|

Title: |

1902 Article-Buffalo Forge Co., Downdraft Forge |

|

Source: |

Iron Age 02 Jan 1902, pg. 49 |

|

Insert Date: |

2/18/2011 1:27:17 PM |

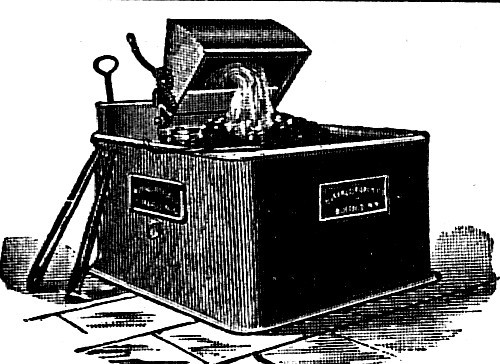

The Buffalo Improved Forge.

By the down draft method of forge construction, as introduced by the Buffalo Forge Company of Buffalo, N. Y., the smoke and gases are immediately and completely withdrawn by means of the down draft suction through an adjustable hood and underground tile piping. In-deed, there is no escape of gases, fumes or smoke from the larger fire. The cast iron hoods are adjustable to dif-ferent positions, according to conditions at the fire. Fumes of hard coal, coke and furnace fires, which are a menace to the smith's health, are rapidly eliminated by the thorough exhaust, and the forge shop atmosphere is as pure as the best ventilated machine shop. The val-uable space and light about the forge are not obstructed

by inefficient telescopic hoods, which are subject to fre-quent renewals.

The illustration shows the latest design for the Buf-falo down draft forge. This forge stands 27 inches to the top of fire pan, which is 24½ a 47½ inches. It has a water tank 6 x 47 inches and 10 inches in depth, and a coal box 10 by14 inches and 47½ inches long. It is also furnished with tool rack, a blast gate, an improved anti-clinker dumping tuyere, and down draft smoke ex-haust hood. This forge, with the exception of the down draft hood and anti-clinker dumping tuyere, which are of heavy cast iron, is constructed entirely of heavy gauge steel plate, and is thoroughly braced. It is best adapted to medium work, and also well suited to light and heavy forging. |

|

1902 Buffalo Forge Co., Downdraft Forge

1902 Buffalo Forge Co., Downdraft Forge

|

|