|

Title: |

1874 article - Mellor & Orum molding machine (spindle shaper) |

|

Source: |

Manufacturer & Builder, January 1874. |

|

Insert Date: |

1/17/2012 7:21:37 PM |

Here is the complete text of the article:

MACHINE FOR MOLDING FURNITURE

Some years ago we saw in a furniture manufactory in Philadelphia the operation of a machine by which different forms of moldings could be cut rapidly and neatly, no matter what the shape of the object which was to be ornamented or surrounded by a molding. Evidently such a machine bears the same relation to a common molding planer that wood carving bears to common planing. In fact, work can be accomplished with such a machine in the most rapid and easy manner, which otherwise would be only possible by the elaborate and costly process of carving by well-trained and expensive workmen.

We are now informed that that same city of Philadelphia was among the first to use these machines. The first machine built there of which there is any authentic account was made by Charles H. Mellor, and used by Messrs. Hart, Ware & Co., as early as the year 1851. Mr. Mellor has therefore more than twenty years experience in the manufacture of this class of machinery. This machine was similar to the so-called double-head machine now in use, and was at once adopted by several of the manufacturers.

Shortly after the introduction of these double-head machines, a single spindle machine was brought into notice, which ran but one way and on which was used a cutter similar in construction to the ordinary milling tool. This kind of cutter being found to produce rough work in running against the grain of the wood, was improved so that it could run and cut either way. This kind of cutter is similar to the Friezing bits now used in some localities, and had the additional advantages of being safer to operate, capable of being adjusted with more facility, thus saving time, which is an important item; and also by reason of the molding of the cutter being on the outside there was no possibility of changing the molding in sharpening, as it could be sharpened from the inside. It was quite extensively adopted by the Philadelphia manufacturers, but they soon discovered that it possessed the disadvantages of working very hard, the angle of the cut being very obtuse, and also of preventing the free escape of the cuttings or shavings. A number of attempts at still further improvement followed, which culminated in the production of

the concave reversible cutter.

The advantages possessed by this cutter are many and various. It is an improvement on the solid cutter in the respect that while it has the molding face on the outside, it has also a very acute cutting edge,giving a paring cut instead of a square cut; it also permits of the free escape of the cuttings. It is also an improvement on the straight knife cutters, inasmuch as it can be worked in a much smaller radius, and can be adjusted or set much more quickly.

The cutter at first met with considerable opposition, because of its apparent frailty as well as its increased cost; but after persistent effort it came to be adopted by several of the larger establishments and soon won its own way into popular favor, being considered as good if not superior to all others.

These cutters are made from forgings of the best English cast-steel, being first turned into shape, then portions cut out, leaving two or more wings, which are cleared on the outside and beveled back to give an acute cutting edge. When used they must be sharpened on the inside, so as to retain the shape of the molding.

After having thus described the cutters, we shall proceed to a description of the machine on which they are used. The first machines manufactured were made with wooden frames, having a central vertical spindle running in two ordinary clamp boxes. The next improvement was to connect the boxes so as to prevent any jar of the frame from throwing them out of line. Then finally the iron frame as now manufactured was adopted.

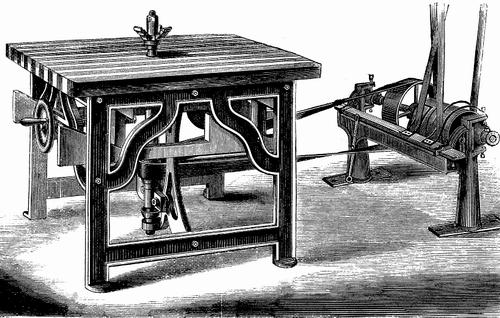

In our adjoined Fig. 1 such a machine is represented as made by Mellor & 0rum, 448 North Twelfth street, Philadelphia. It consists of an iron frame for base, carrying a wooden table top, out of the center of which an axis protrudes, which carries the cutter separately, represented on a larger scale in Fig. 2. The molding is made by the rapid rotation of this cutter, which may turn in either direction, cutting from both sides, so as to cut always with the grain of the wood. It may be easily raised or lowered so as to adapt itself to the requirements of the case; and other kinds of cutters for the production of differently shaped moldings may be substituted. At the right of Fig. 1 the best manner of connecting the gearing from the top is represented; but the power may also, and sometimes in a similar way, be taken from under the floor if there is shafting there.

The prices of these machines vary from $80 to $l75, according to less or more complete condition; while the rotary cutters cost $2.50 and upward each, according to less or more elaborate kind of molding they produce.

We must add in closing that Messrs. Mellor & 0rum produce testimonials by the dozen from parties in Philadelphia and elsewhere who have used these machines for several years with the utmost satisfaction, and no wonder, because they are all fitted up in the best manner, all the joints being planed and firmly bolted, the counter-shaft being constructed so that the two hangers are connected by an iron bar, making the whole affair very rigid. They have wooden table tops made of alternate strips of walnut and cherry. Two styles are manufactured; one with the table to raise and lower and the other with the spindle to raise and lower. The spindle is fitted up with two chucks, one 5/8 of an inch in diameter, and the other 3/8 of an inch in diameter. The 3/8-inch chuck is especially adapted to small work, such as brackets. The 5/8-inch chuck is sufficiently strong for any ordinary work. The spindle itself is made of steel, with a wooden pulley having iron flanges and ends, and is very light and durable. The machine and cutters are now being used in some of the largest car, furniture, and sash and door establishments in the United States.

Patent # 80,648 |

|

Fig. 1 - Improved Universal Molding Machine

Fig. 1 - Improved Universal Molding Machine

Fig. 2 - Improved Molding cutter

Fig. 2 - Improved Molding cutter

|

|