|

Title: |

1891 Article-Swain Turbine & Mfg. Co., Swain Turbine Water Wheel |

|

Source: |

Inland Massachusetts Illustrated, 1891, pg 260 |

|

Insert Date: |

9/19/2023 7:34:47 PM |

|

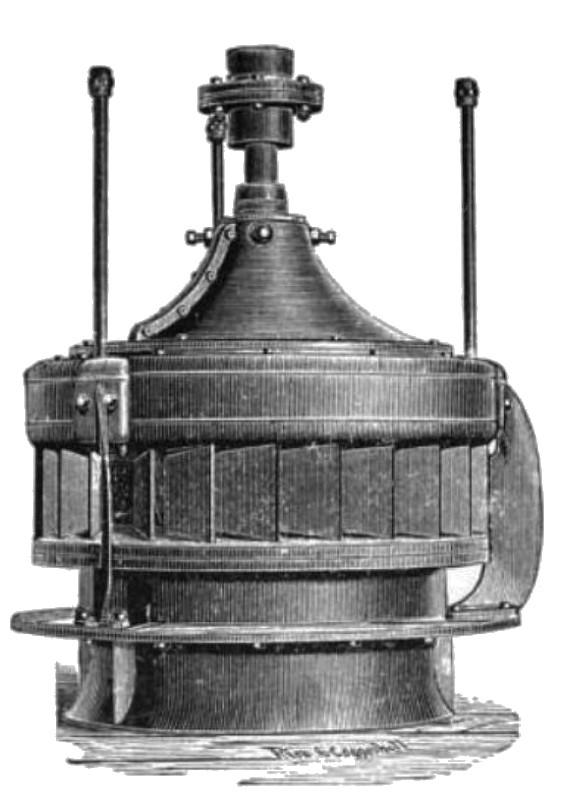

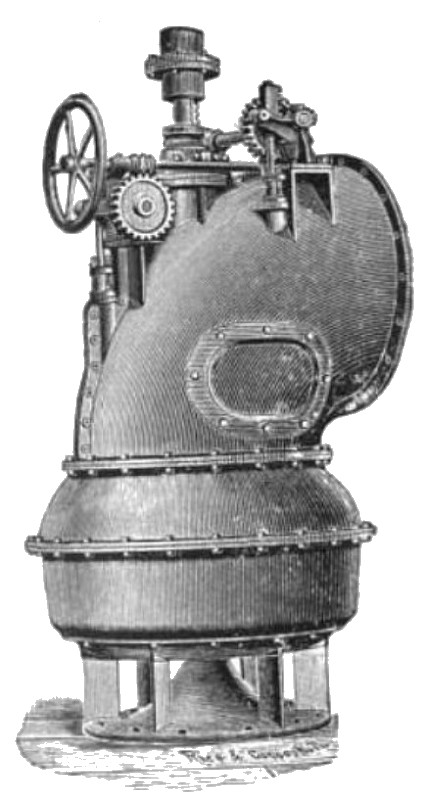

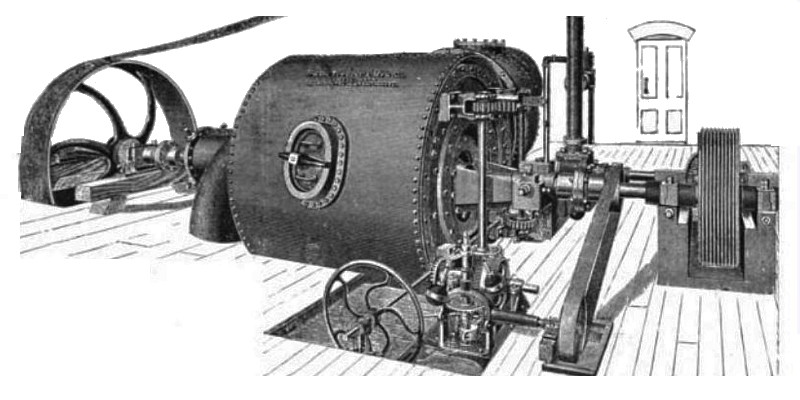

The Swain Turbine is no new and unproved experiment, but an established success of many years standing, ranking with the best and most generally used water-wheels extant. The invention of A. M. Swain, this wheel has been constructed at Nashua, N. H., by the Swain Turbine Company, and finally by the Swain Turbine and Manufacturing Company, incorporated under the laws of Massachusetts in 1874; capital stock $125,000. For some years past Mr. A. F. Nichols has been treasurer and general manager, making the patterns and castings at his foundry, No. 10 Willie Street, Lowell, and shipping the same to Nashua, where the machinists' work is done and the wheels finished and made ready for delivery. They are held in high estimation by water-using mill owners all over the United States, and their popularity in this vicinity and throughout New England is attested by the great number employed by leading manufacturing corporations here and elsewhere, the Merrimack manufacturing Company having one, the Hamilton Manufacturing Company two, the Boott Cotton Mills nine, the Lawrence Manufacturing Company five, the Massachusetts Cotton Mills eight, the Wamesit Power Company one, the Middlesex Company two, while a large number are in constant and satisfactory use at other points, among the owners being the Pacific Mills, the Russell Paper Company and others at Lawrence; Moses T. Stevens & Sons, Haverhill and Andover; the Warren Cotton Mills, West Warren; the Paul Whitin Manufacturing Company, Northbridge; the Washburn & Moen Manufacturing Company, Worcester; the Worthy Paper Company, Mittineague; Byron Weston, Dalton; the Lancaster Mills, Clinton; C. G. Sargent's Sons, Graniteville; S. D. Warren, Boston; Manchester Mills, Manchester, N. H.; the Underhill Edge Tool Company, Nashua, N. H.; the Cumberland Mills, Cumberland, Me.; B. B. & R. Knight, Providence, R. I. (twenty-one); the Pawtucket Hair Cloth Company, Pawtucket, R. I.; Stephen Sanford, Amsterdam, N. Y.; Cohoes Gas Light Company, Cohoes, N. Y.; Republic Iron Company, Marquette, Mich., and the Camperdown Cotton Mills, Greenville, S. C. August 3, 4, 5, 6 and 7, 1874, at the Boott Cotton Mills, James B. Francis, C. E., the well-known Lowell civil engineer, tested a seventy-two-inch Swain turbine, with results thus technically stated: "From 9-inch gate to 13.08-inch gate, or say from about two-thirds gate to full gate, the maximum co-efficient of useful effect varies from 0.828 to 0.839, or about one per cent.; the velocity of the exterior circumference of the wheel relatively to the velocity due the head, corresponding to the maximum coefficient of useful effect, being for 9-inch gate about 0.720, and for full gate about 0.765. At half-gate the maximum coefficient of useful effect is about 0.78, at a relative velocity of about 0.68. At one-quarter-gate, the maximum coefficient of useful effect is about 0.61 at a relative velocity of about 0.66." Mr. A. F. Nichols, who now owns the majority of the stock and controls the Swain Turbine and Manufacturing Company and its output, has been engaged in the iron and brass foundry business here for nearly thirty-three years. From 1858 to November 1, 1890, he was junior member of the firm of Cole & Nichols, proprietors of the Lowell foundry, of which he is now sole owner. The Lowell foundry plant, situated at No. 10 Willie Street, foot of Dutton, comprises a two-story frame building 70x174 feet, connected with which are sheds, yards, etc., the whole covering an area of 100x450 feet. The equipment of both foundry and pattern shop is complete, including ample steam power; from forty to fifty hands are employed here, and the output of light and heavy machinery and brass castings is worth from $60,000 to $70,000 per annum. These include driving-wheel lathes, axle and car-wheel lathes, pumps, shafting, hangers, pulleys, and castings for Swain turbines, in the finishing and fitting-up of which from twenty to twenty-five men are employed at Nashua. Considerable of the work done in the two establishments is exported to other countries, Mexico and Australia being the best foreign consumers. |

|

1891 Swain Turbine & Mfg. Co., Swain Turbine Water Wheel

1891 Swain Turbine & Mfg. Co., Swain Turbine Water Wheel

1891 Swain Turbine & Mfg. Co., Swain Turbine Water Wheel

1891 Swain Turbine & Mfg. Co., Swain Turbine Water Wheel

1891 Swain Turbine & Mfg. Co., Swain Turbine Water Wheel

1891 Swain Turbine & Mfg. Co., Swain Turbine Water Wheel

|

|