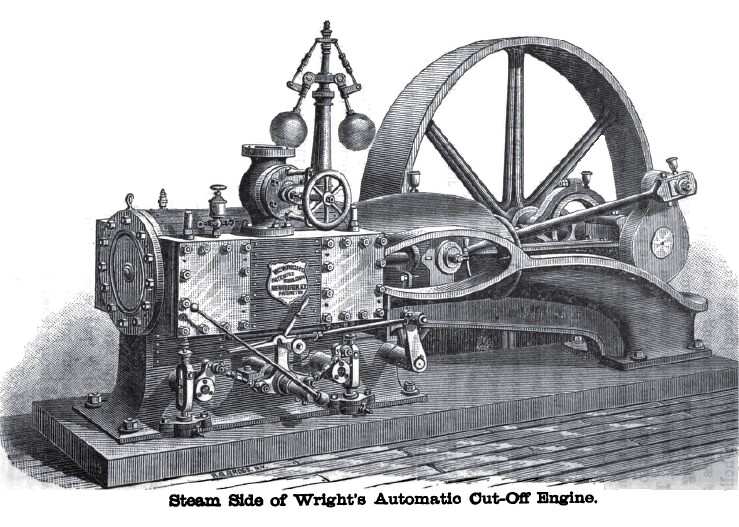

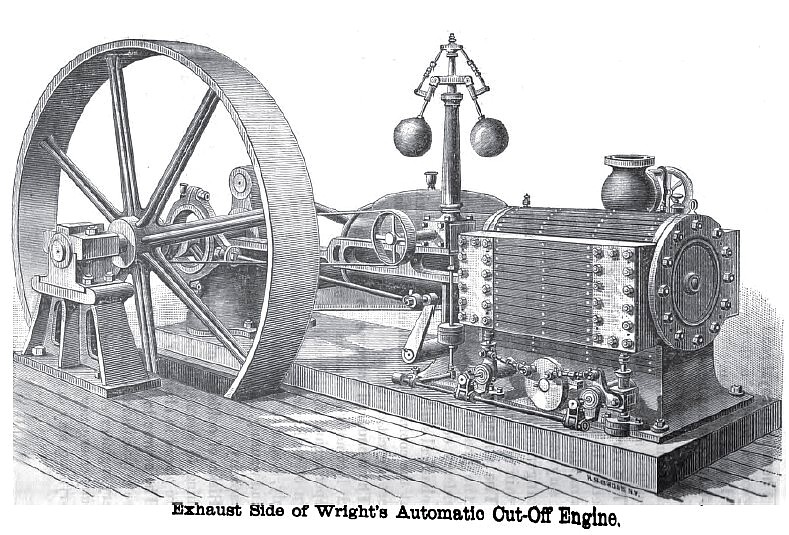

WRIGHT'S AUTOMATIC CUT-OFF ENGINE.

The cuts on pages 36 and 37 represent a front and back view of Wright's Automatic Cut-off high-pressure engine, the bed-plate or housing of which, as will be observed, is radically different in design and general appearance from any other in use in the country. The ordinary guides are dispensed with, and a guiding-cylinder, which is bored out on a line with the centre of the steam-cylinder, for the direction of movement of the cross-head, substituted. There are lateral openings in the sides of the guiding-cylinder, through which easy access to the cross-head and piston-rod may be had. From the front of the guiding-cylinder to the point where it meets the base, the frame is made in the form of an inclined concave-convex trough of sufficient depth to permit the free movement of the connecting-rod. The trough has the upper edge of one side continued in a plane coinciding with the centre of the cylinder, from the latter to the enlargement formed to receive the bearing of the crank-shaft. The opposite side of the trough extends from the guiding-cylinder, with a gradually descending curve, to the base, into the upper portion of which it gracefully merges.

The steam-cylinder rests on a separate bed or foot, which sustains all the bearings for the valve-gear, and which is placed on a level with the pillow-blocks and main bed-plate, to which it is securely bolted and doweled. There are four valves, two steam and two exhaust, which are of the gridiron or multiport-slide pattern. They work vertically in chests cast upon the cylinder, the two upon the front being for the induction cut-off and expansion, and those on the back for the eduction or exhaust. The motion for the steam- and exhaust-valves is derived from a single eccentric, which is so arranged as to give a quick movement to the valves in opening, and a slow movement when lapping. The stems of the steam-valves are connected with yokes having at their lower ends dash-pots, which act as guides. These yokes are operated by steel slides protruding through the ends of hollow rocker-arms, and acting upon the swinging toes held in the yokes. The slides have a diagonal slot, in which works a feather on a rod, which has a longitudinal movement through the hollow rocker-arms with which the governor is connected. By this longitudinal motion through the diagonal feather and slot the slide is automatically set, to engage the swinging toes, more or less, according to requirements, to give the valve its proper lift, and release it on the chord of an arc.

The governor is of a kind peculiarly adapted to these engines, as it is very powerful and sensitive. It rests on a bracket, or shelf, cast on the side of the bed-plate; the rod being connected with a lever which is fastened to the governor-shaft. This shaft carries two forked arms, which take hold of the small rods running through the hollow rocker-shafts. These rods are enlarged at their ends, where they carry the adjustable slides, which operate the steam-valve yokes.

These engines are made of the best material, and fitted and finished in the most thorough and workmanlike manner., The pistons are fitted with self-adjusting steam packing-rings, the lower half of piston body, between the packing-rings, being fitted with a brass shoe, which carries the weight of the piston, and can be so accurately adjusted that the piston must move central with the bore of the cylinder. The piston-rods, wrist- and crank-pins, and valve-rod are made of steel, and the boxes of the best machine brass: The connecting-rods and crank-shafts are made of the best hammered iron, and the pillow-blocks are lined with anti-friction metal. All the rubbing, revolving, and vibrating surfaces are of ample proportions, and fitted with great accuracy and precision.

The Wright Engine has undergone more changes in design and general appearance, since it was first introduced to steam users, than any other engine in the country. The manufacturer seems to be under the impression that, however much he might alter, he always discovers new defects in his engine, and he appears to unsymmetrical, and expensive, and perhaps less economical than most other automatic cut-off engines. |

|

1884 Wright Steam Engine Works, Steam Engine

1884 Wright Steam Engine Works, Steam Engine

1884 Wright Steam Engine Works, Steam Engine

1884 Wright Steam Engine Works, Steam Engine

|

|